Method of treating coffee cherries, green coffee beans, roasted coffee beans, and coffee drink

A technology of coffee fruit and coffee beans, which is applied in the fields of green coffee processing, coffee, food science, etc., and can solve problems such as the decline in the quality of coffee beverages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0057] The method for processing coffee cherries of the present invention includes a refining process of separating and refining green coffee beans from coffee cherries. More specifically, the method of the present invention includes: (1) washing and sorting processes; (2) steam treatment processes; (3) Rapid cooling process; (4) fermentation process; (5) drying process and (6) refining process. These steps are described below.

[0058] The method for processing coffee cherries of the present invention is to sequentially carry out (1) washing and sorting process to (6) refining process on the picked coffee cherries. In addition to (2) steam treatment process and (6) refining process, if necessary, any optional process can be omitted, or in appropriate cases, the method can also be processed by other processes other than process (1) to process (6). method to proceed.

[0059] (1) washing and sorting process; (2) steam treatment process; (3) rapid cooling process; (4) fermenta...

Embodiment 1

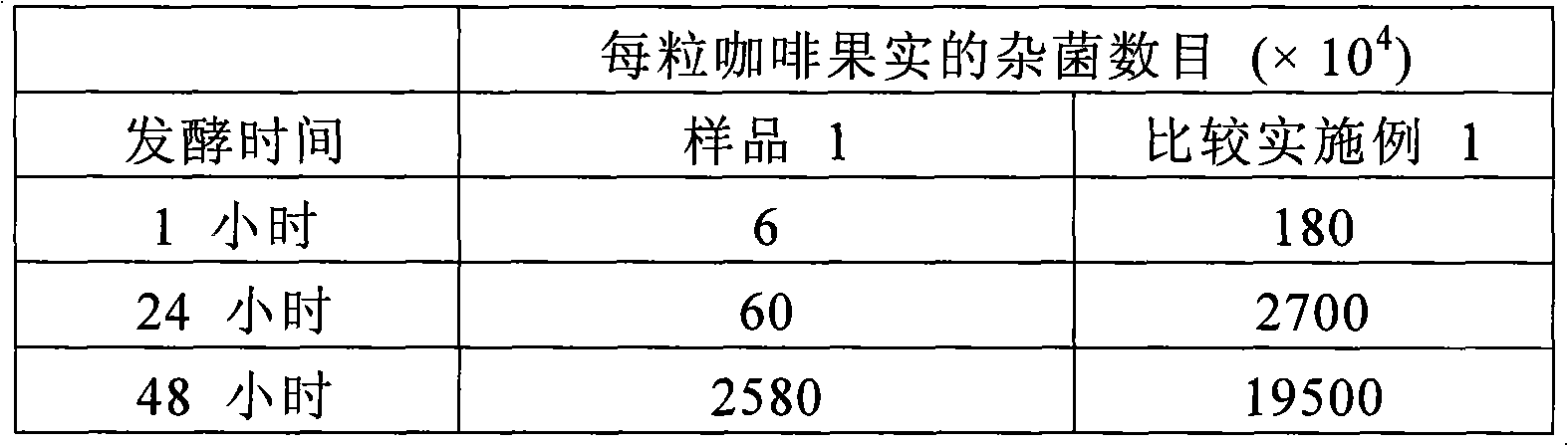

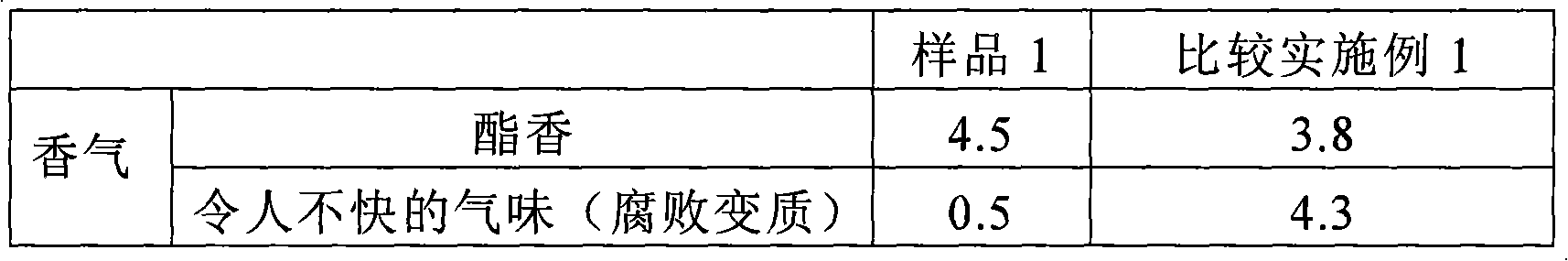

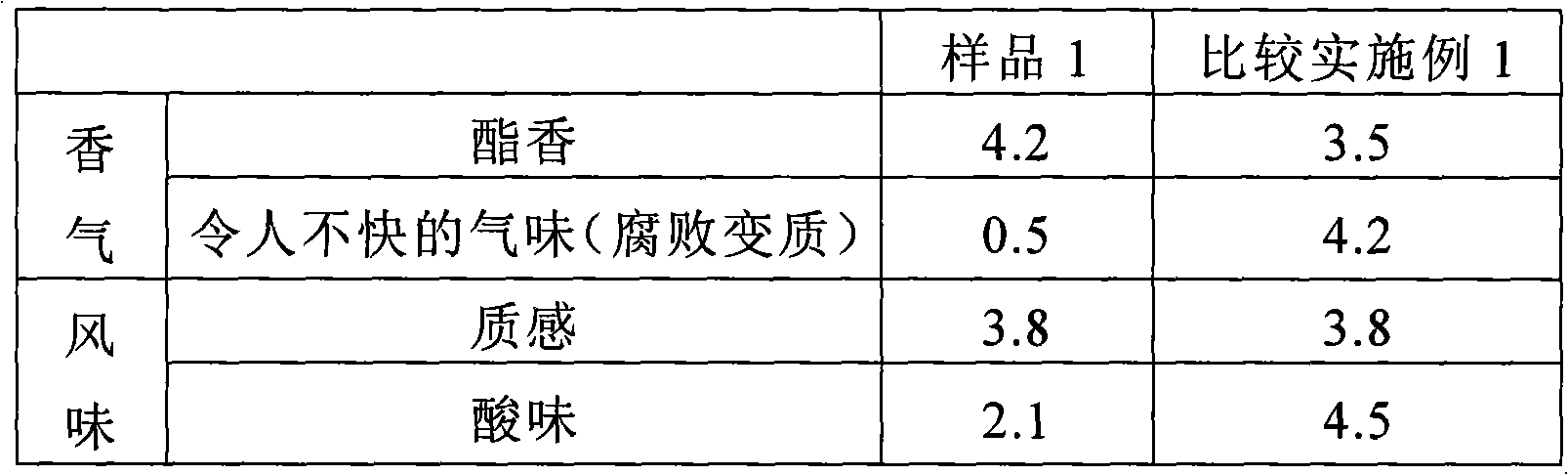

[0132] Example 1 Study on the Effect of Steam Treatment on Fermentation (Effect of Minimizing Miscellaneous Bacteria)

[0133] The effect of steam treatment on fermentation was studied below with coffee cherries. 1000 g of coffee cherries were processed using a conveyor with adjustable speed (2K conveyor belt steamer, manufactured by Kawasaki Co.) and equipped with a tunnel-shaped steam introduction part, the temperature of the steam used was 100° C., and the processing time was 30 seconds bell. 1000 g of steamed coffee cherries were placed in a 3000 ml flask.

[0134] Next, 4 g of sterile water was added to 1 g of dried cells of EC1118 strain, which is a yeast for wine fermentation, to dissolve the cells. The obtained yeast solution was uniformly applied to 1000 g of steam-treated coffee cherries, and left to ferment at 23° C. for 48 hours (sample 1). Coffee cherries that were not steamed were prepared as a control (Comparative Example 1).

[0135]The fermented coffee ch...

Embodiment 2

[0146] Embodiment 2 to the research of steam treatment condition and time

[0147] The coffee cherries were steamed with a pressure vessel (HTS-70 / 160, manufactured by Hisaka Works, LTD.) which was adjustable in temperature and pressure and equipped with steam introducing means.

[0148] The coffee cherries were steamed under the following conditions:

[0149] The steam temperature is 70°C, and the processing time is 60 seconds (sample 2-1);

[0150] The steam temperature is 100°C, and the processing time is 5 seconds (sample 2-2);

[0151] Steam temperature 100°C, treatment time 30 seconds (sample 2-3);

[0152] Steam temperature 100°C, treatment time 300 seconds (sample 2-4);

[0153] Steam temperature 100°C, treatment time 60 minutes (sample 2-5);

[0154] Steam temperature 110°C, treatment time 30 seconds (samples 2-6); and

[0155] Steam temperature 150°C, treatment time 10 seconds (samples 2-7).

[0156] After steam treatment, fermentation was carried out accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com