Cloth bag frame with dust collecting bag capable of being popped automatically

An automatic pop-up, bag holder technology, applied in suction filters and other directions, can solve the problems of scattering, excessive force of paper bags, shaking, etc., and achieve the effect of high support strength and high-end quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be described in detail below with reference to the drawings and examples.

[0067] In the drawings of the present invention, the same components as those in the prior art use the same symbols.

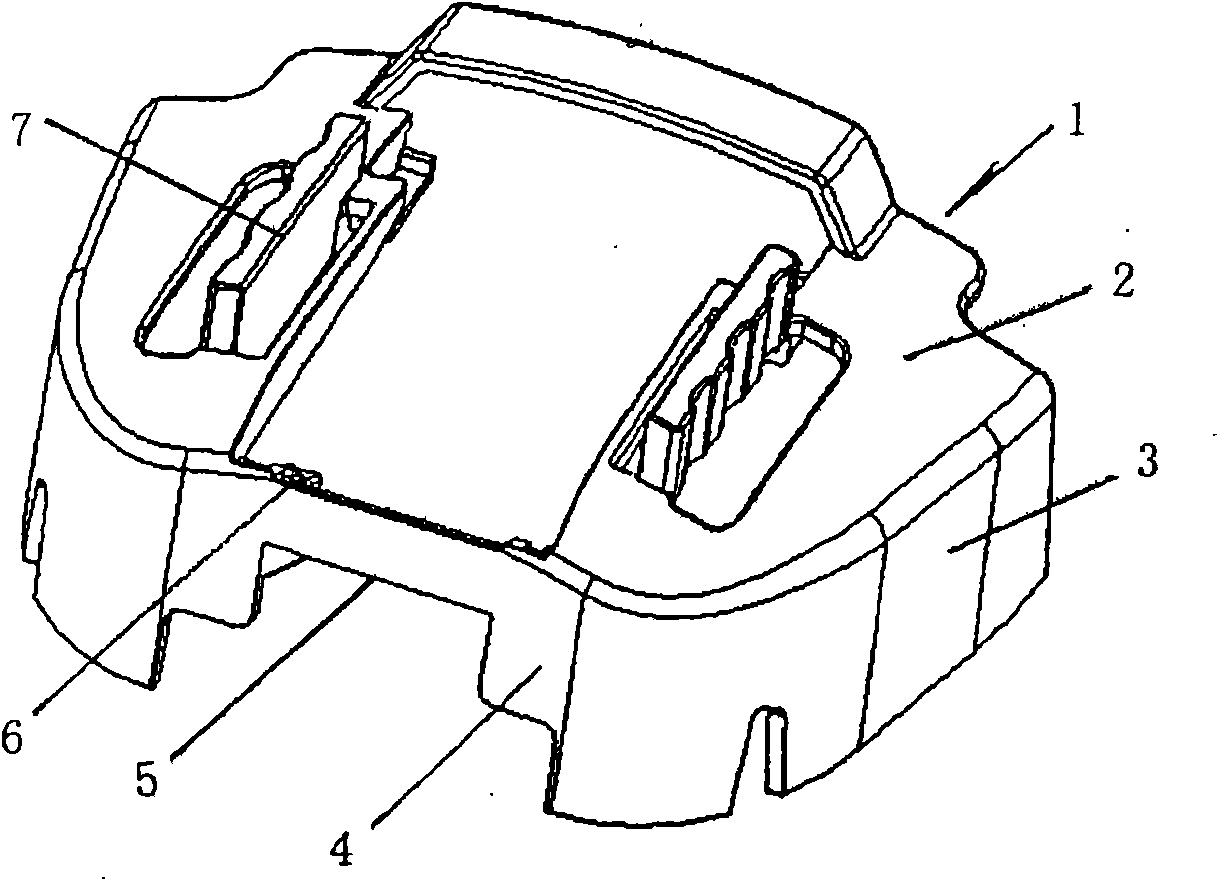

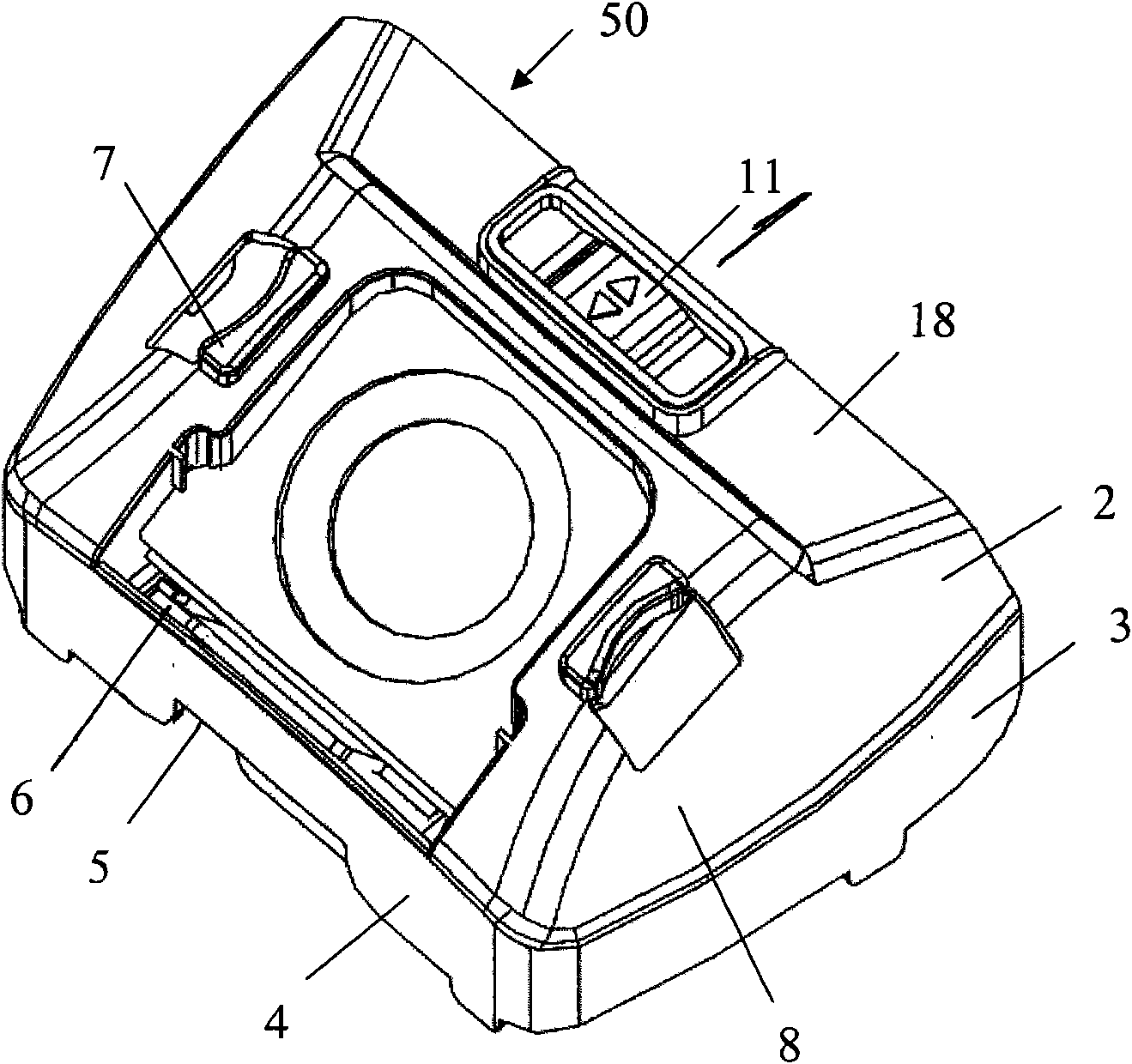

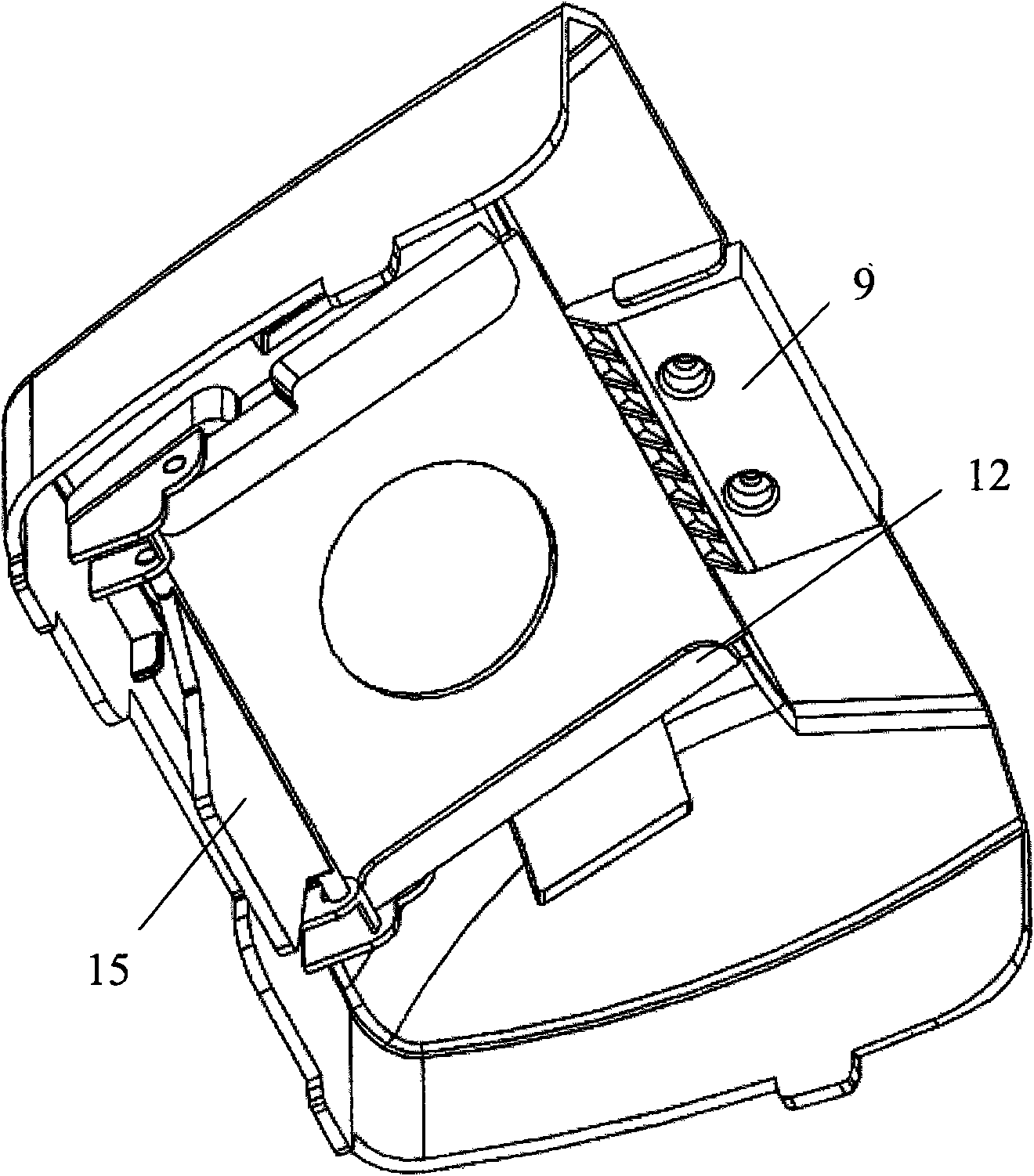

[0068] The cloth bag frame 50 that the dust bag of the present invention pops up automatically, such as figure 2 , image 3 , Figure 4 as shown,

[0069] figure 2 It is a three-dimensional view of the bag frame structure of the present invention; image 3 It is a three-dimensional view of the back structure of the bag rack of the present invention; Figure 4 It is an exploded view of the bag frame structure of the present invention.

[0070] The cloth bag rack 50 that the dust bag of the present invention pops up automatically includes: a side panel 3 extending downwards connected with both sides and the front end of the panel 2, a front panel 4, and a stepped opening 5 on the front panel. On the inner side of the dashboard, a housing 8 consist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com