Method for modeling and virtually assembling five-axle number control machine tool based on UG

A technology of CNC machine tools and virtual assembly, applied in simulators, program control, computer control, etc., can solve the problems of high manufacturing cost and complex rotating structure, and achieve the effect of improving manufacturing efficiency and reducing manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

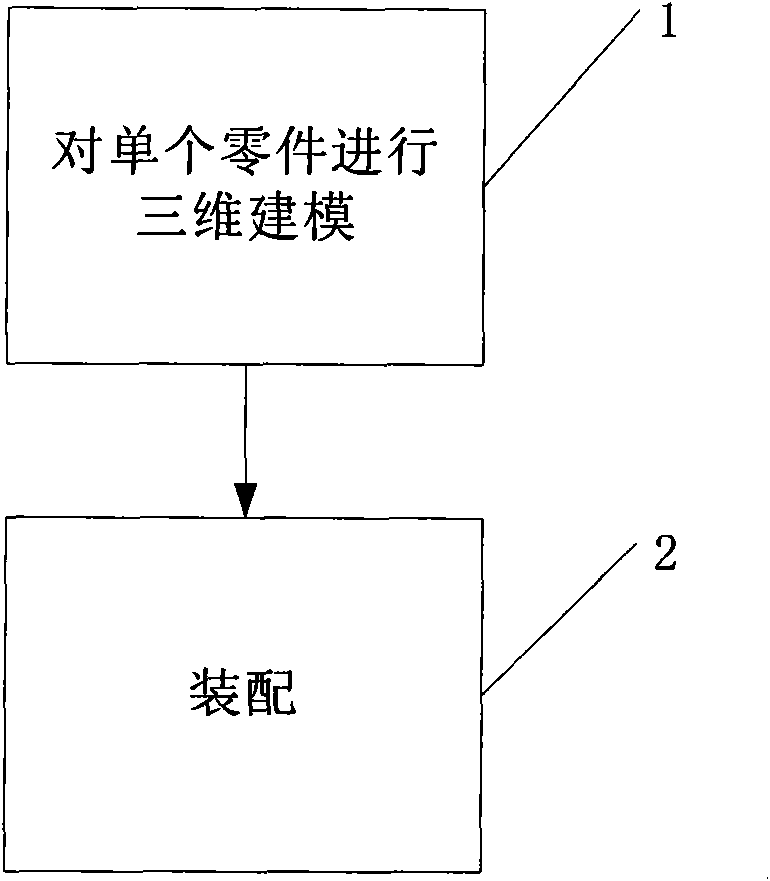

[0025] see figure 1 , the figure shows the UG-based five-axis CNC machine tool modeling and virtual assembly method of the present invention, in the present embodiment, using UG NX4.0 software, the present invention includes the following steps:

[0026] Step 1 of three-dimensional modeling of a single part is to draw a three-dimensional figure according to the actual size of the part of the five-axis CNC machine tool. This step includes the self-made parts modeling step and the standard parts modeling step, wherein:

[0027] The self-made component modeling steps are used for modeling based on the UG platform, through display modeling, parametric modeling and constraint-based modeling. The combination of these three modeling methods is composite modeling. Features are:

[0028] (1) Provide more flexibility in the design process.

[0029] (2) Establish a fully correlated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com