Array multithreaded electromagnetic sucker hanger mechanism

An electromagnetic chuck, multi-head technology, applied in the direction of load hanging components, transportation and packaging, can solve the problems of not having multi-point adsorption and multi-point selective adsorption functions, and unable to meet the requirements of upper and lower steel plates of large CNC steel plate cutting machines. Avoid burning cables, simple and reliable structure, convenient operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

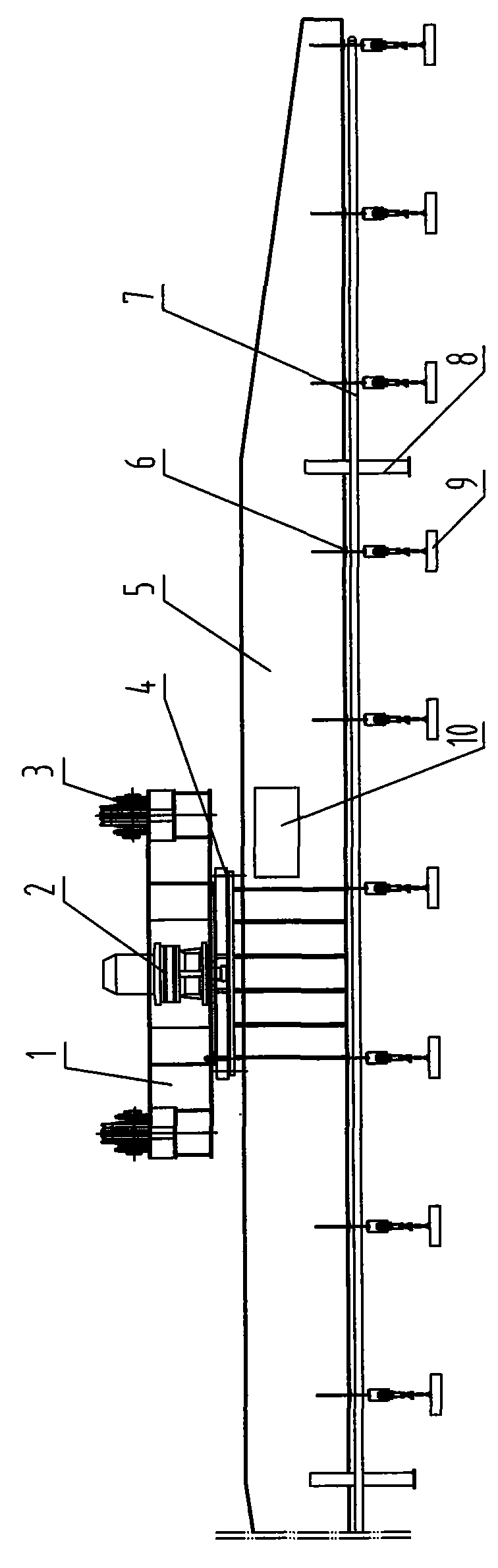

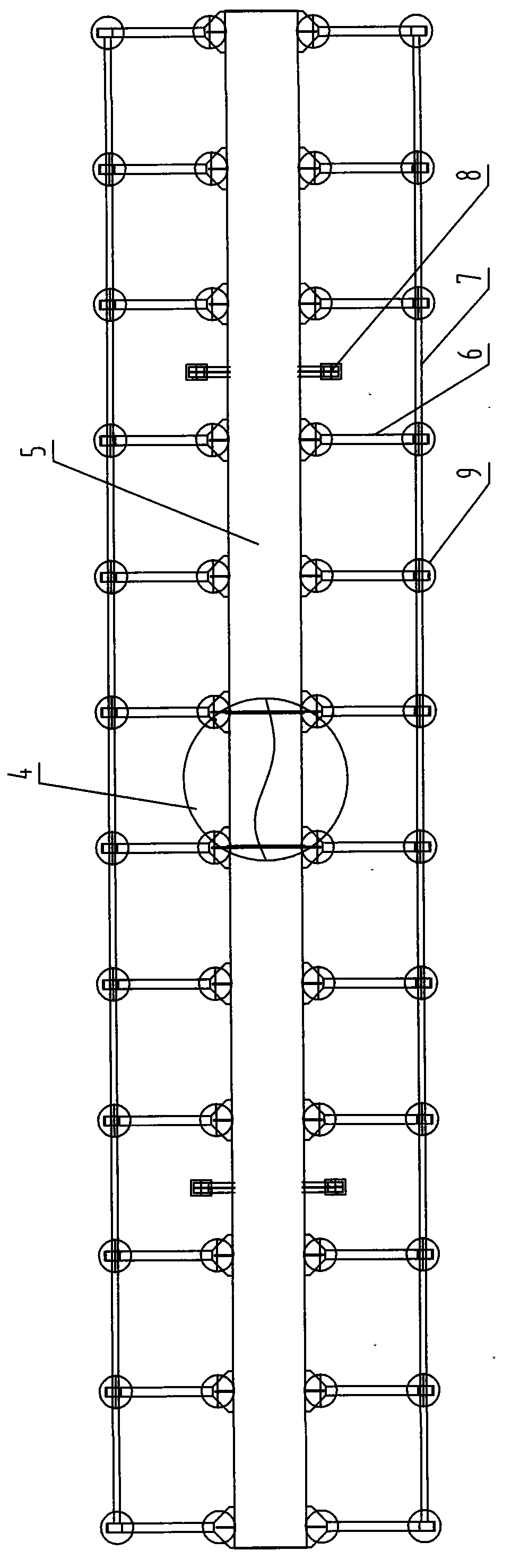

[0016] The present invention selects a certain number (this case is 48) of circular small diameter (this case φ350) electromagnetic suckers 9 to be arranged in an array (this case 4 * 12), and realizes large-area (this case is 3.2m * 14.8m) multi-point adsorption and multi- Click to select the snap function.

[0017] In the present invention, four pulley blocks 3 fixed on the slewing hanger 1 are connected with the hoisting wire rope of the crane; The slewing bearing 4 drives the hanging beam 5 to rotate ±180°; a plurality of small beams 6 are vertically arranged with the hanging beam 5, and each small beam 6 is equipped with an electromagnetic sucker 9 to form an array; the outer ends of the small beams 6 are connected by a support rod 7 to form Integral frame; Hanger is pressed on the electromagnetic sucker 9 when preventing from falling, and supporting leg 8 is housed on the suspension beam 5. An electromagnetic chuck control panel is installed in the driver's cab. The dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com