Thermal management device and method for making the same

A heat control and heat source technology, applied in chemical instruments and methods, manufacturing tools, lamination devices, etc., can solve problems such as increased difficulty, poor thermal conductivity, high thermal resistance, etc., to reduce manufacturing costs and time, improve thermal performance, Effect of reducing thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

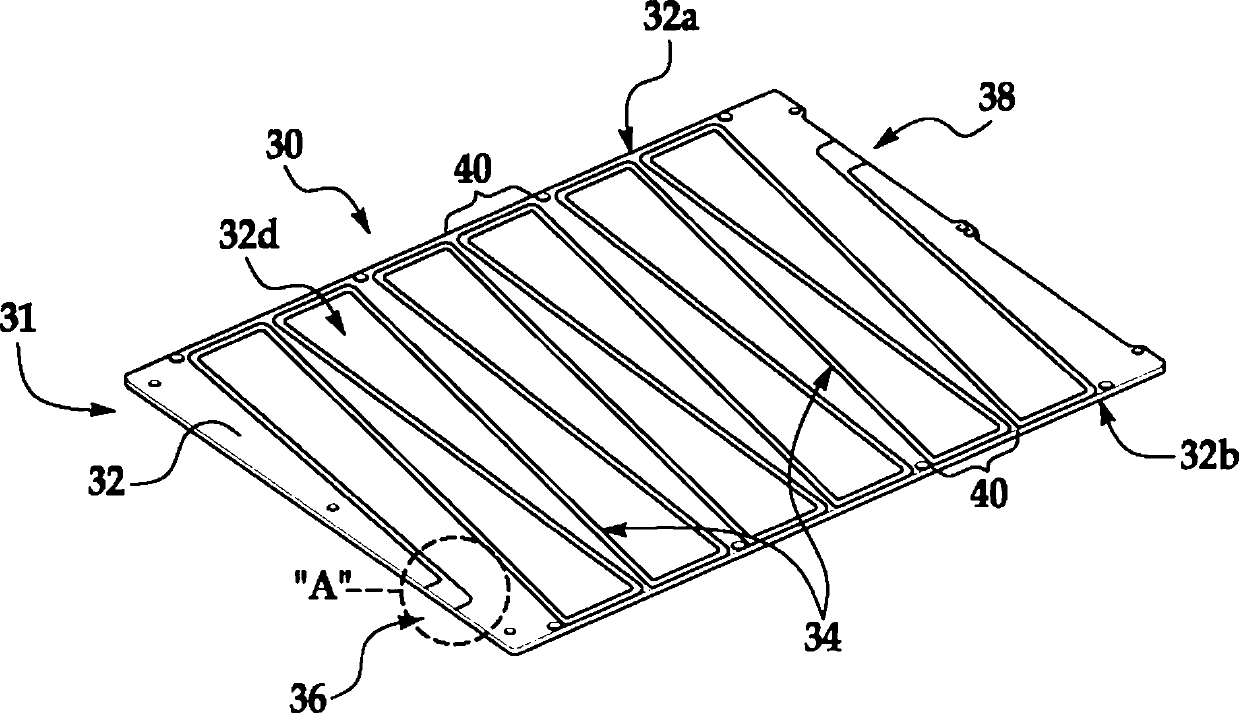

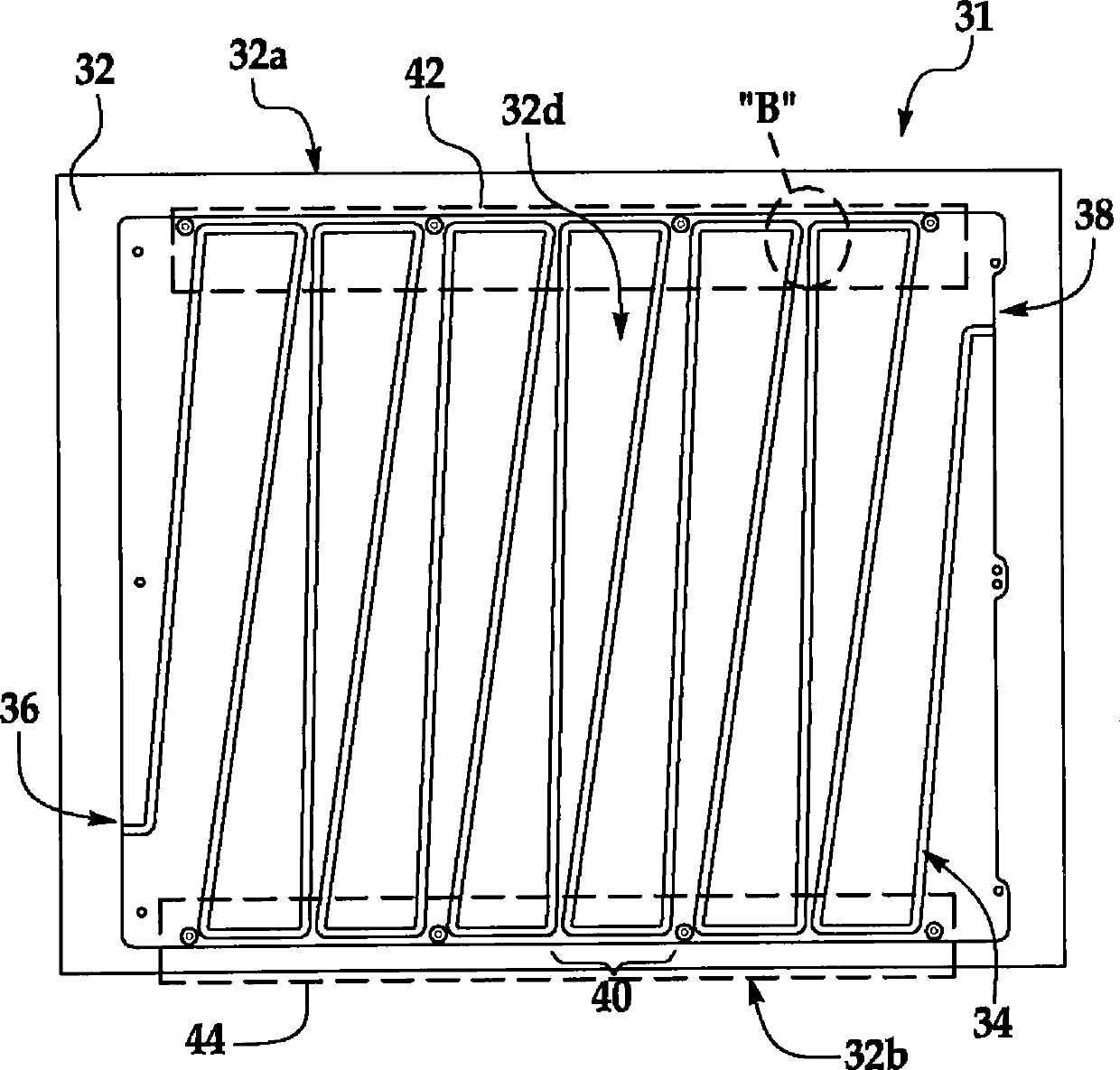

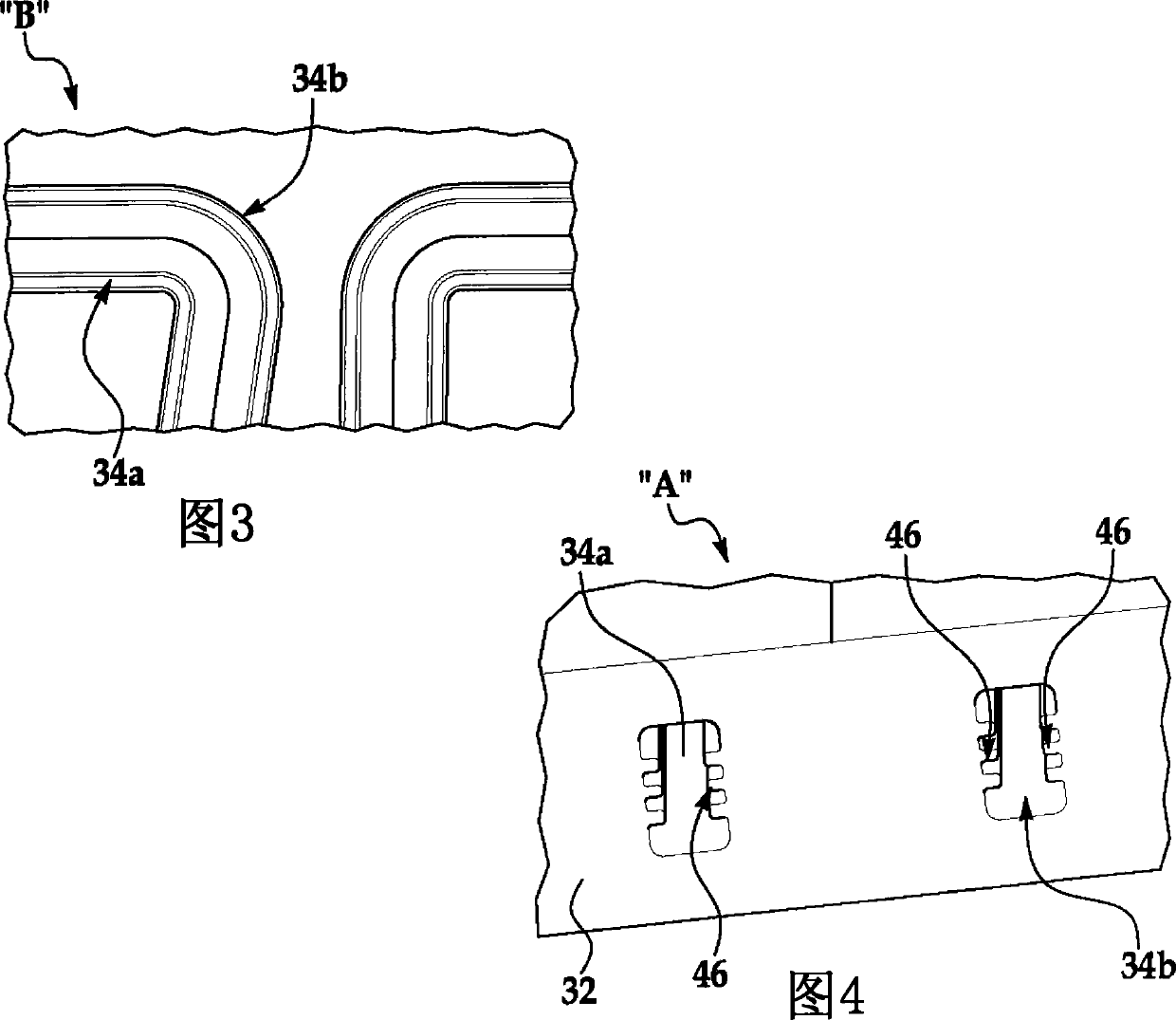

[0077] first reference Figure 1-8 , the disclosed embodiments generally relate to a thermal control device 30 comprising a monolithic (monolithic, monocoque) body 32 having an internal inset channel 34 . exist Figure 1-8 In the depicted embodiment, the monolithic body 32 comprises a generally rectangular plate that, as will be discussed below, can be used as a chassis 32c (see Figure 13 ), the chassis 32c has broad surfaces 32d, 32e on which heat generating elements (not shown) can be mounted. The monolithic body 32 may be formed from a thermally conductive material using a consolidation or similar process to be discussed later, in which successive layers of material are fused to form a monolithic, one-piece body 32 in which the channel 34 is connected to the body 32. Overall shape. By way of example and not limitation, body 32 may comprise an alloy consisting of one or more of aluminum, copper, manganese, nickel, gold, silver, and titanium.

[0078] exist Figure 1-8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com