Metal Sn doped MgB2 superconductor and high-temperature rapid preparation method thereof

A high-temperature, fast, superconductor technology, applied in the field of superconductivity, can solve problems such as easy crystal growth, high crystallinity, and lower critical current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

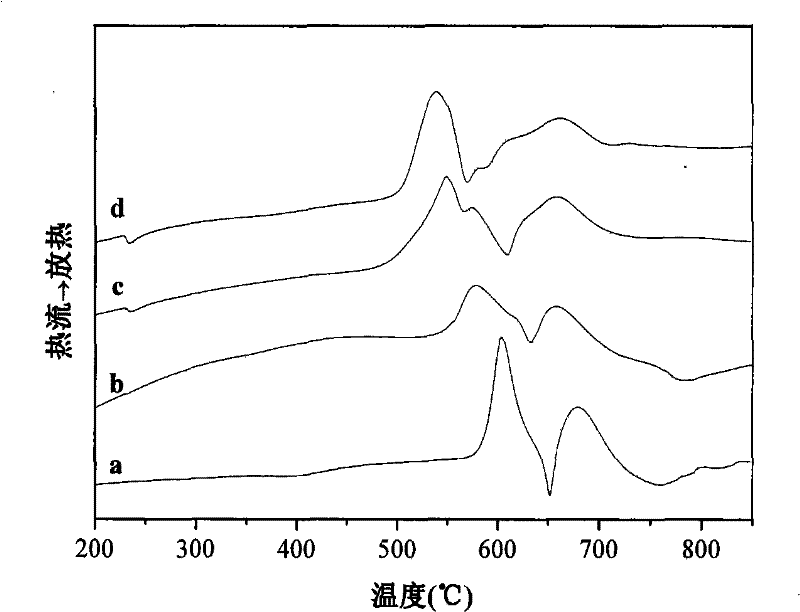

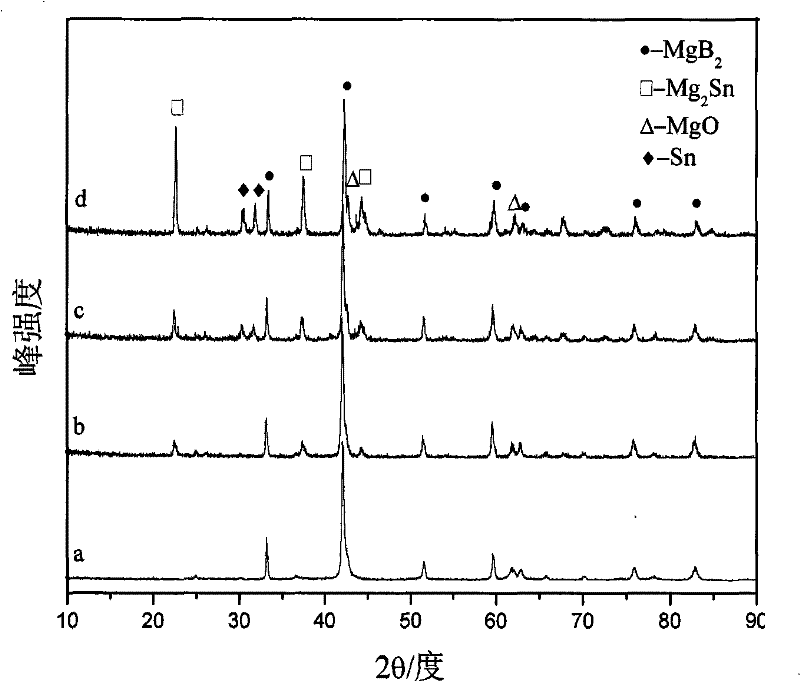

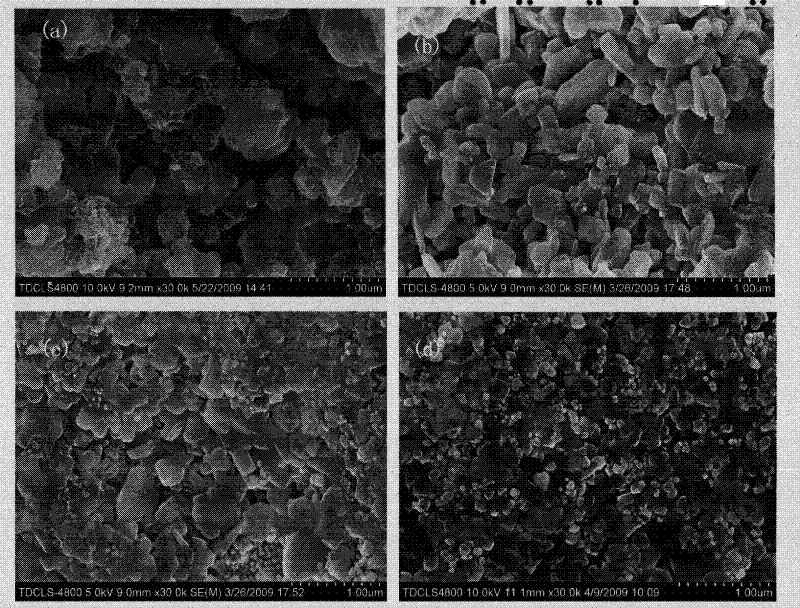

[0025] The Mg powder, B powder and Sn powder are in atomic ratio (Mg 1.02 B 2 ) 0.99 sn 0.01 Mix and grind in an agate mortar for half an hour to mix well. These mixed powders are pressed into cylindrical flakes under a pressure of 2Mpa, and then the pressed samples are placed in a crucible in a high-temperature differential scanning calorimeter, and continuously heated to 850°C at a heating rate of 5°C / min and kept for 0.2 hours The sintering treatment was performed, and then the temperature was lowered to room temperature at a cooling rate of 35° C. / min. It was determined by testing that the sample was composed of MgB 2 , Sn and Mg 2 Sn phase composition (such as figure 2 shown), and MgB 2 The crystals are in good shape (e.g. image 3 shown).

example 2

[0027] The Mg powder, B powder and Sn powder are in atomic ratio (Mg 1.02 B 2 ) 0.97 sn 0.03 Mix and grind in an agate mortar for half an hour to mix well. These mixed powders were pressed into cylindrical flakes under a pressure of 10 MPa, and then the pressed samples were placed in a crucible in a high-temperature differential scanning calorimeter, and continuously heated to 850 °C at a heating rate of 10 °C / min for 0.3 hours. Carry out sintering treatment, and then drop to room temperature at a cooling rate of 30 / min. It was found by physical property measurement (Mg 1.02 B 2 ) 0.97 sn 0.03 The sample has the highest critical current density (such as Figure 4 and 5 shown).

example 3

[0029] The Mg powder, B powder and Sn powder are in atomic ratio (Mg 1.02 B 2 ) 0.95 sn 0.05 Mix and grind in an agate mortar for half an hour to mix well. These mixed powders were pressed into cylindrical flakes under a pressure of 5Mpa, and then the pressed samples were placed in a crucible in a high-temperature differential scanning calorimeter, and continuously heated to 900°C at a heating rate of 20°C / min for 0.4 hours. Carry out sintering treatment, and then drop to room temperature at a cooling rate of 40°C / min. It is determined by detection that the phase in the sample is still composed of MgB 2 , Sn and Mg 2 Sn phase composition (such as figure 2 As shown), it shows that the phase composition does not change much at high temperature, but the high holding temperature at 900°C will lead to grain growth, so it is proved that the (Mg 1.02 B 2 ) 0.95 sn 0.05 The sample can obtain better superconducting performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com