Fiber optic gyro framework designed according to sectorization

A fiber optic gyroscope and functional partitioning technology, applied in Sagnac effect gyroscopes and other directions, can solve problems such as unreasonable conduction and heat flow direction, affecting the accuracy of fiber optic gyroscopes, and less consideration of air tightness functional requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings.

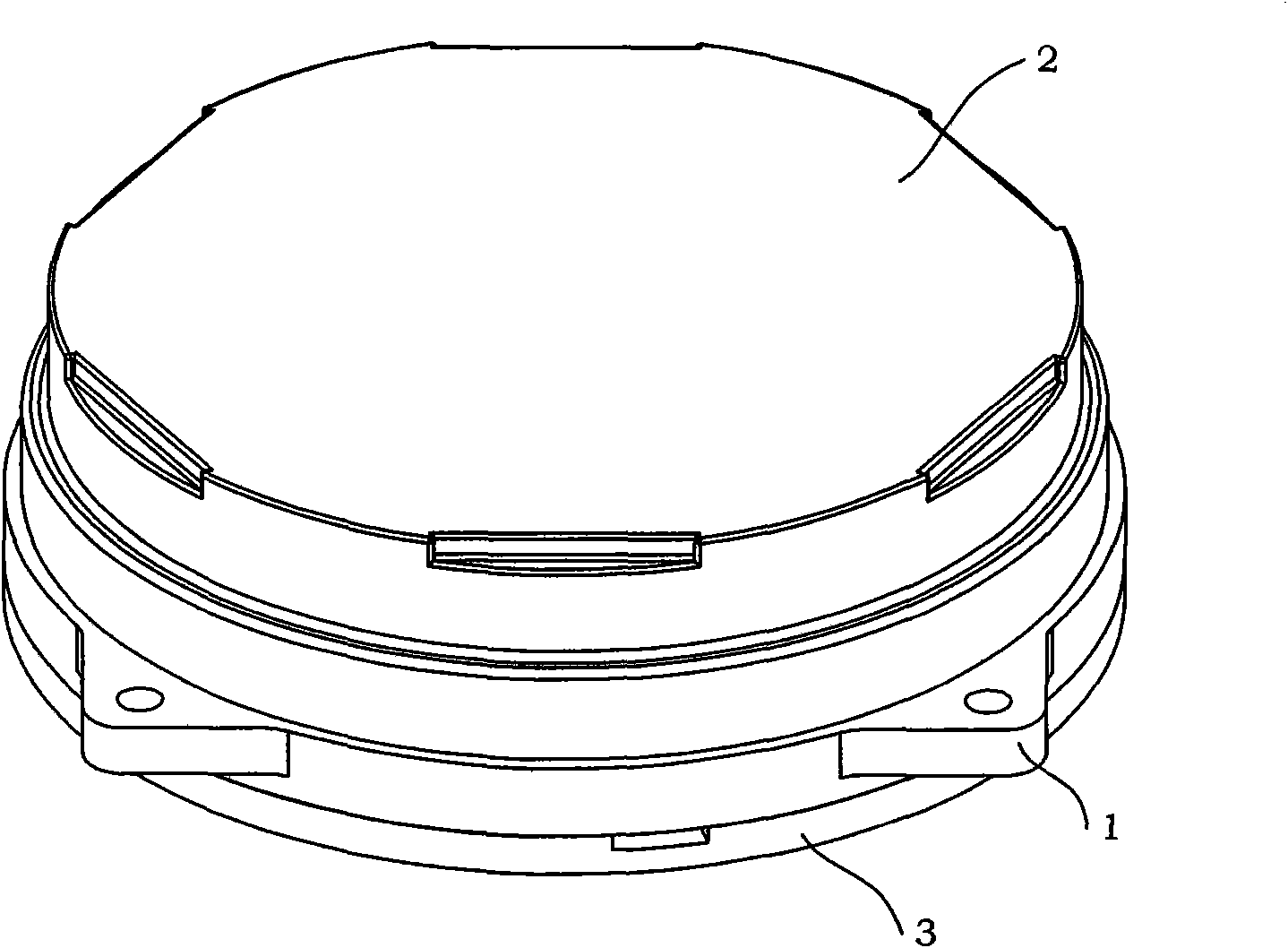

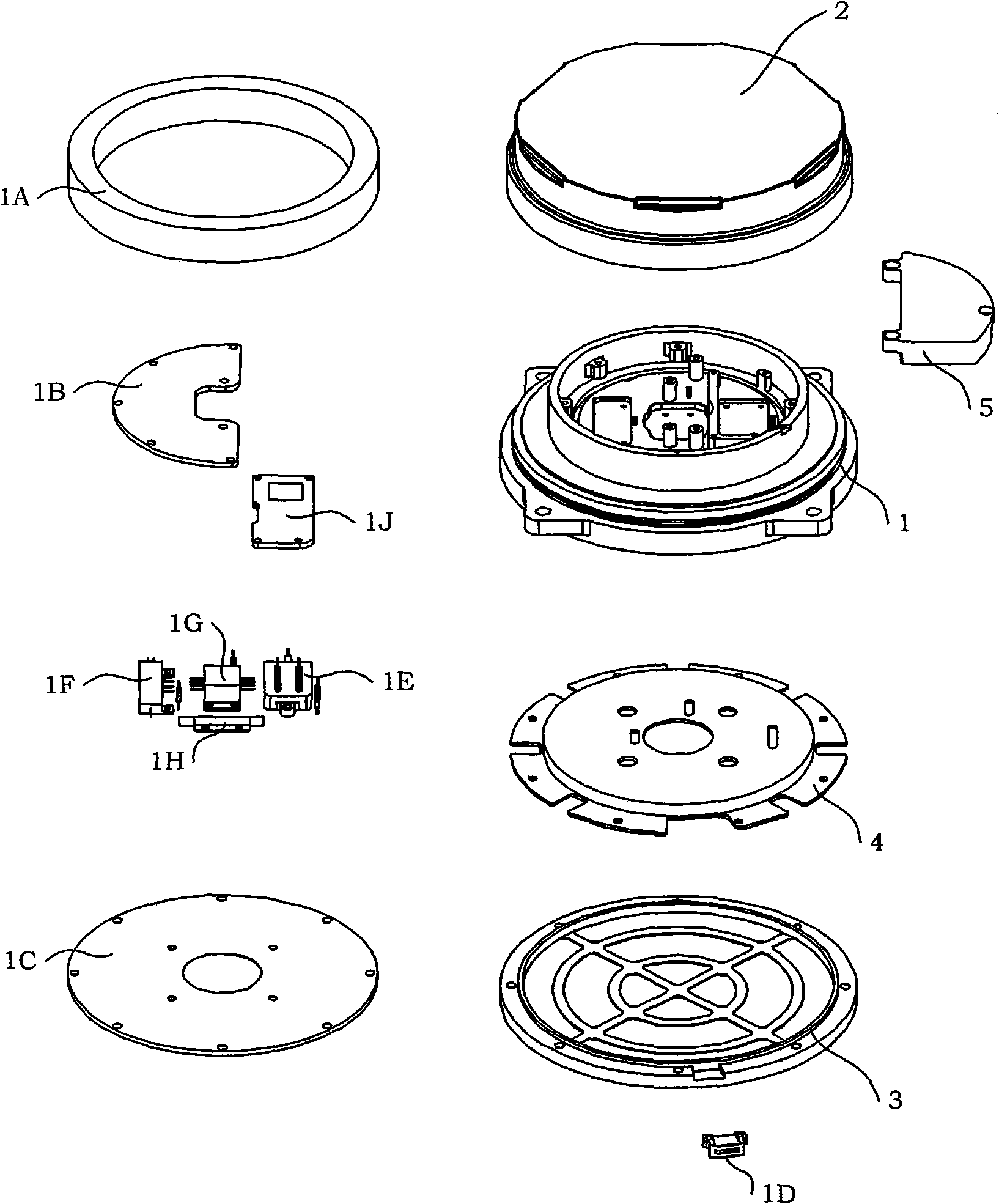

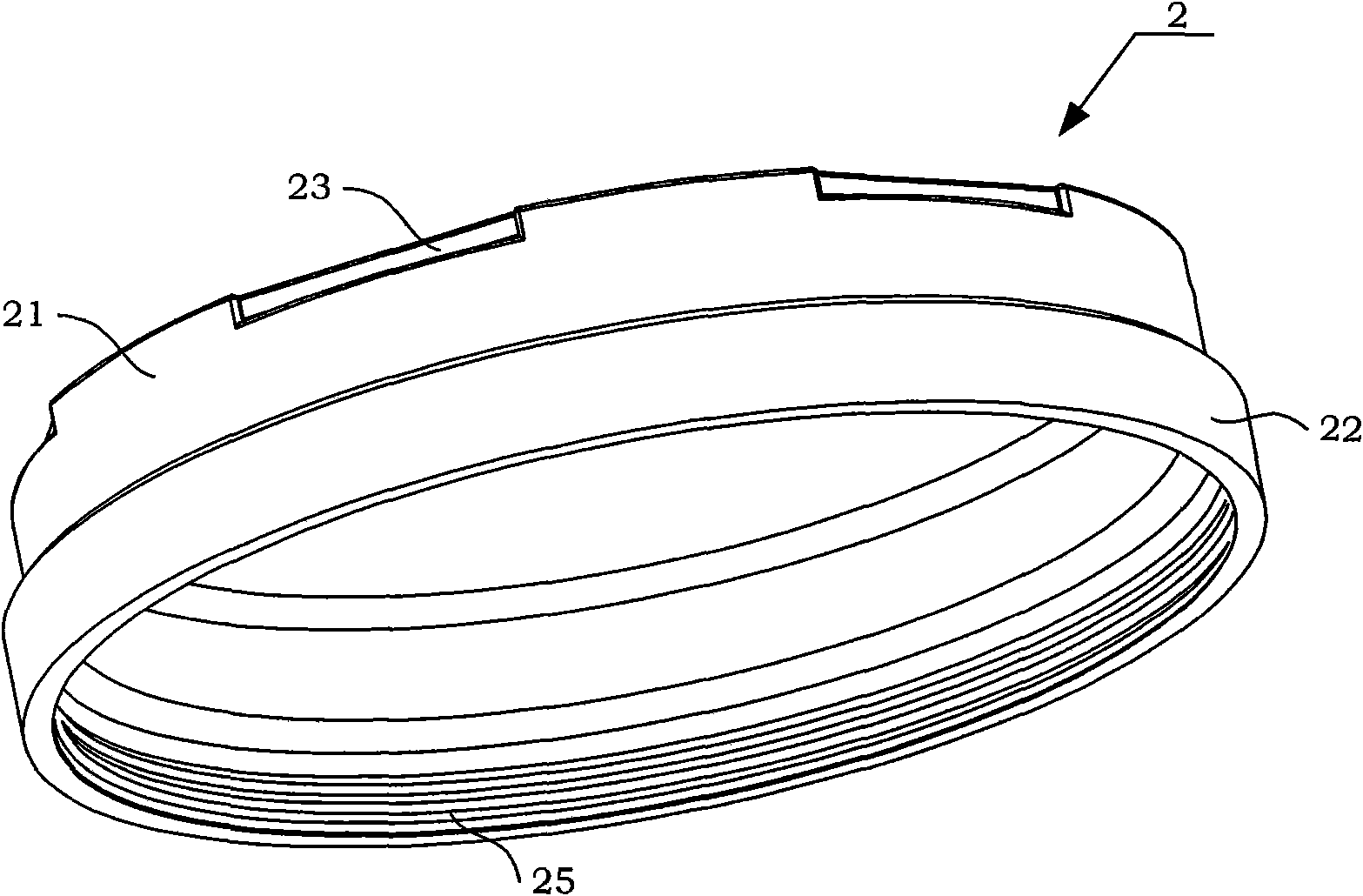

[0040] see figure 1 As shown, the present invention is a fiber optic gyroscope skeleton designed according to functional divisions. The skeleton includes a skeleton body 1 , an upper cover 2 , a lower cover 3 , a magnetic shield 4 and a front cover 5 . The upper cover 2 is screwed on the B circular platform section 12 of the frame body 1; the front cover plate 5 is installed on the L-shaped partition 104 in the frame body 1, and the magnetic shield 4 is placed between the frame body 1 and the lower cover 3 , and the magnetic shield 4 is installed on the first step of the skeleton body 1 , and the lower cover 3 is installed at the lower end of the skeleton body 1 .

[0041] (1) Skeleton body 1

[0042] see figure 1 , Figure 1A , Figure 6 , Figure 6A , Figure 6B As shown, the skeleton body 1 is integrally processed into a molded part, and is a disc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com