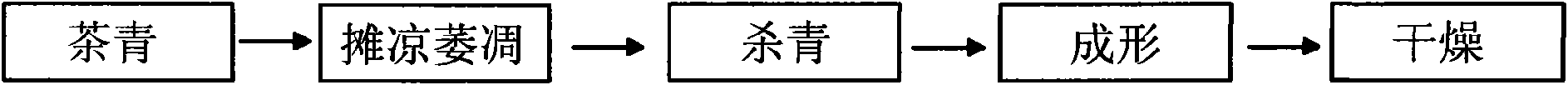

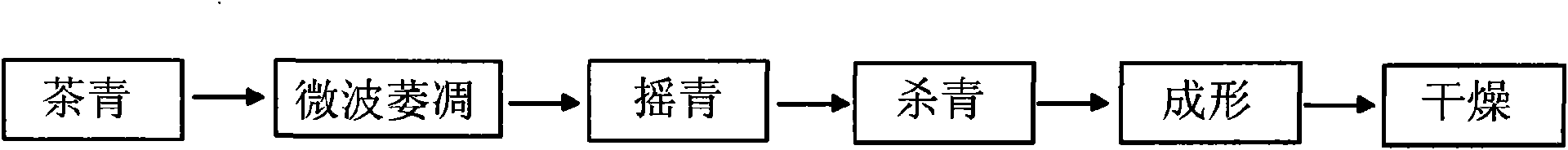

New process and special device for microwave withering and rocking of fresh green tea leaves in green tea processing

A special equipment and new process technology, which is applied in the field of microwave withering of fresh leaves and new technology of shaking green tea in green tea processing, can solve the problems of water loss, red leaf color change, and reduced picking amount, so as to improve the processing efficiency and make the tea soup yellow and green. The effect of brightening and reducing the warehouse area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

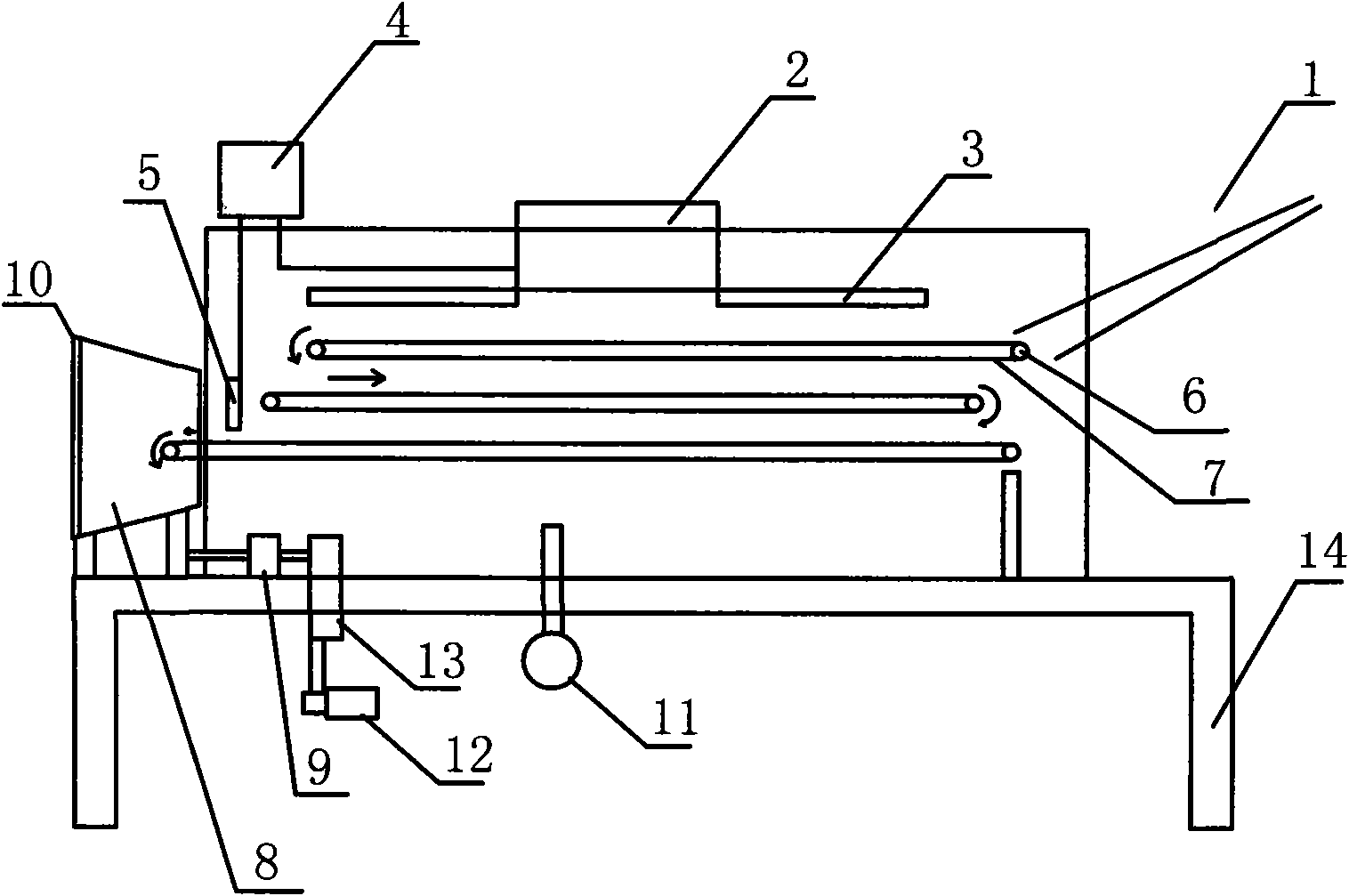

[0009] The new technology and special equipment of microwave withering and shaking of fresh leaves in green tea processing of the present invention, combined with the accompanying drawings, will describe the embodiment of the present invention in detail, and use the special equipment microwave heater to wither fresh tea leaves, so that the fresh tea leaves lose part of their water. part, complete the withering process, and then send the dark green tea that has reached a certain degree of withering into the next section of the greening process or shaking green process. The edges of the tea leaves have certain frictional damage, and the enzyme activity in the damaged area is strengthened, which increases the special fragrance of the tea when brewing. The degree of shaking green tea varies with different varieties of green tea. Time, so that it meets the process requirements of different grades and varieties of green tea for control. For example, if the finished tea leaves are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com