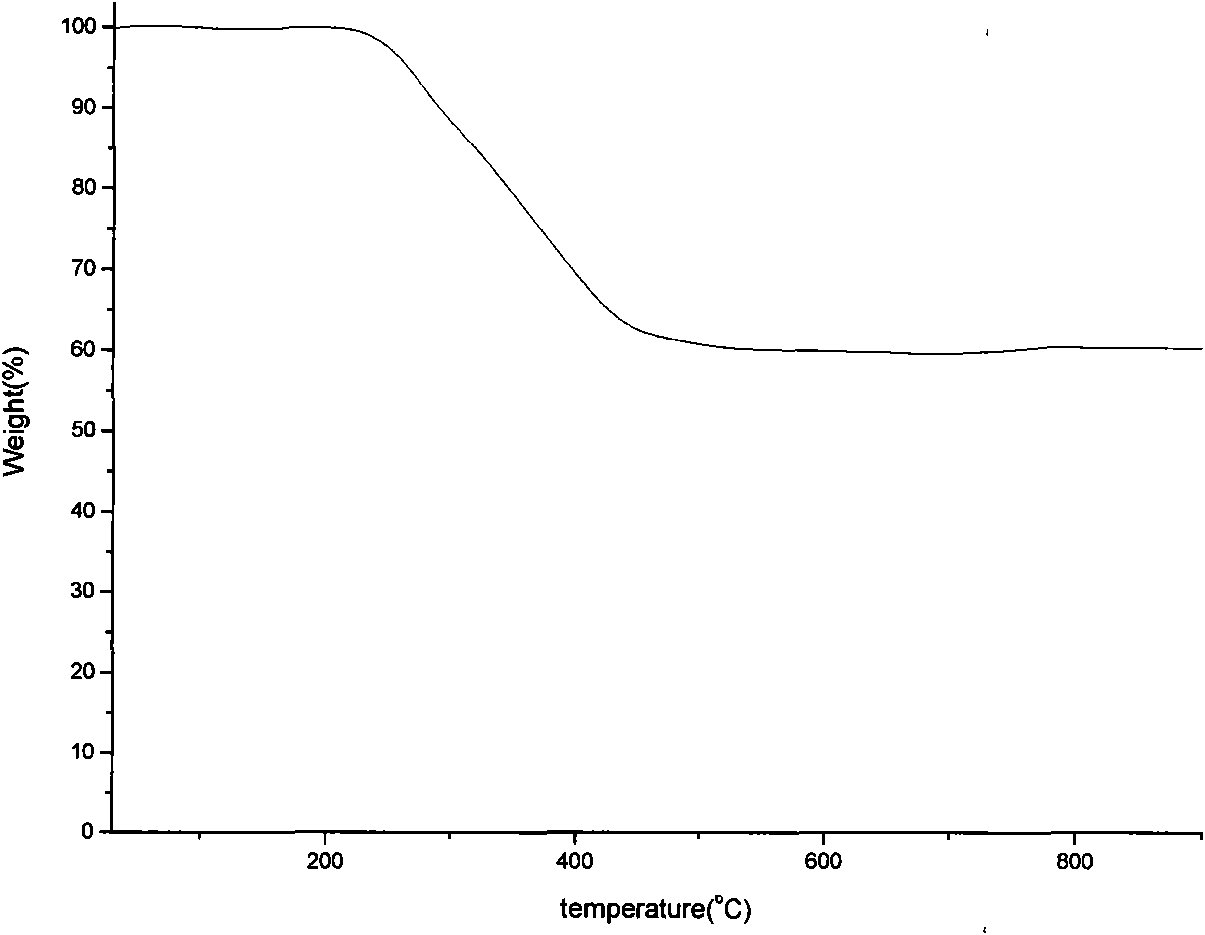

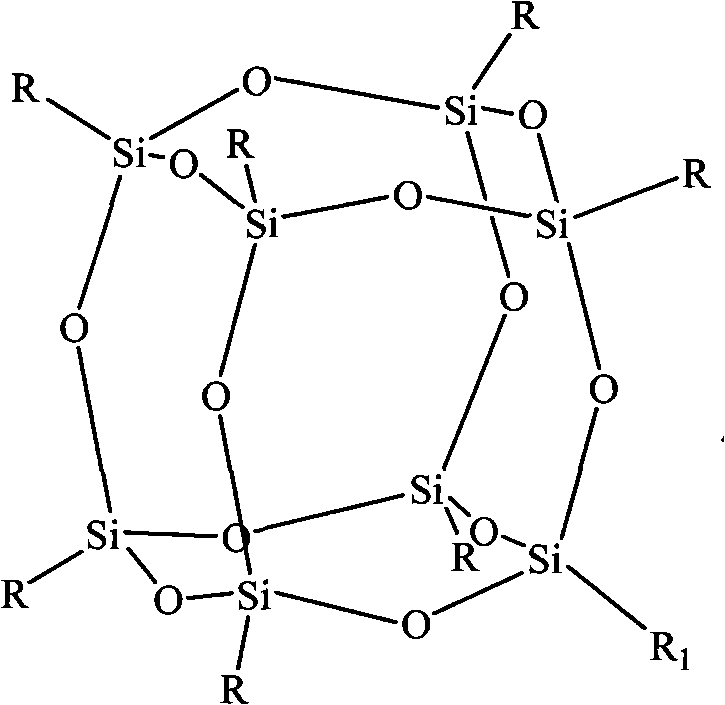

Preparation method of modified ultra-thin fire-resistant coating polymer matrix based on silsesquioxane

A technology of fire-resistant coatings and polymers, applied in the direction of fire-resistant coatings, epoxy resin coatings, coatings, etc., can solve the problems of no flame-retardant mechanism, toxic and harmful gases, research, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1. Mix 0.1phr of octaphenyl POSS and 1phr of phenolic resin matrix in a high-speed disperser for 1 hour, and add other additives according to the preparation method of conventional fireproof coatings.

Embodiment 2

[0030] Step 1. Mix 0.2phr of epoxy-based POSS and 1phr of epoxy resin matrix in a high-speed disperser for 6 hours, and add other additives according to the preparation method of conventional fireproof coatings.

Embodiment 3

[0032] Step 1. Mix 0.1phr of reactive silicon hydrogen based POSS and 1phr of acrylic resin in the reaction kettle evenly.

[0033] Step 2, adding 0.002phr of chloroplatinic acid catalyst, and reacting at room temperature for 5h. Add other additives according to the preparation method of conventional fireproof coatings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com