Self-feeding control device of mineral crusher

An automatic feeding and crusher technology, applied in grain processing and other directions, can solve problems such as inability to perform signal feedback, equipment and work restrictions, and achieve the effects of avoiding overload operation, rapid crushing, and uniform feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

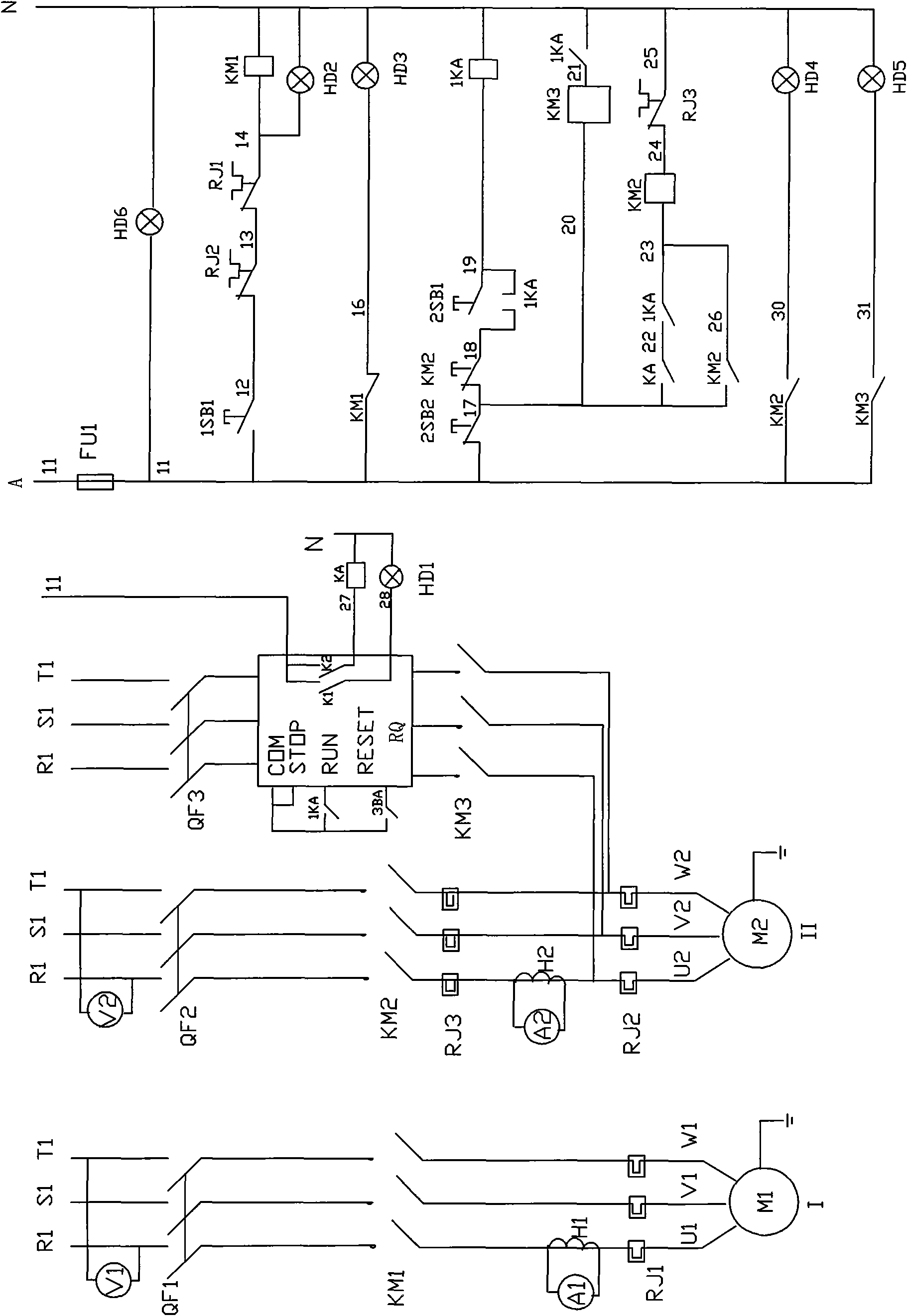

[0016] The invention integrates the relationship between the two power systems of the crusher and the feeder, and fully avoids the occurrence of the phenomenon that the crusher is overloaded due to too fast feeding of the feeder, thereby damaging the structural parts of the crusher. In order to realize the effective synergy between feeding and crushing in the ore crushing process, so that the feeding is uniform, the crushing is rapid, and the production is continuous. The relay RJ3 is to protect the limit current value of the crusher motor M2, and an overcurrent relay RJ2 is added to control the highest current value generated by the crusher motor M2, thereby controlling the start and stop of the feeder motor M1.

[0017] The mineral crusher automatic feeding control device of the present invention, such as figure 1 , figure 2 As shown, it include...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap