Method for manufacturing section steel with high strength and high toughness by using hot-rolling steel plate

A hot-rolled steel plate, high-strength and toughness technology, applied in the field of metallurgical manufacturing, can solve the problems of poor shape accuracy and flatness of section steel, high production cost, high energy consumption, etc., and achieve high flatness, low production cost and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

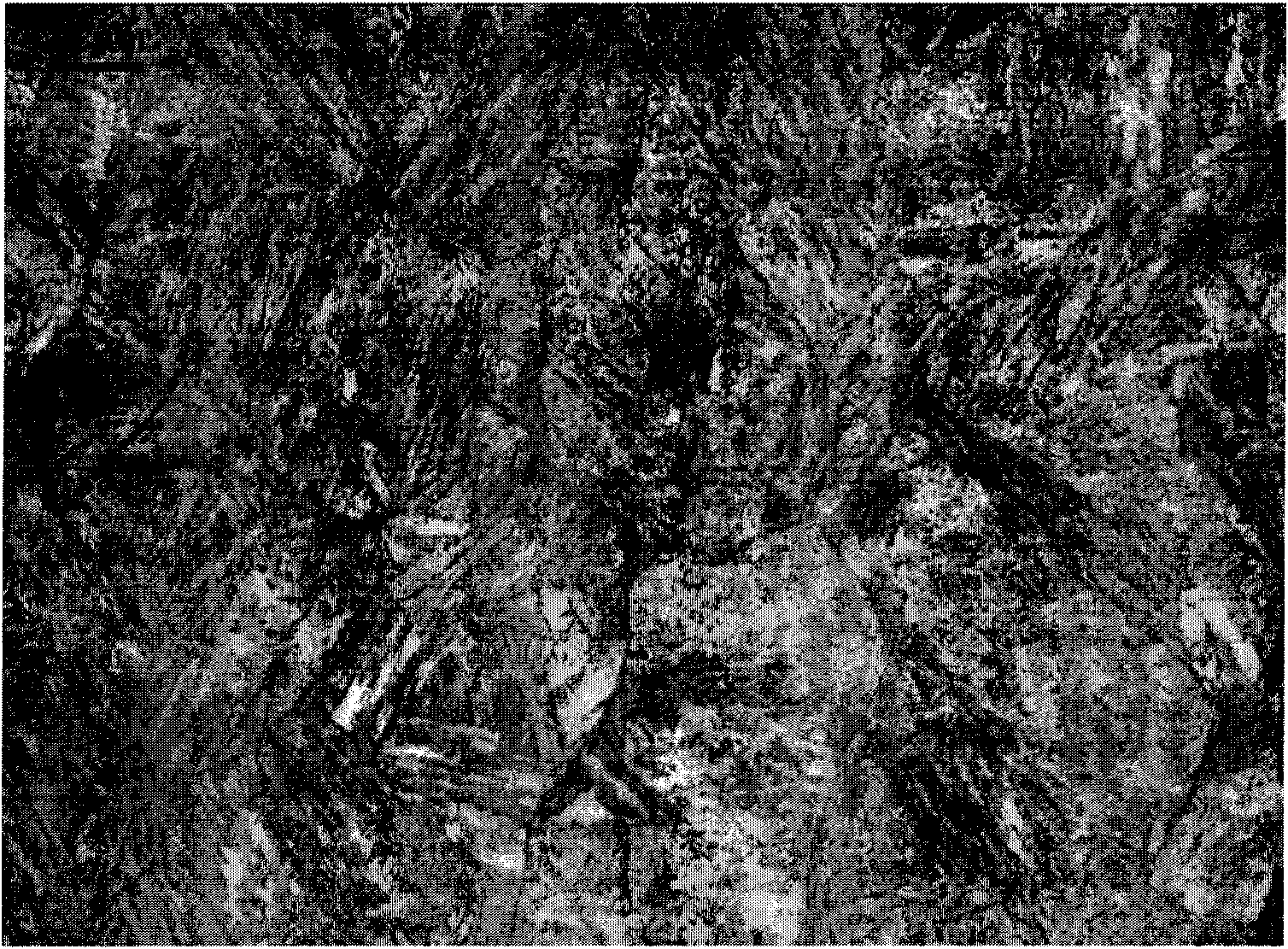

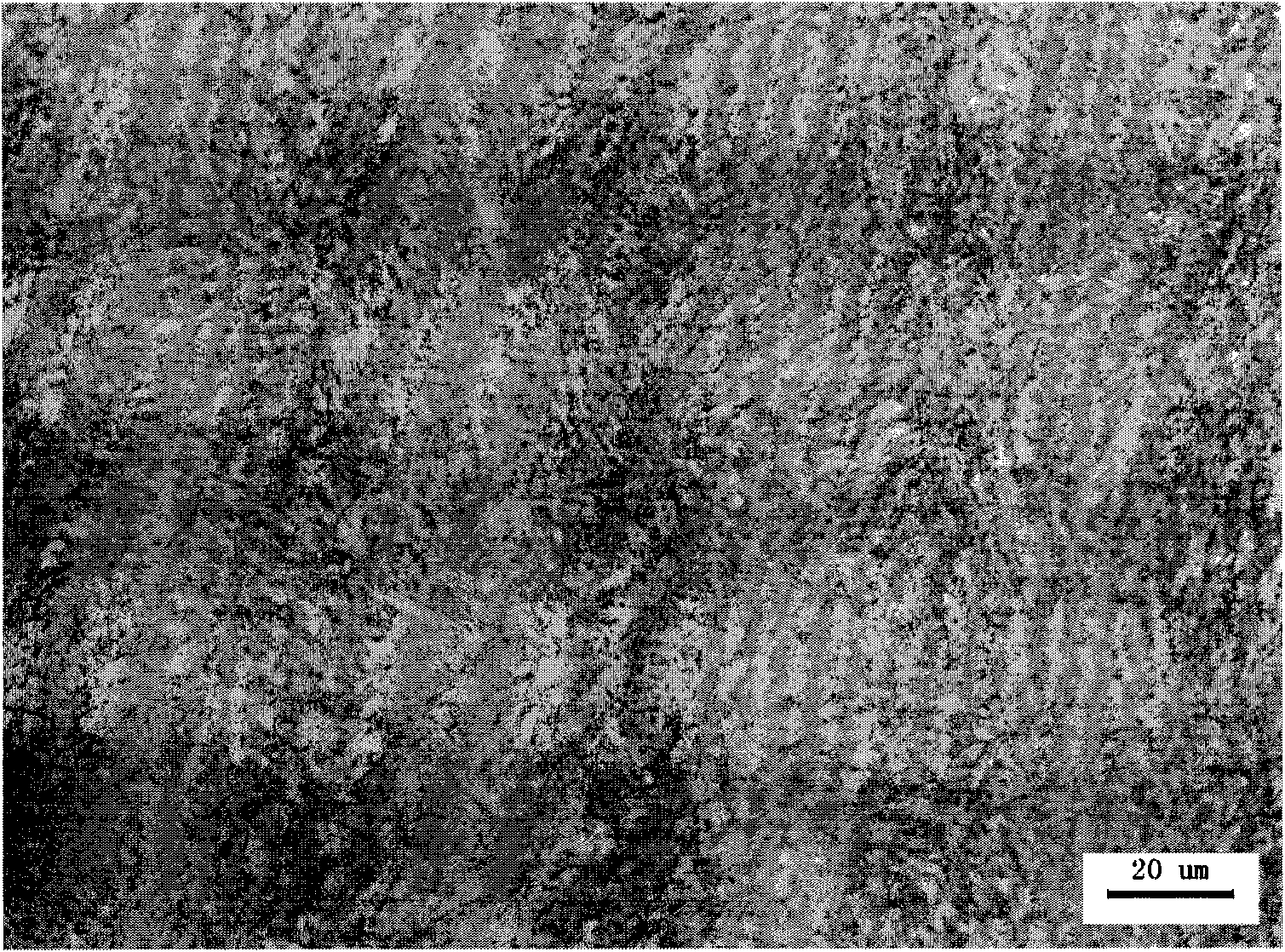

Image

Examples

Embodiment 1

[0062] When the thickness of the plate is 40mm, the mass percentage of each chemical component is:

[0063] C: 0.13%, Si: 0.25%, Mn: 1.2%, Ni: 1.45%, Cr: 0.4%, Mo: 0.55%, Cu: 0.15%, Nb: 0.012%, V: 0.02%, Ti: 0.015%, When Al: 0.035%, B: 0.00018%, P: 0.012%, S: 0.003%, N: 0.0035% steel plates are used to manufacture high-strength toughness steel, the specific manufacturing method steps are as follows:

[0064] 1) The above-mentioned hot-rolled steel plate is cut to the required size of the formed steel plate, under the clamping of the flat roller and the vertical roller, heated to 1050°C by an induction heater, and then the steel plate is bent into a shaped steel plate by a roll forming unit ;

[0065] 2) Send the section steel into the induction heater and heat it to 950°C for 110 seconds to make it austenitized;

[0066] 3) Water-cooled quenching, the quenching cooling rate is 16°C / S;

[0067] 4) After quenching, the section steel is heated to 650°C by tempering induction h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com