Inorganic dry powder painting

An inorganic dry powder and coating technology, applied in the field of architectural coatings, can solve the problems of uncontrollable color stability, easy to return to alkali, and insufficient durability of inorganic materials, etc., to achieve beautiful texture, reduce cost, and coating shape rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The component and content of the inorganic dry powder coating of the present embodiment are: inorganic binding powder bentonite 10%, mineral sand 55.7%, heavy calcium powder 30%, organic binding rubber powder (FX2350) 4%, methyl cellulose 0.2%, Polypropylene fiber 0.1%.

[0041] Its preparation process is as follows:

[0042] The inorganic dry powder coating is produced by a dry powder mixer, and the powder is produced by a fully automatic electronic control feeding device to ensure the accuracy of feeding.

[0043] Feeding sequence: first put in ore sand and heavy calcium, and then put in inorganic bonding powder, organic rubber powder, cellulose, and polypropylene fiber in sequence.

[0044] The powder is mixed in the mixer for 800-1000 seconds to make the powder evenly mixed, and each batch is sampled to check the uniformity of the powder.

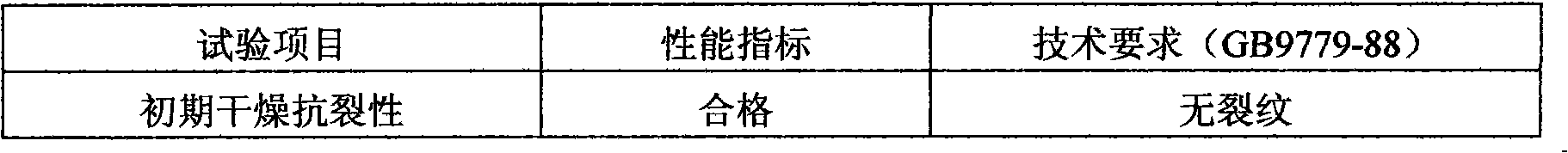

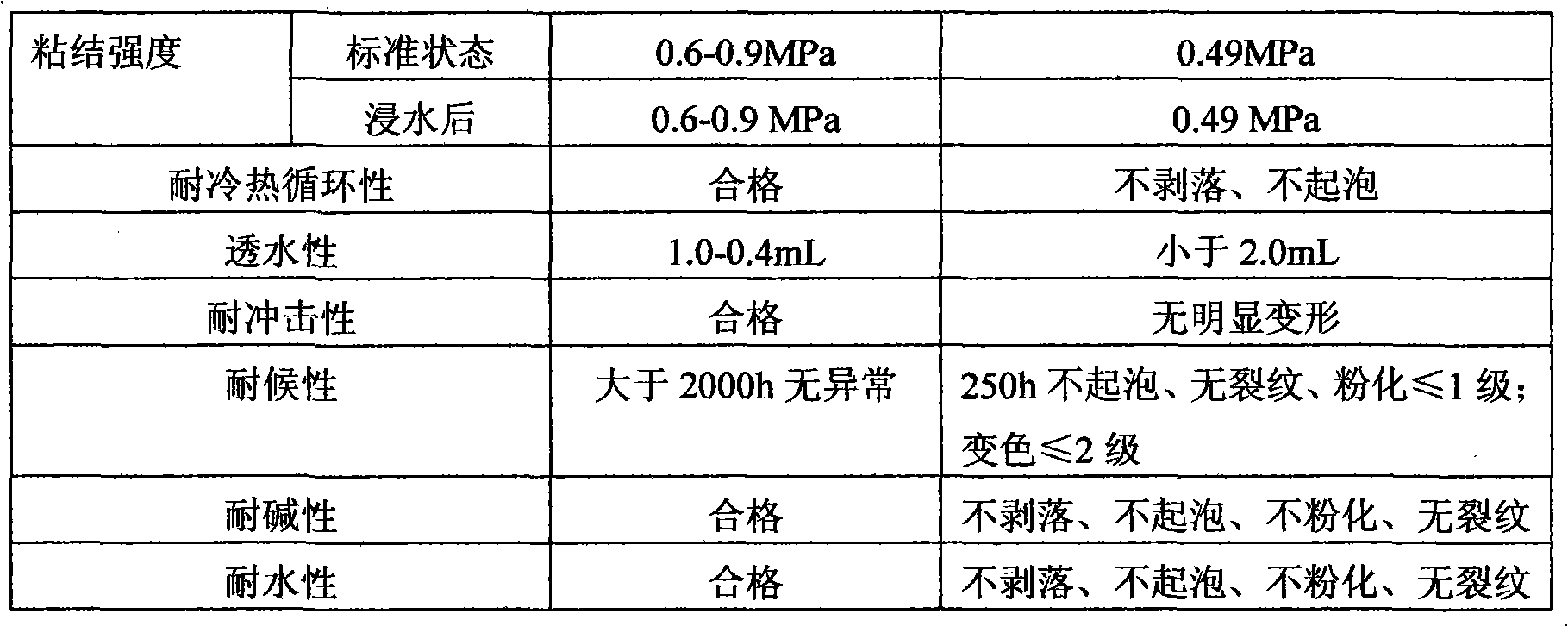

[0045] After inspection, the performance of the inorganic dry powder coating of the present embodiment is as follows:

[004...

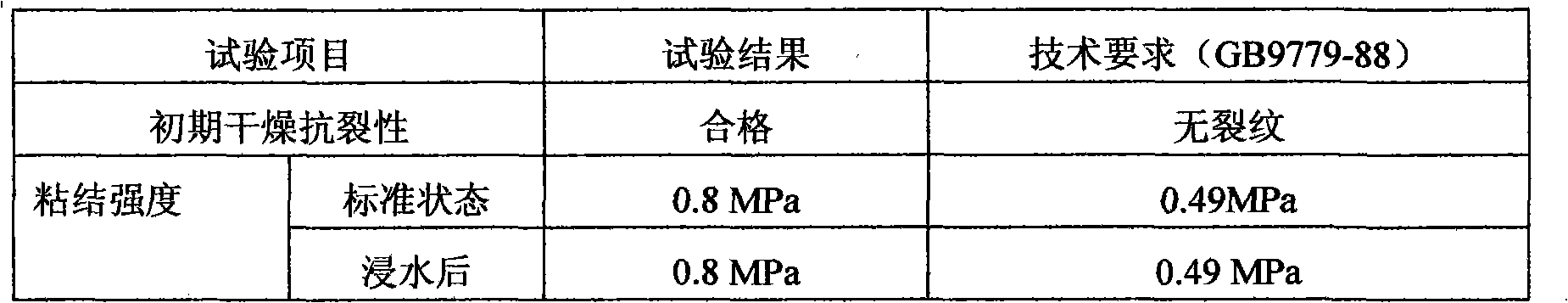

Embodiment 2

[0055] The component and content of the inorganic dry powder coating of present embodiment are: inorganic binding powder 20%, ore sand 50%, heavy calcium powder 24%, organic binding rubber powder (5044) 5%, hydroxyethyl cellulose 0.5%, Polypropylene fiber 0.5%.

Embodiment 3

[0057] The component and content of the inorganic dry powder coating of the present embodiment are: inorganic binding powder 30%, ore sand 30%, heavy calcium powder 30%, organic binding rubber powder (PAV29) 9.5%, hydroxyethyl cellulose 0.3%, Polypropylene fiber 0.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com