Physical simulation method for plastic deformation of friction welding joint

A technology of physical simulation and plastic deformation, applied in flow characteristics, measuring devices, instruments, etc., can solve the problems of large research errors, and it is difficult to reveal the flow behavior of plastic metal in friction welding joints, so as to achieve convenient operation, easy observation, and saving cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

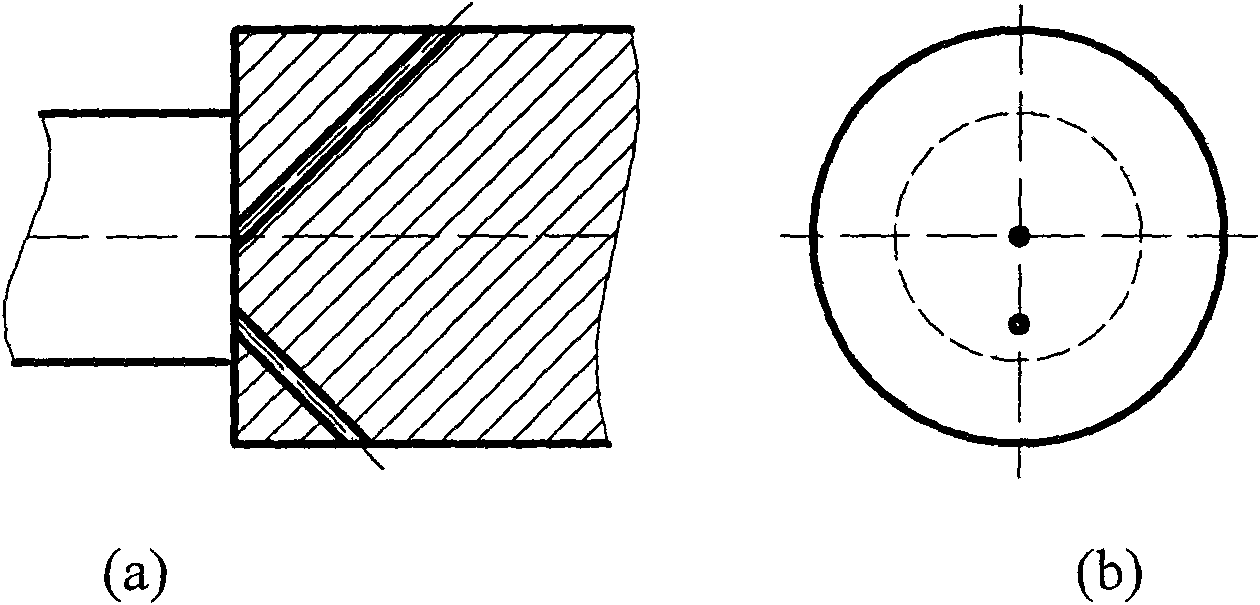

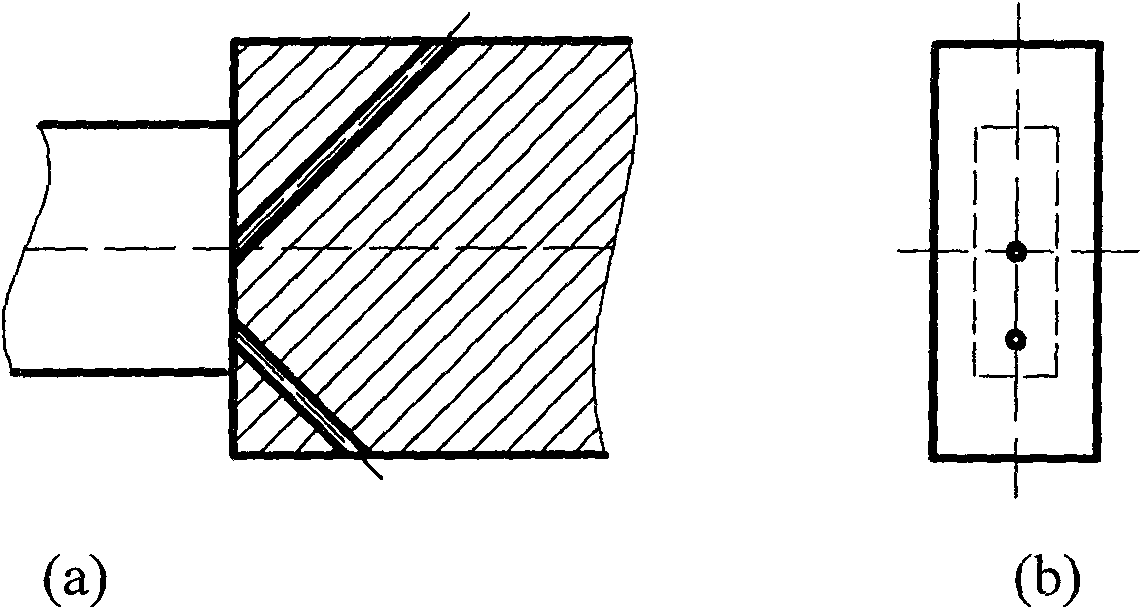

[0036] This example studies the deformation behavior of linear friction welding joints. Firstly, aluminum alloy is selected as the research object, and stainless steel is sampled as the dual sample. The characteristic size of the aluminum alloy is a rectangular section of 10mm×17mm, and the sample length is 50mm; due to the large deformation of the aluminum alloy, the characteristic size of the stainless steel is 35mm×60mm, and the sample length is also 50mm. A linear friction welding machine is used for welding, the vibration frequency is 20Hz, the amplitude is 3mm, the axial pressure is 30MPa, the friction time is 10s, and no upsetting force is applied. At the same time, a thermometer was used to measure the temperature of the central interface (refer to figure 2 ), record the axial displacement of the sample. After welding, the aluminum alloy is cooled to room temperature by water cooling. The research object obtained during the whole process is poorly combined with the ...

Embodiment 2

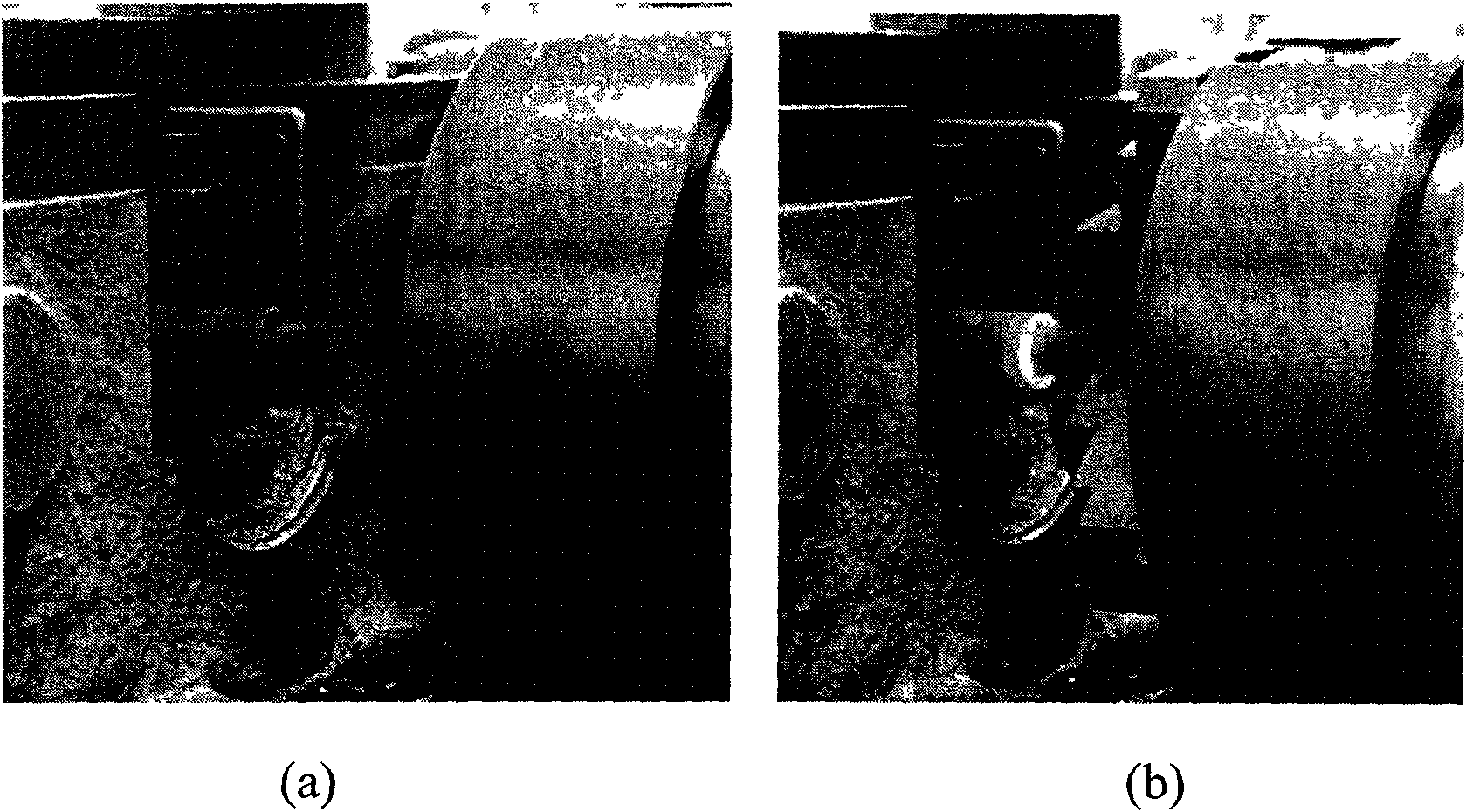

[0038] The 20# steel bar with a diameter of 20mm is used as the research object. For the convenience of clamping, the length is 150mm; the TZM molybdenum alloy rod with a diameter of 30mm is used as the dual sample, and the length is 150mm for the convenience of clamping. The continuous drive friction welding machine was used for the test, the rotating fixture clamped 20# steel, and the moving fixture clamped the molybdenum alloy (see attached image 3 a); Friction test process parameters: friction pressure 10kN, rotation speed 1200rpm, friction time 3s, 5s and 7s, photos during the friction process are shown in the attachment image 3 b. After welding, the two workpieces were tapped separately, and the research object was air-cooled. After welding, the dual sample did not deform, and the research object had obvious burrs, and the burrs were well formed ( Figure 4 ). Measure the macroscopic quantity of joint plastic deformation ( Figure 5 ), both the axial shortening and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com