Full-automatic bottle blowing machine

A bottle blowing machine, fully automatic technology, applied to other household appliances, household appliances, applications, etc., can solve the problems of poor heating effect, large space occupation, and large machine volume, so as to improve work efficiency and stability , the effect of high-efficiency embryo management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

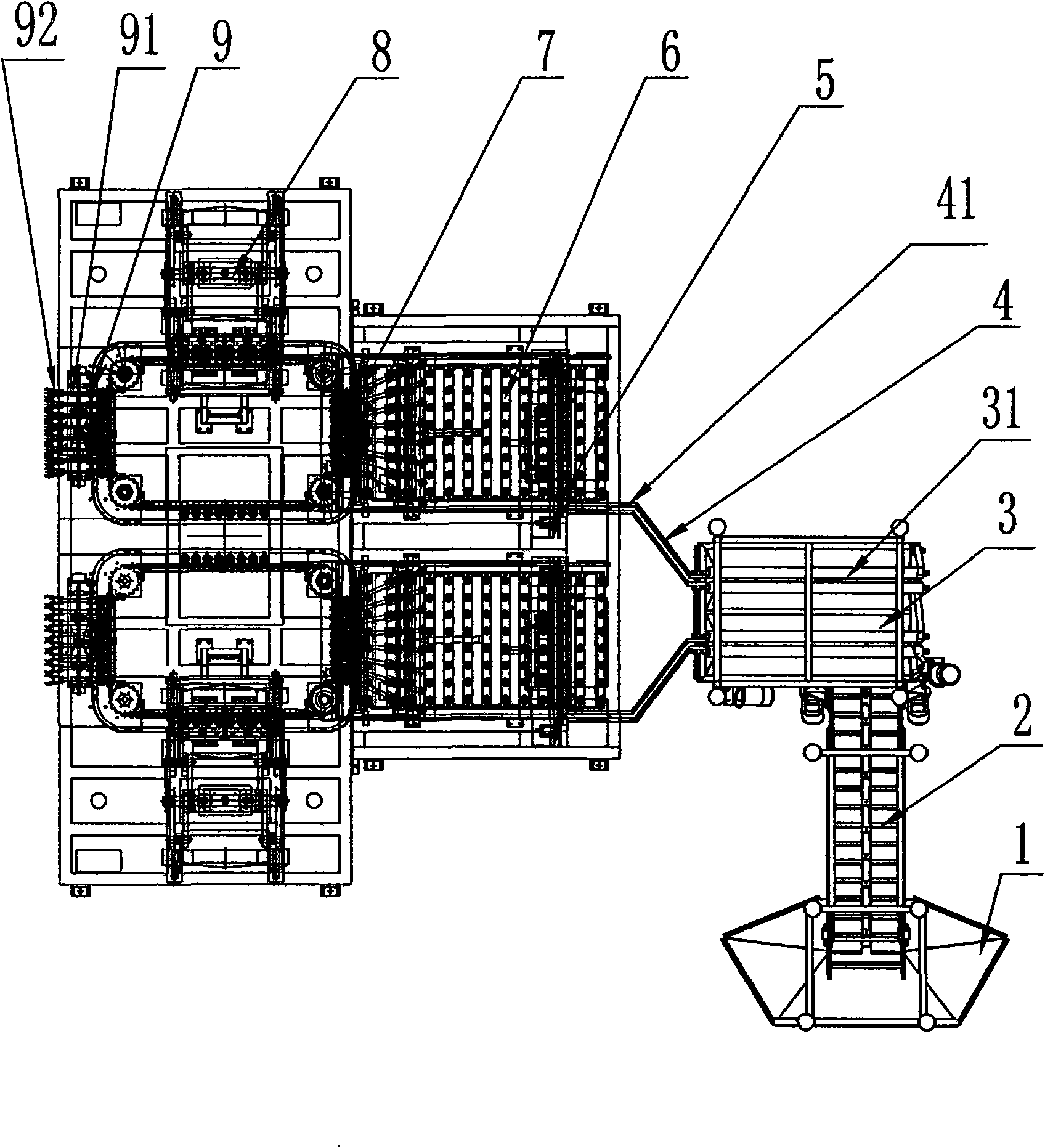

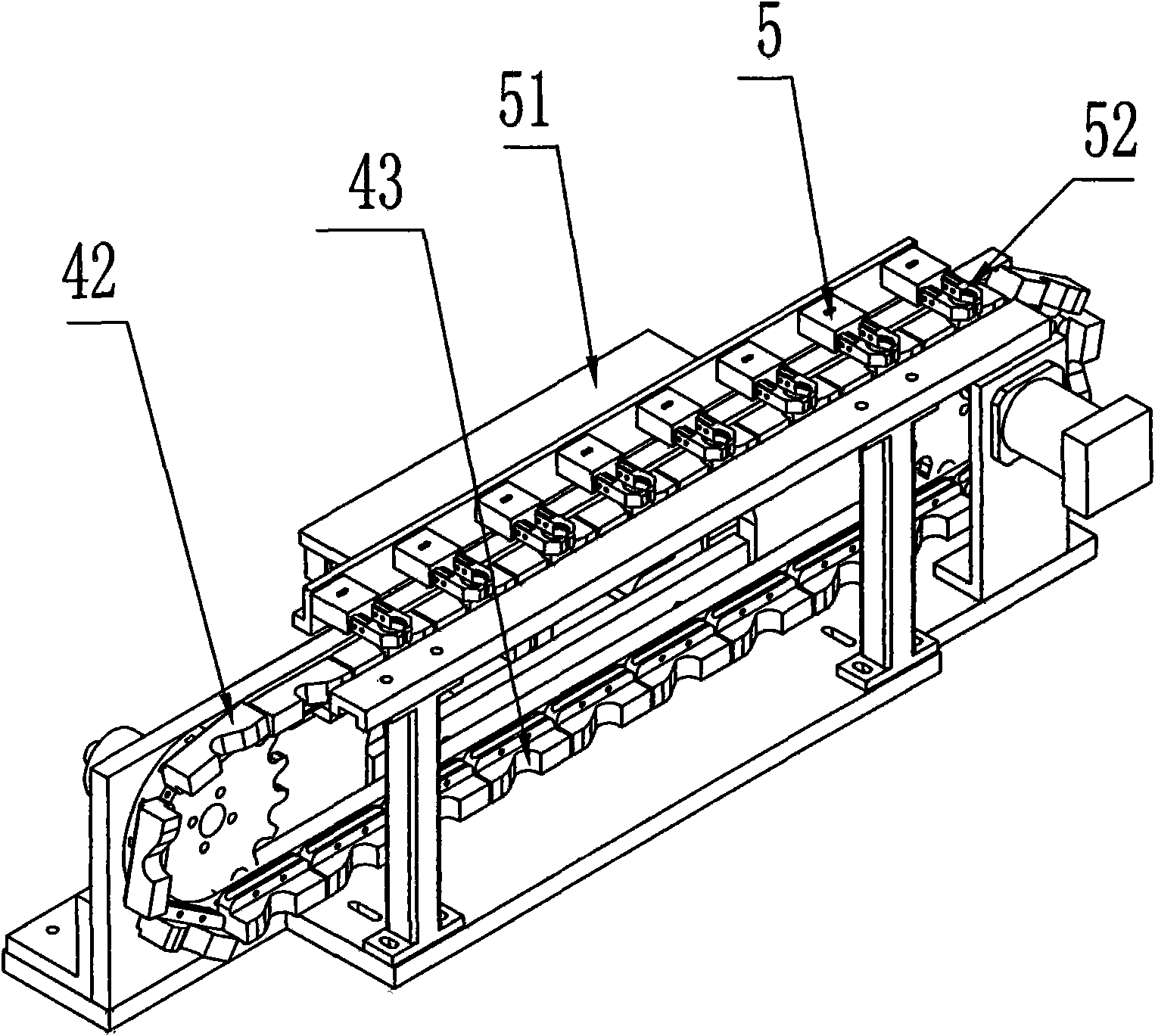

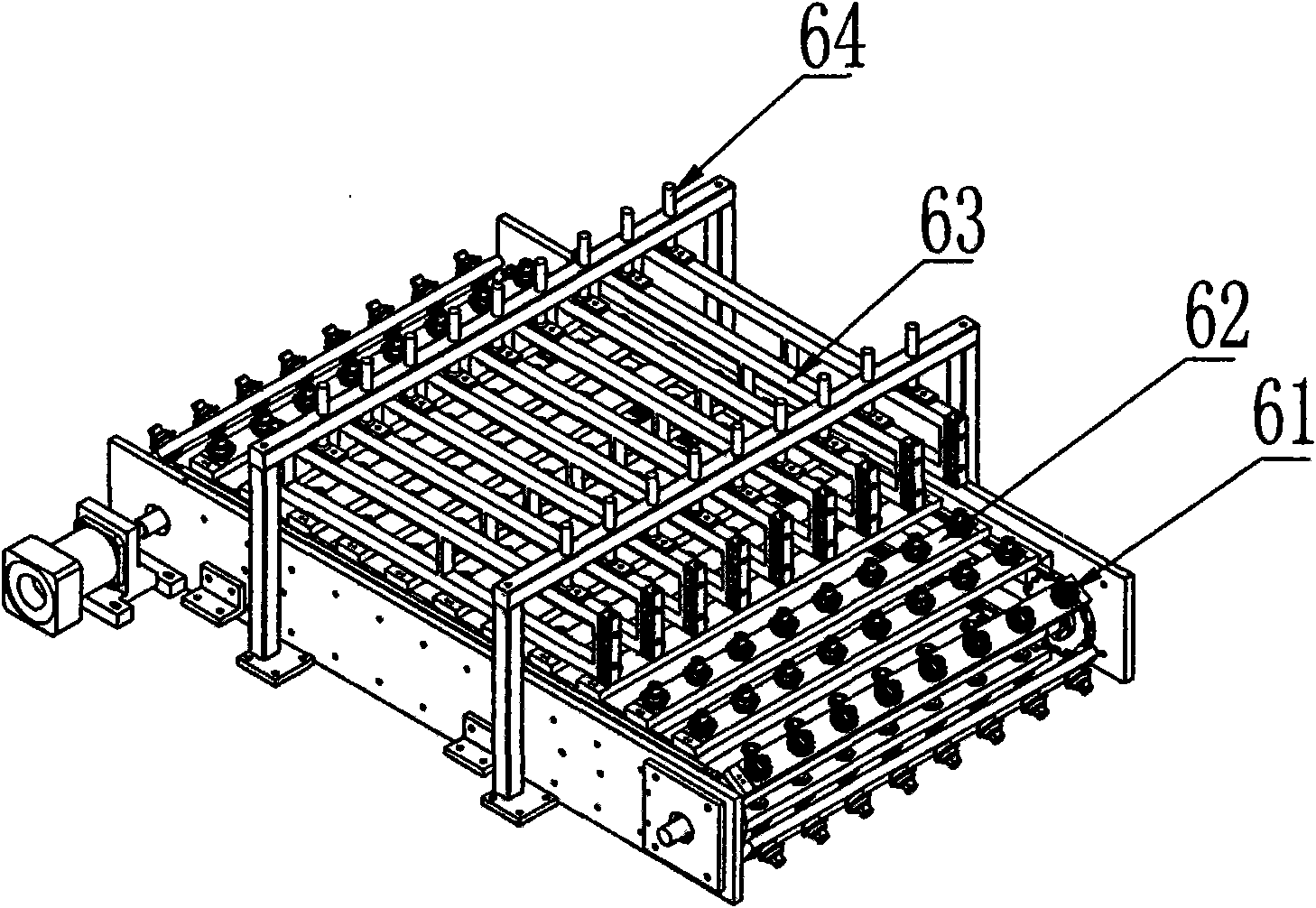

[0021] refer to figure 1 , including a feed hopper 1, the discharge port of the feed hopper 1 is equipped with a lifting mechanism 2, and the lifting mechanism 2 is provided with a double alignment mechanism 3 that can regulate the preforms, and the double alignment mechanism 3 discharges The end is equipped with a double preform mechanism 4 that sends the preform to the bottom of the two sets of preform manipulators 5 and waits for the preform manipulators 5 to be picked up. A heating system 6 is installed above each set of preform manipulators 5. The heating system The discharge end of 6 is provided with a lane-changing manipulator 7 that sends the preform to an automatic synchronous stretch blow system 8, and an automatic bottle discharge manipulator 9 is installed on the other side of the automatic synchronous stretch blow system 8.

[0022] The double alignment mechanism 3 includes two sets of alignment shafts 31 arranged in parallel.

[0023] The double blank unscrambli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com