Built-in micro-particle type tuning and friction energy dissipation damper

A technology of dampers and granules, which can be applied in building components and anti-seismic, etc., can solve the problems of high cost of tuning system and unfavorable wide application, etc., and achieve the effects of low cost, reduced vibration, and reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

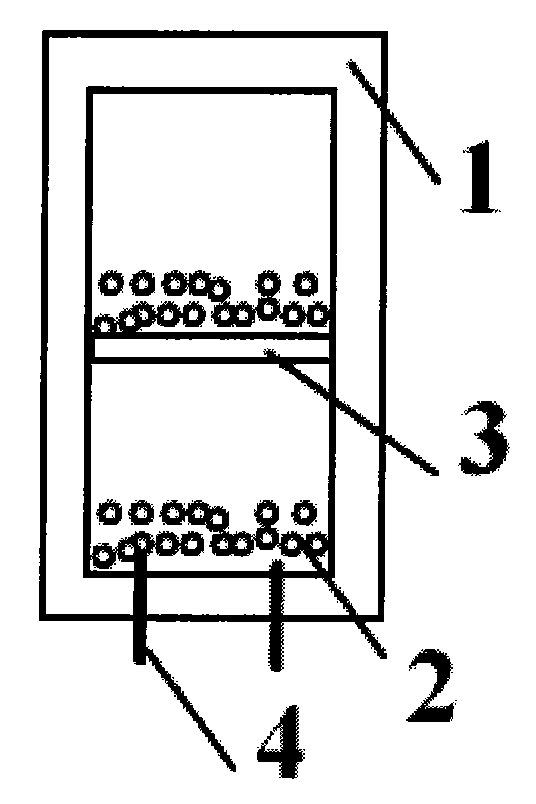

[0025] Such as figure 2 As shown, it is an embodiment of a built-in particle type tuning and frictional collision energy dissipation damper of the present invention, which mainly includes a box body 1, a damping particle group 2 placed in the box body, a partition inside the box body 3, and a connecting member 4 The original beam member 5 of the structure connected with the box body 1.

[0026] The box body 1 is poured with high-strength concrete, and the connection member 4 formed by high-strength bolts is riveted with one side of the original beam member 5 . The box body 1 is generally arranged symmetrically on both sides of the original beam member 5 of the structure. The internal partition 3 of the box is a flat steel plate with a thickness of 6mm, which divides the box 1 evenly into two parts along the beam height direction, such as ...

Embodiment 2

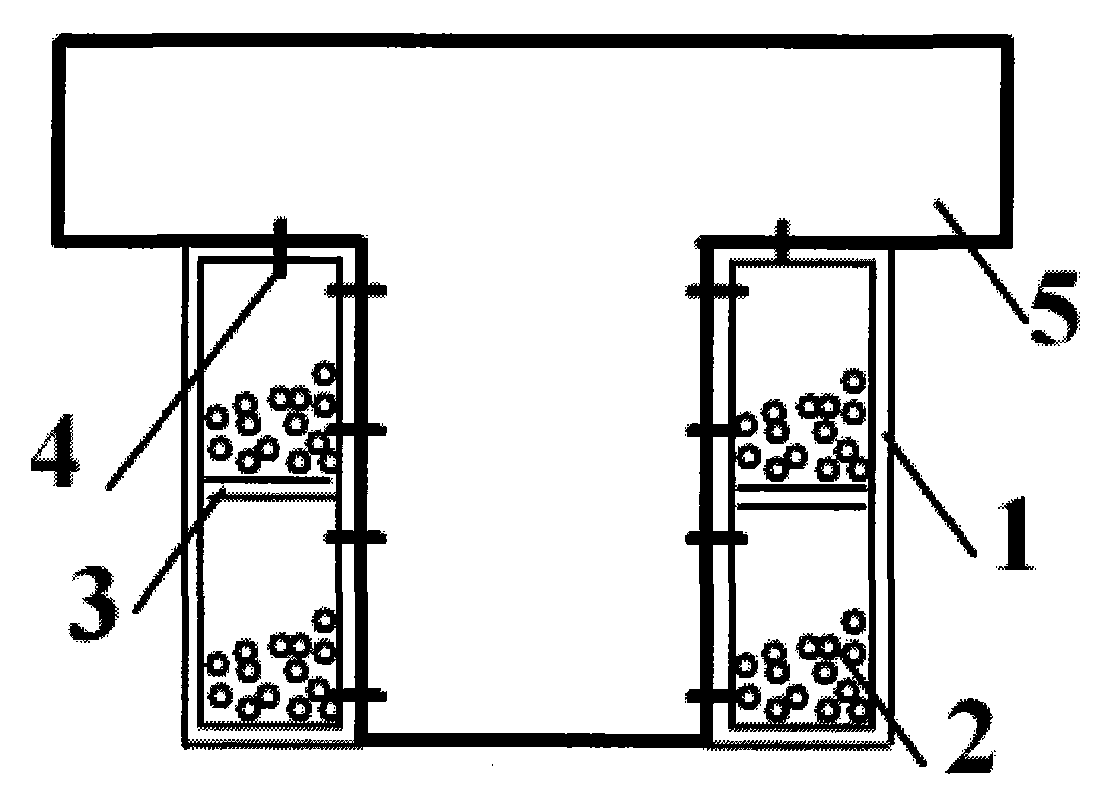

[0029] Such as image 3 As shown, this embodiment mainly includes a box body 1, a damping particle group 2 placed in the box body, a partition plate 3 inside the box body, a connecting member 4 and an original structural column member 6 connected with the box body 1 .

[0030] The box body 1 is poured with high-strength concrete, and the connection member 4 formed by high-strength bolts is riveted with one side of the original column member 6 of the structure. The box body 1 is generally arranged symmetrically on the four sides of the original column member 6 of the structure. The internal partition 3 of the box is a flat steel plate with a thickness of 6 mm, which divides the box 1 into four parts evenly along the direction of column height, such as image 3 shown. The damping particle group 2 is placed in the space composed of the box body 1, the internal partition 3 and the original column member 6 of the structure. The specific material is ceramsite sand with an average ...

Embodiment 3

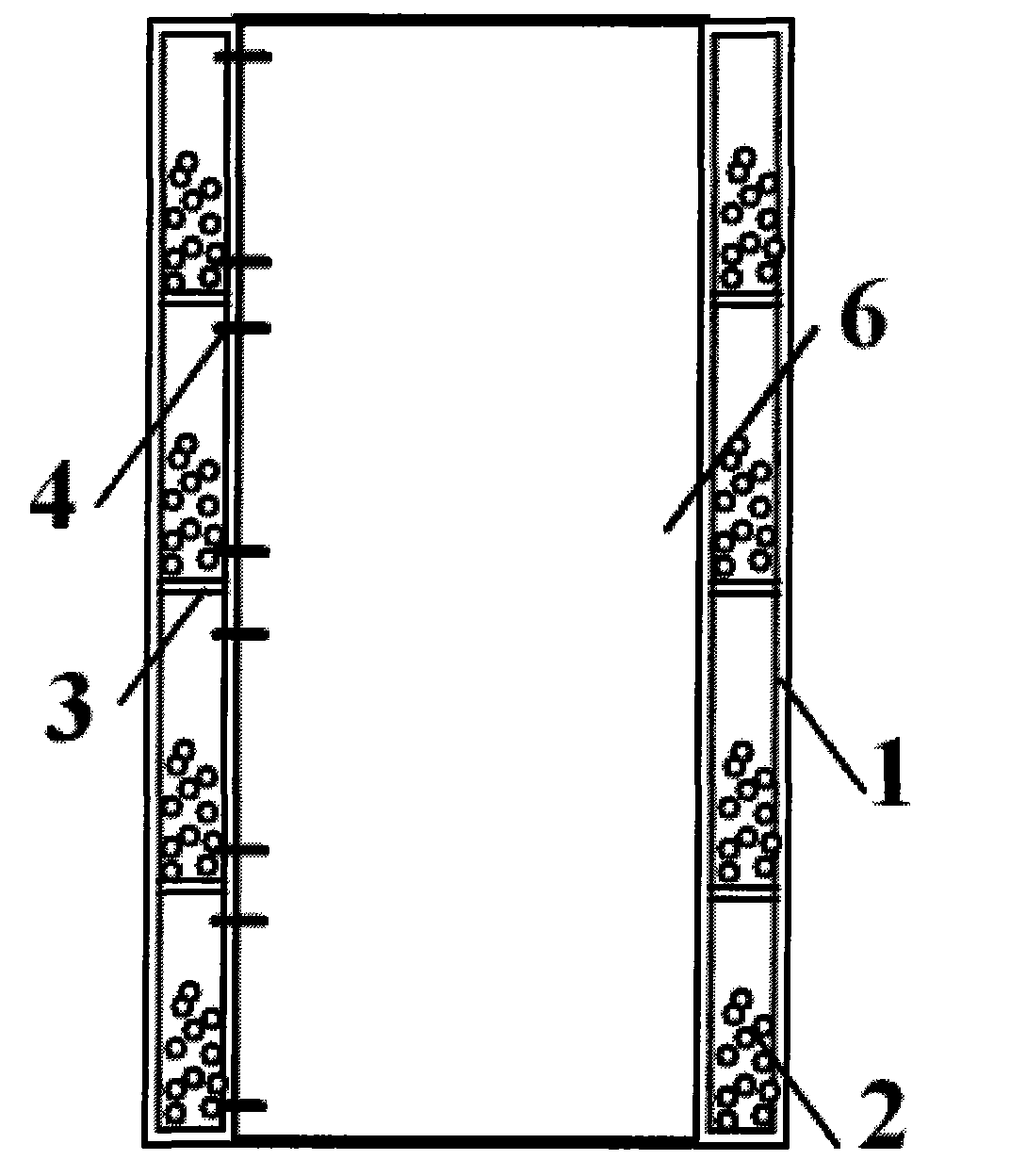

[0033] Such as Figure 4 and Figure 5 As shown, this embodiment mainly includes the box body 1, the damping particle group 2 placed in the box body, the internal partition plate 3 of the box body, the connecting member 4 and the original floor of the structure connected to the box body 1 at the lower part of the box body 1 7. The original floor of the structure here 7 is the original top floor of the structure.

[0034] The material of the box body 1 is a common building steel plate, and the connecting member 4 formed by high-strength bolts is riveted with the original floor 7 of the structure at multiple places. The box 1 is generally arranged continuously and uniformly on the upper part of the original floor 7 of the structure, and the length and width should be consistent with the length and width of the column network where the box 1 is located. The internal partition 3 of the box body 1 is a flat steel plate with a thickness of 8 mm, and the box body 1 is evenly divide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com