Test method and device for simulating the circulating enrichment discipline of alkali metal in blast furnace

An alkali metal and alkali metal carbonate technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems such as inability to perform at will, lack of reliability, etc., and achieve high experimental reliability, simple methods, and high simulation reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

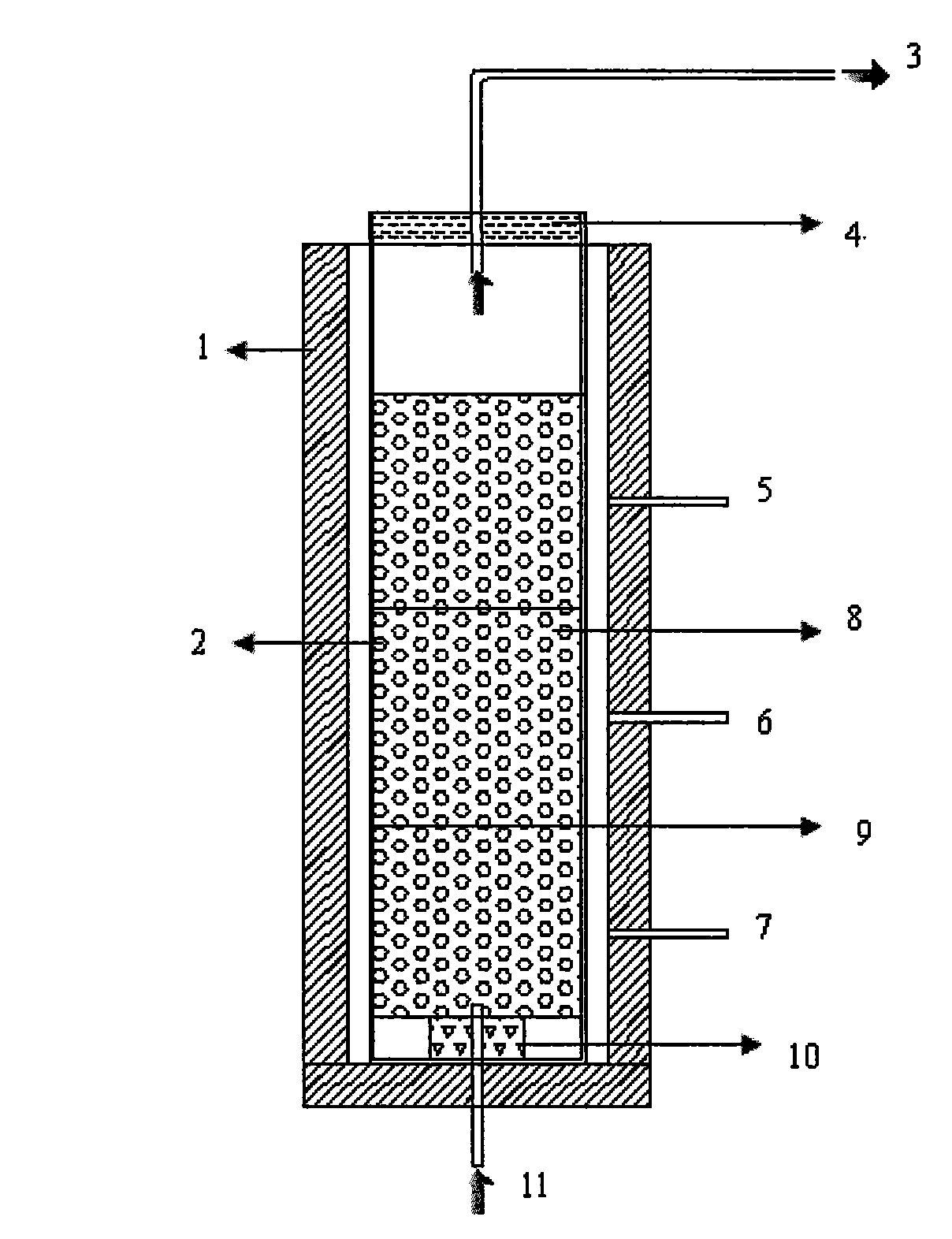

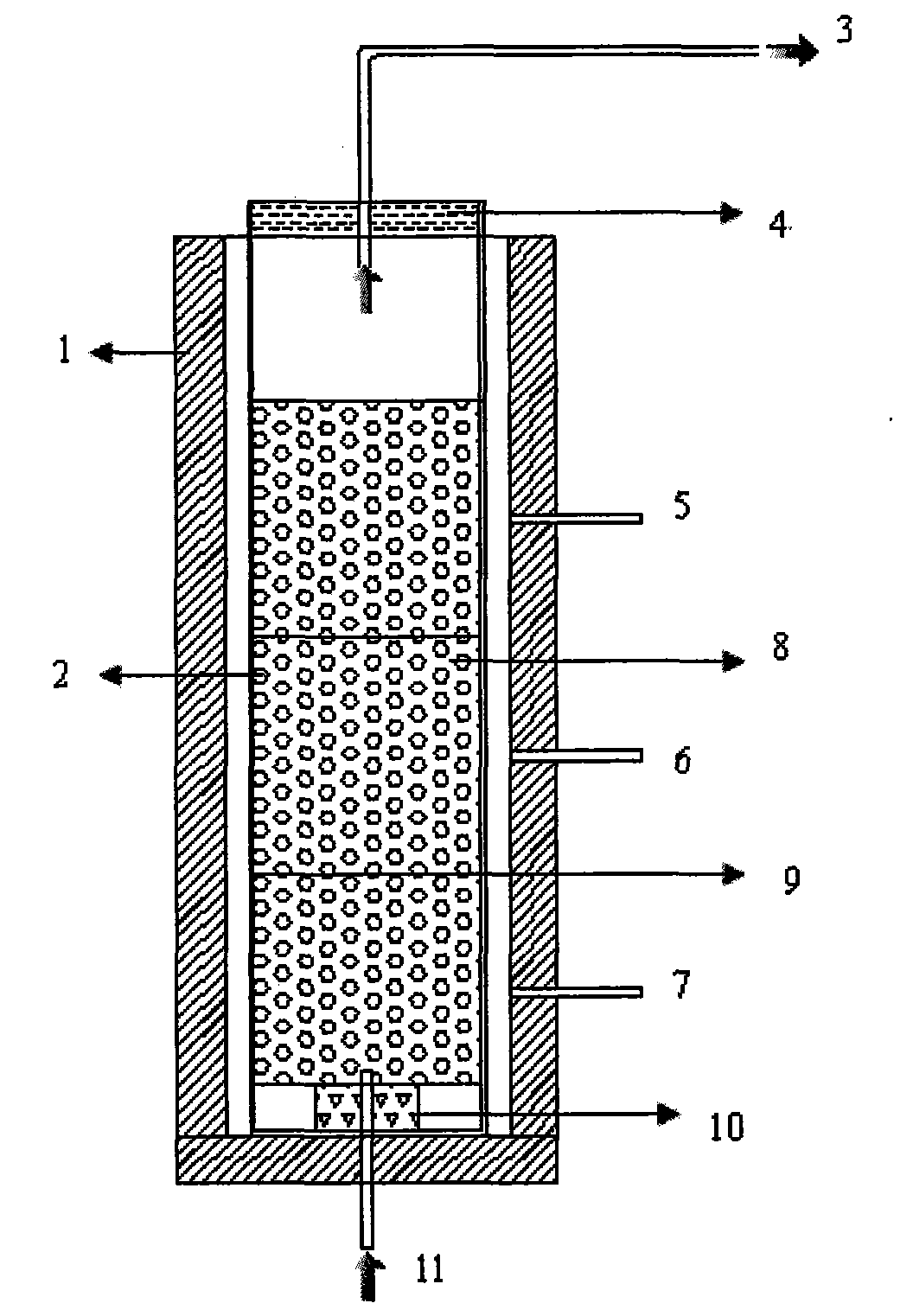

[0018] Embodiment: determine alkali metal amount according to alkali metal load calculation and enrichment degree, this example is the K of 2g 2 CO 3 and 1g of Na 2 CO 3 . According to the needs of the test, add pellets: sintered ore = 3:7, a total of 1000g, add it to the stainless steel crucible, separate the different temperature zones with a mesh screen, and cover the crucible with a threaded buckle after installation .

[0019] Raise the temperature at a heating rate of 8°C / min, pass gas after the temperature reaches 500°C, and keep the reaction for 3 hours. After the reaction is over, start to turn off the power supply of the heating furnace, and with the cooling of the furnace, the temperature of each section is lowered to below 500°C, and the gas flow is stopped. When the temperature of the crucible drops to room temperature, take out the crucible, open the crucible cover and take out the charge.

[0020] Samples were sent for chemical composition and XRD physical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com