Container type super power load box

A super-high-power, container-type technology, applied in the direction of measuring devices, motor generator testing, power supply testing, etc., can solve problems such as inconvenient use, high surface temperature of devices, and open flames, etc., to ensure safety, high integration power, and convenience The effect of assembly and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

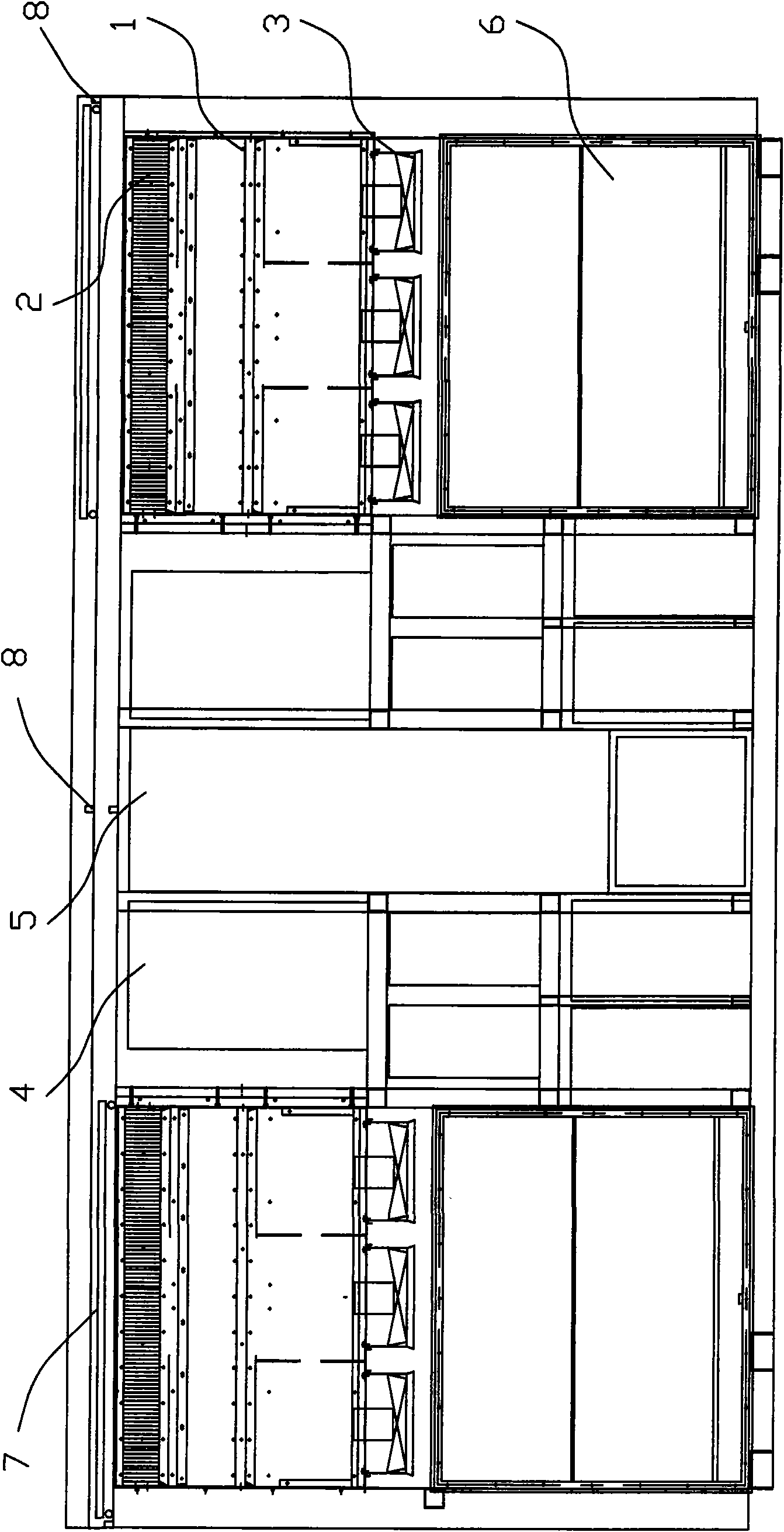

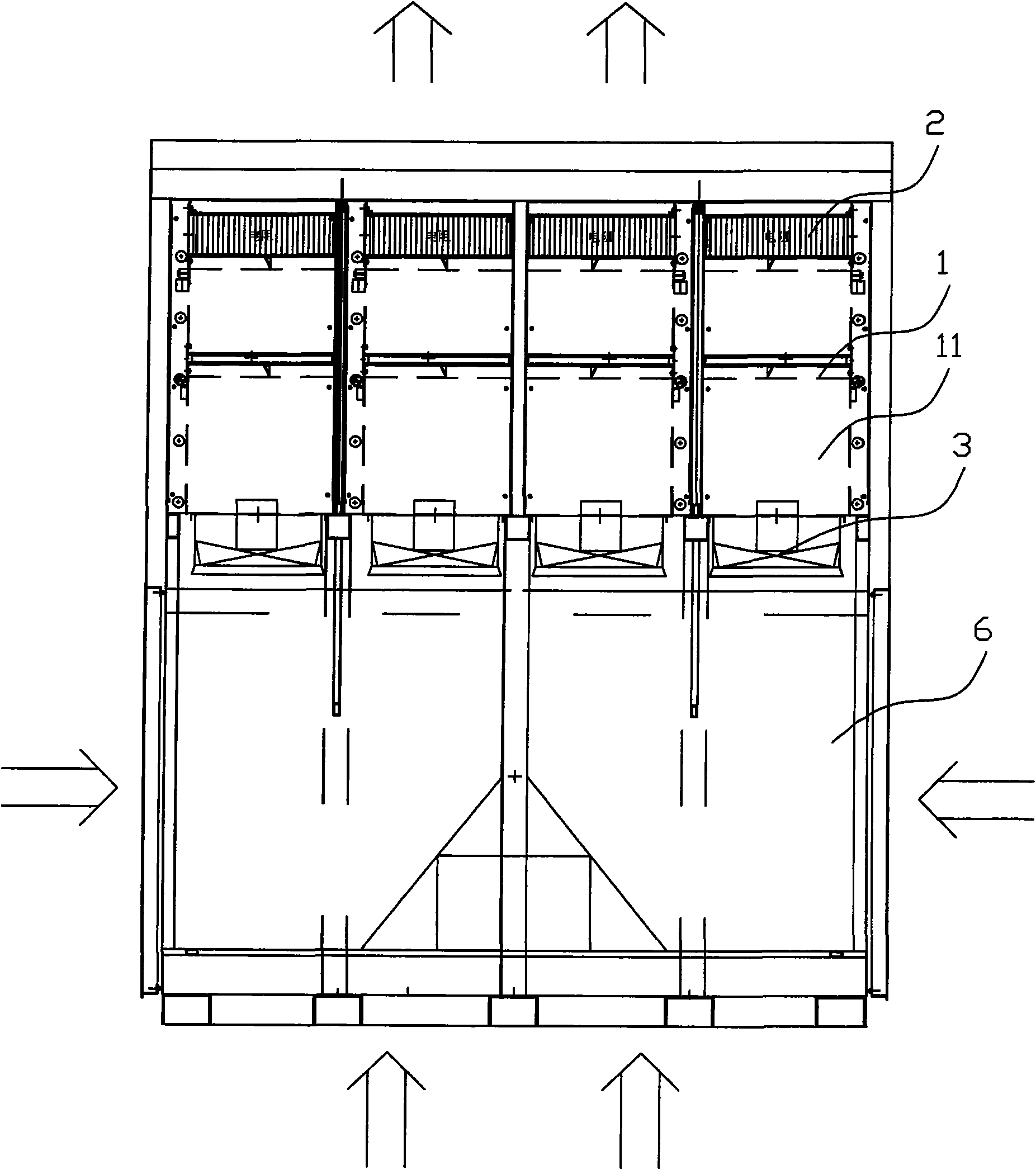

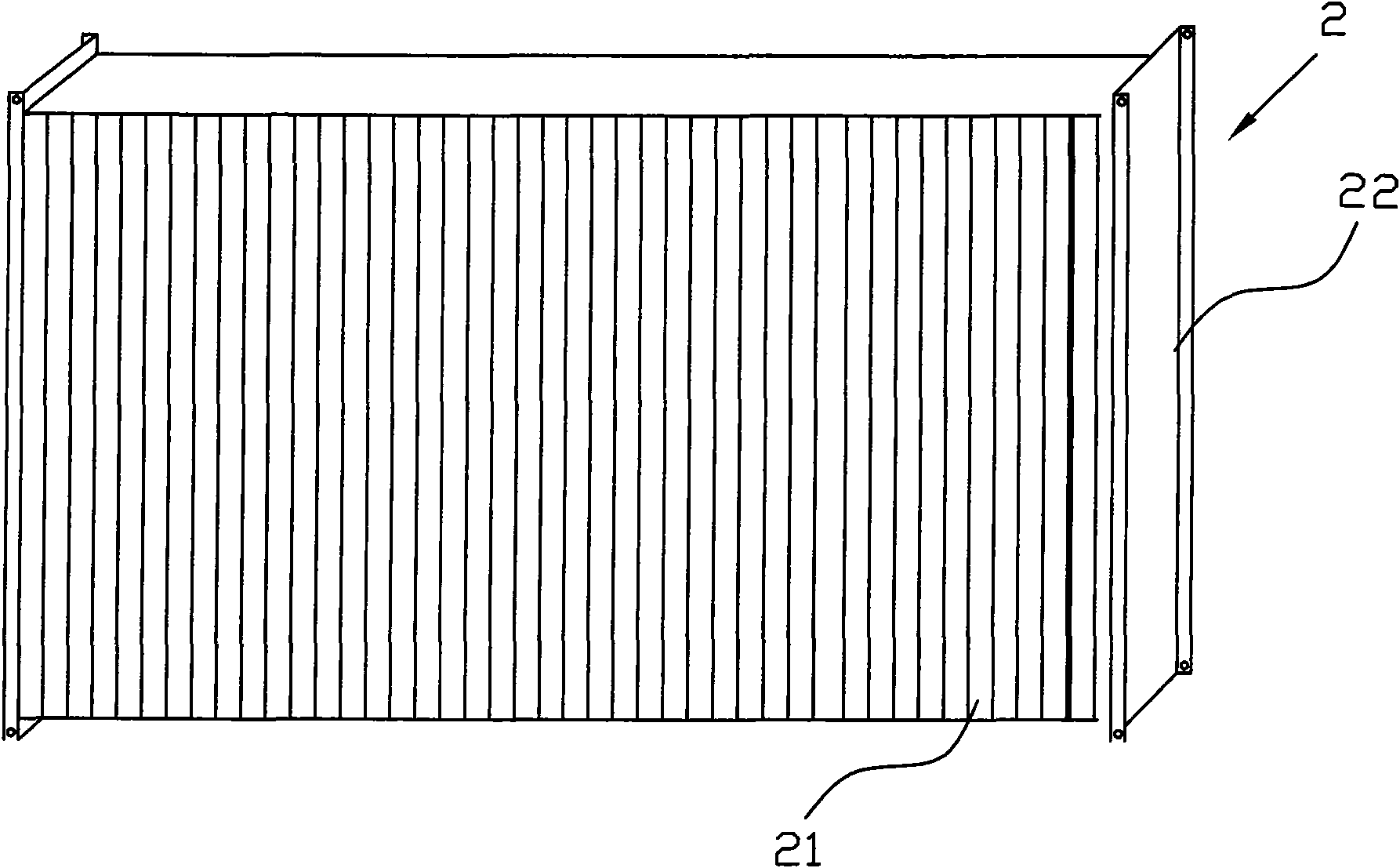

[0026] Such as Figure 1 to Figure 4 As shown, it is an embodiment of the present invention, and the load power of the ultra-high-power load box made of a 20-foot standard container is 4000KVA. The standard container is provided with 8 independent resistance boxes 1, and the resistance boxes are arranged on the upper part of the container. The size of each resistance box is 1440*900*470mm, and there are two PTC integrated resistors 2, and the integrated power reaches 500KW. The length of each PTC integrated resistor 2 is 660 mm, the height is 126 mm, and the width is 450 mm. Vertical ventilation gaps 21 are evenly provided between the resistor sheets of the PTC integrated resistor 2 . The PTC integrated resistor 2 is arranged on the resistor bracket 22, and the resistor bracket is fixed on the inner wall of the resistor box. The PTC integrated resistor is electrically connected with the power distribution system 4 and the control system 5 . The power distribution system and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial dimension | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com