Dynamic bipolar drive power supply for piezoelectric ceramics and implementation method

A piezoelectric ceramic drive, bipolar technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc. Insufficient power drive capability and other problems, to achieve the effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

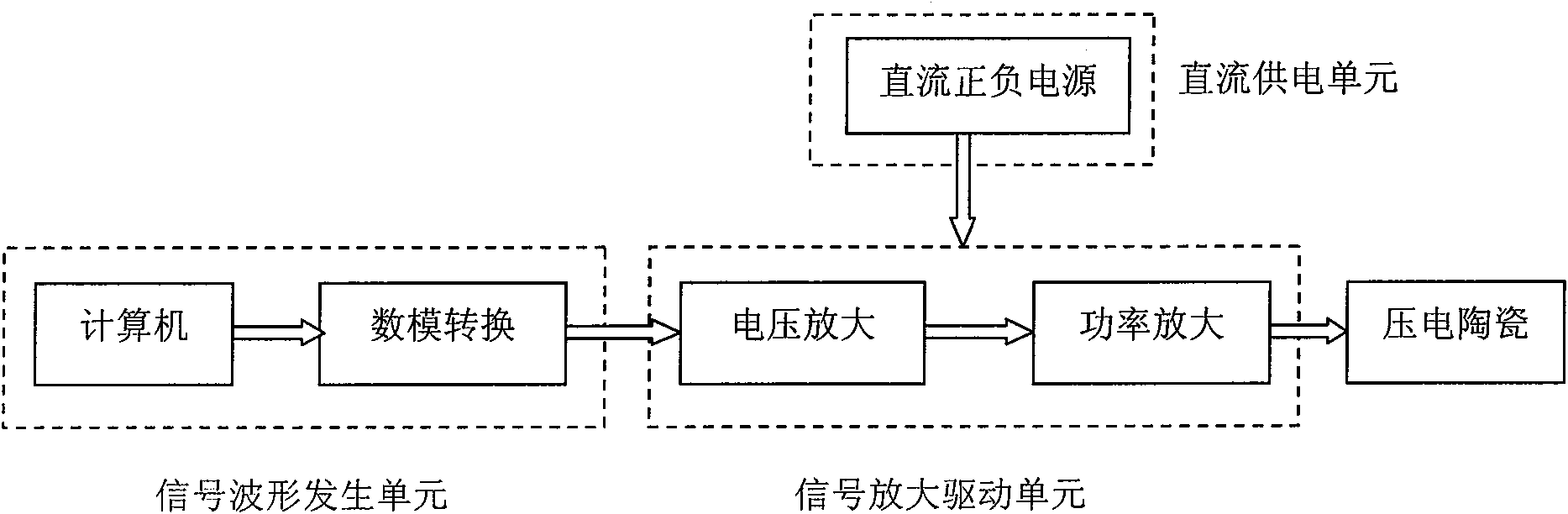

[0021] Such as figure 1 As shown, the present invention is mainly composed of a signal waveform generation unit, a signal amplification drive unit and a DC power supply unit. Among them, the signal waveform generation unit is used to generate various signal waveforms required in the load work. The signal amplification drive unit realizes the voltage and power amplification of the front-end signal to meet the power requirements required by the load. The DC power supply unit provides positive and negative DC voltages for the signal amplification drive unit. The process from the generation of the drive power signal to the drive is as follows: the required waveform discretization waveform data is generated through the software parameter setting, transmitted to the digital-to-analog converter through the USB of the computer, and the digital ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com