Liquid crystal display and method for assembling liquid crystal display

A technology for liquid crystal displays and display components, which is applied to static indicators, instruments, nonlinear optics, etc., can solve the problems of large volume, limited application of liquid crystal displays, and the inability of the backlight module 10 to have flexibility, so as to save manufacturing and assembly. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

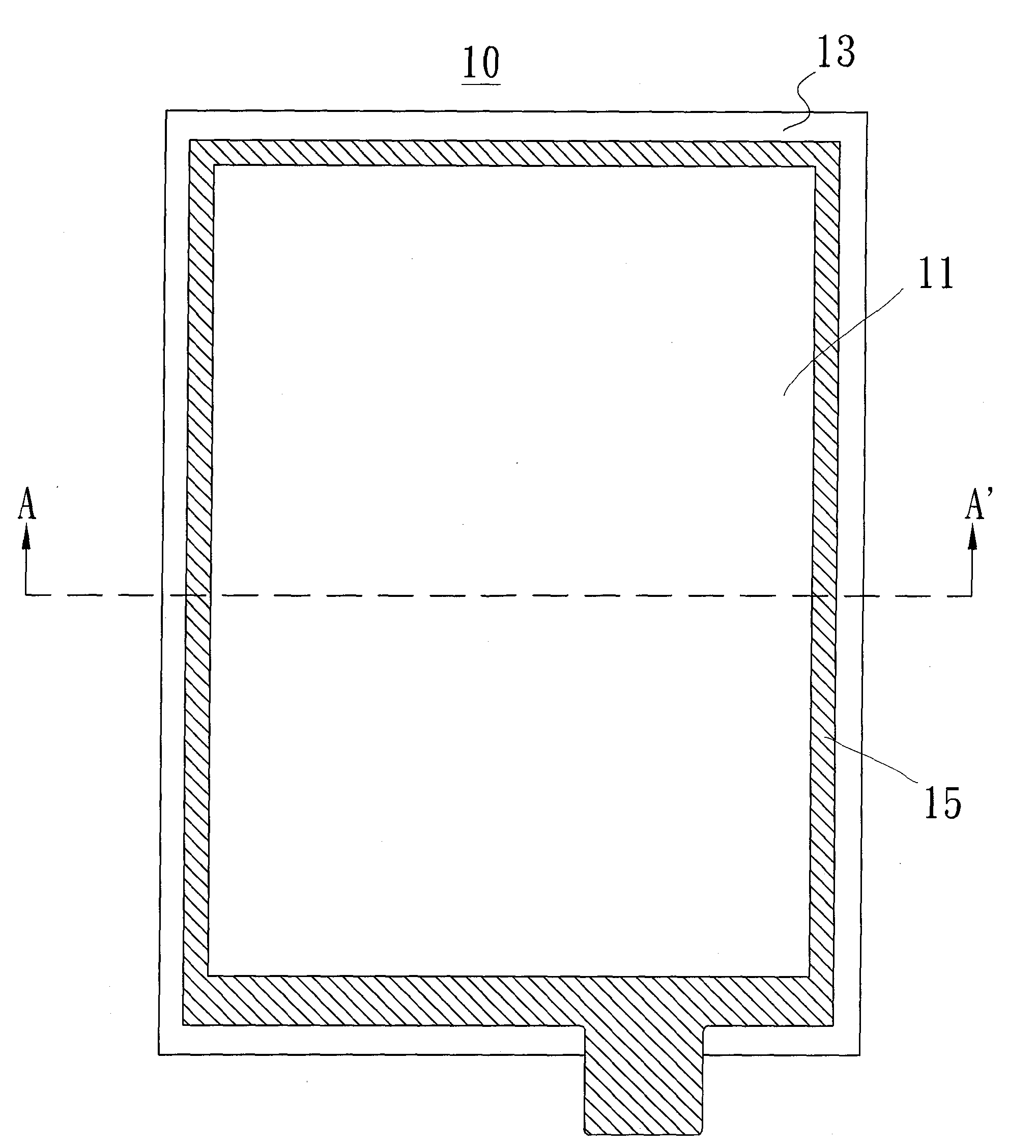

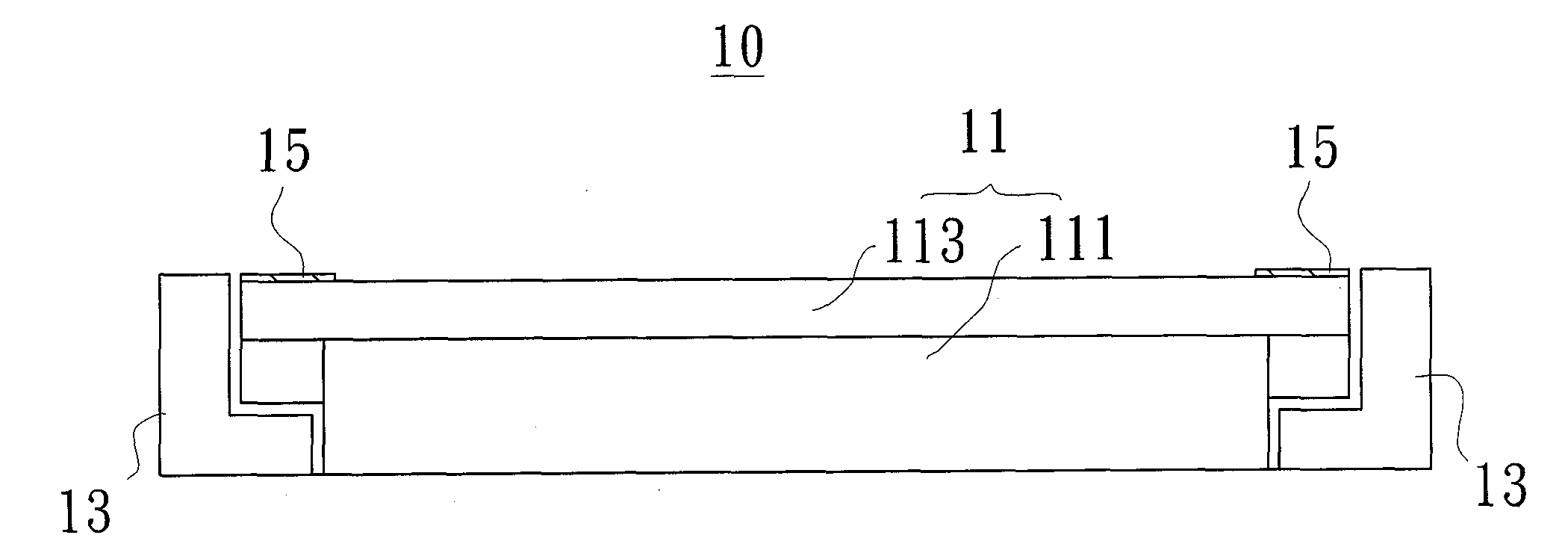

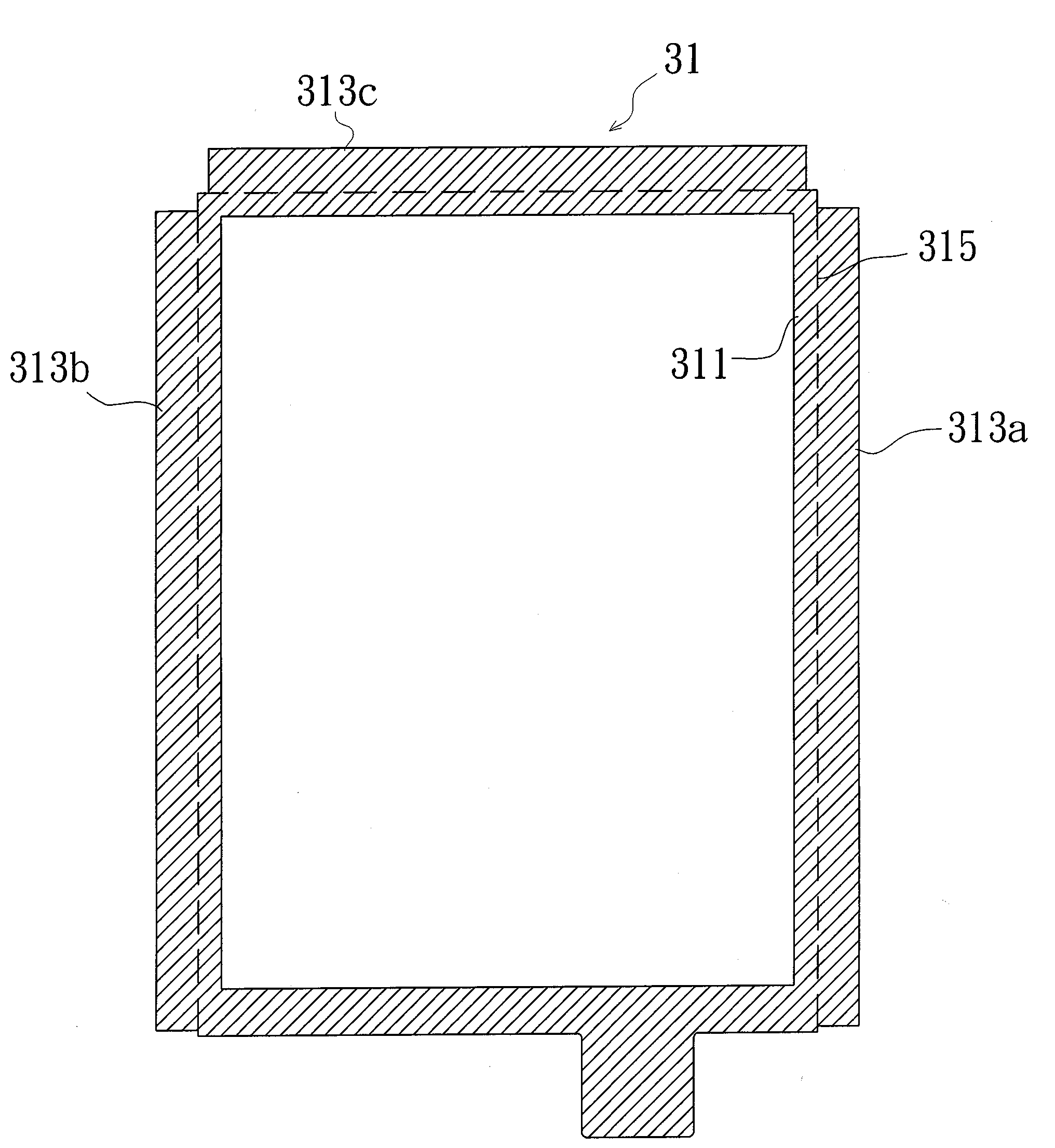

[0034] Please see first Figure 3A and Figure 3B , Figure 3A is a schematic diagram of tape 31, and Figure 3B is a schematic diagram of a liquid crystal display 30 using an adhesive tape 31 . Please also refer to Figure 4A , which is along Figure 3B The cross-sectional view of the B-B' section line to show the first embodiment of the present invention.

[0035] In the first embodiment of the present invention, the liquid crystal display 30 includes an adhesive tape 31 and a display component 33 . Wherein, the display assembly 33 has an upper surface 331, a lower surface 332 opposite to the upper surface 331, and a side edge 333; the adhesive tape 31 is composed of a substrate layer and an adhesive layer (not shown), and the substrate layer may include A light-shielding layer (not shown in the figure) or a reflective layer (not shown in the figure), the light-shielding layer is for example a black polyethylene terephthalate film layer (Polyethylene terephthalate, PET...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com