Liquid helium heat sink support structure for reducing experimental cost

A technology of supporting structure and heat sink, which is applied in the testing of machine/structural components, engine testing, measuring devices, etc., can solve the problems such as the increase of additional test cost and the increase of liquid helium consumption, to increase the effective test space, The effect of less liquid consumption and reduction of the amount of liquid helium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

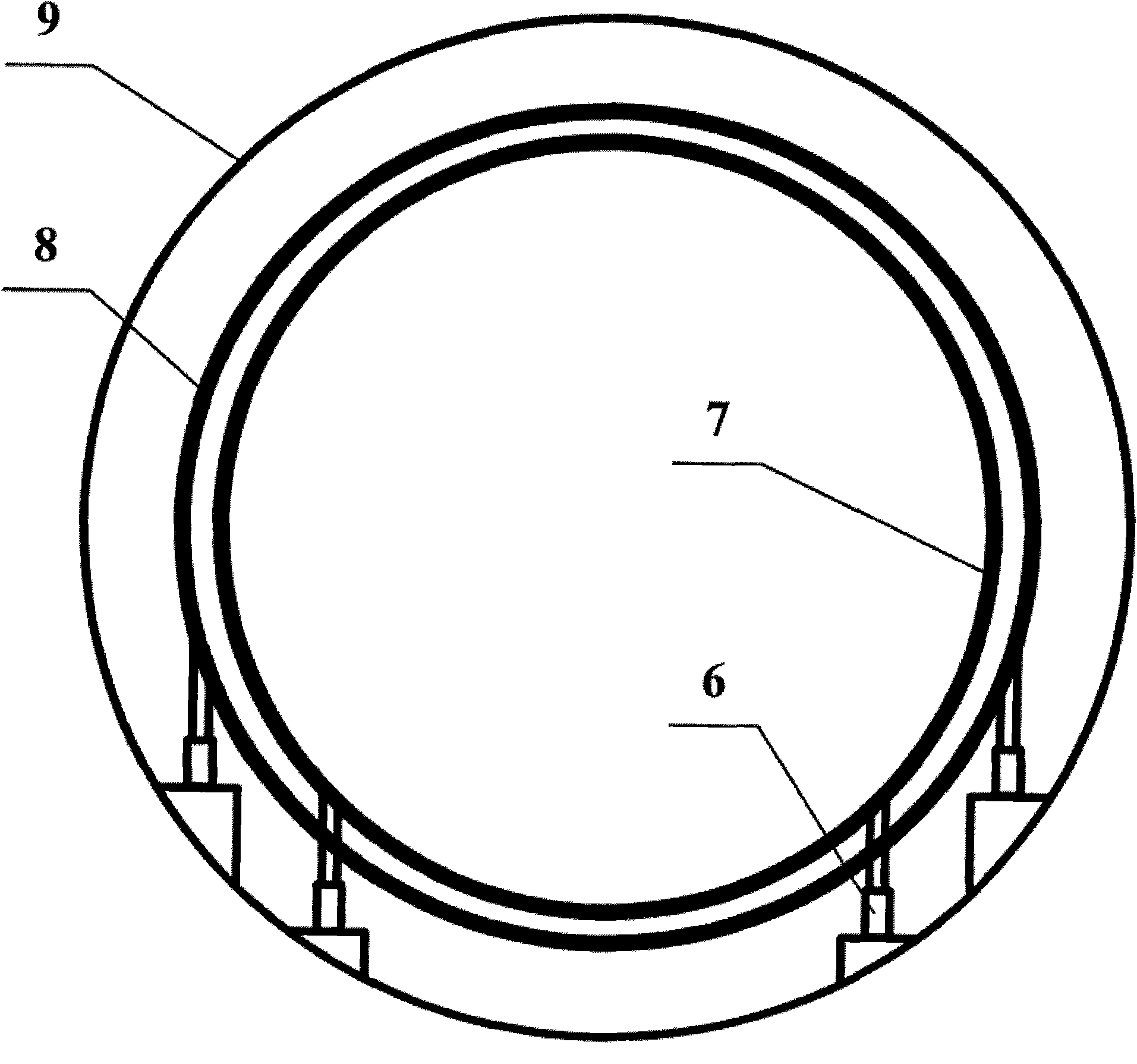

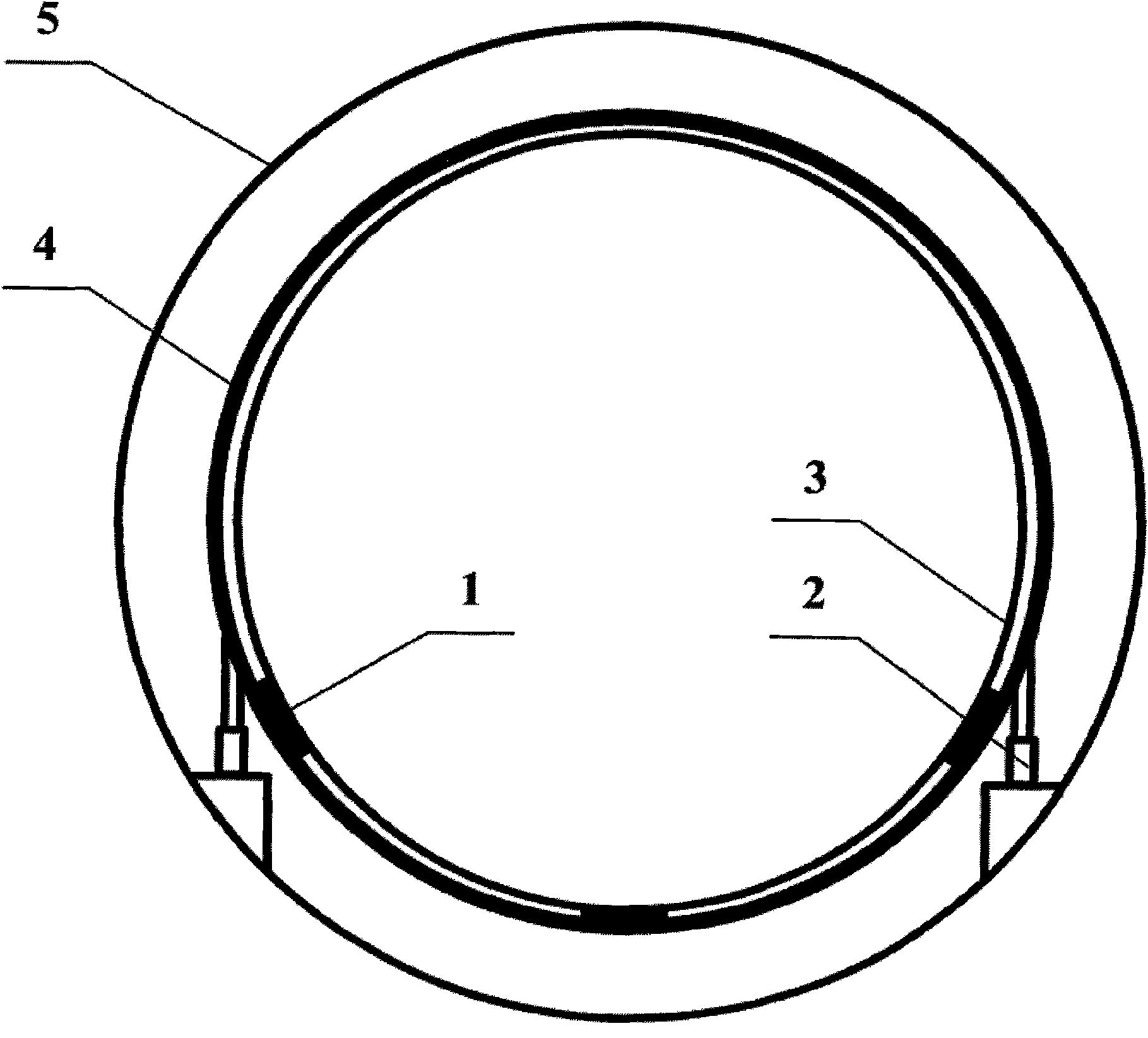

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] 1. Analysis of pre-cooling process of liquid helium heat sink

[0013] In order to reduce the consumption of liquid helium, during pre-cooling, first fill liquid nitrogen into the liquid helium heat sink pipeline to fully pre-cool the liquid helium heat sink to 100K, and then use liquid helium to continue to pre-cool the liquid helium heat sink until the liquid helium heat sink When the temperature of the helium heat sink reaches about 10K, the test is started.

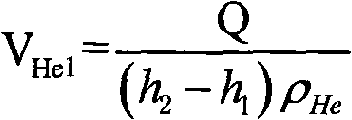

[0014] During the pre-cooling process, the total liquid helium consumption formula is as follows:

[0015] V He =V He1 +V He2

[0016] V He 1 = Q ( h 2 - h ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com