Nanophase bulletproof environment friendly solid tyre and manufacture method thereof

A solid tire, bulletproof wheel technology, applied in special tires, tire parts, tires, etc., can solve problems such as low elasticity, delayed transportation of people, money, and materials, and migration of toxic substances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

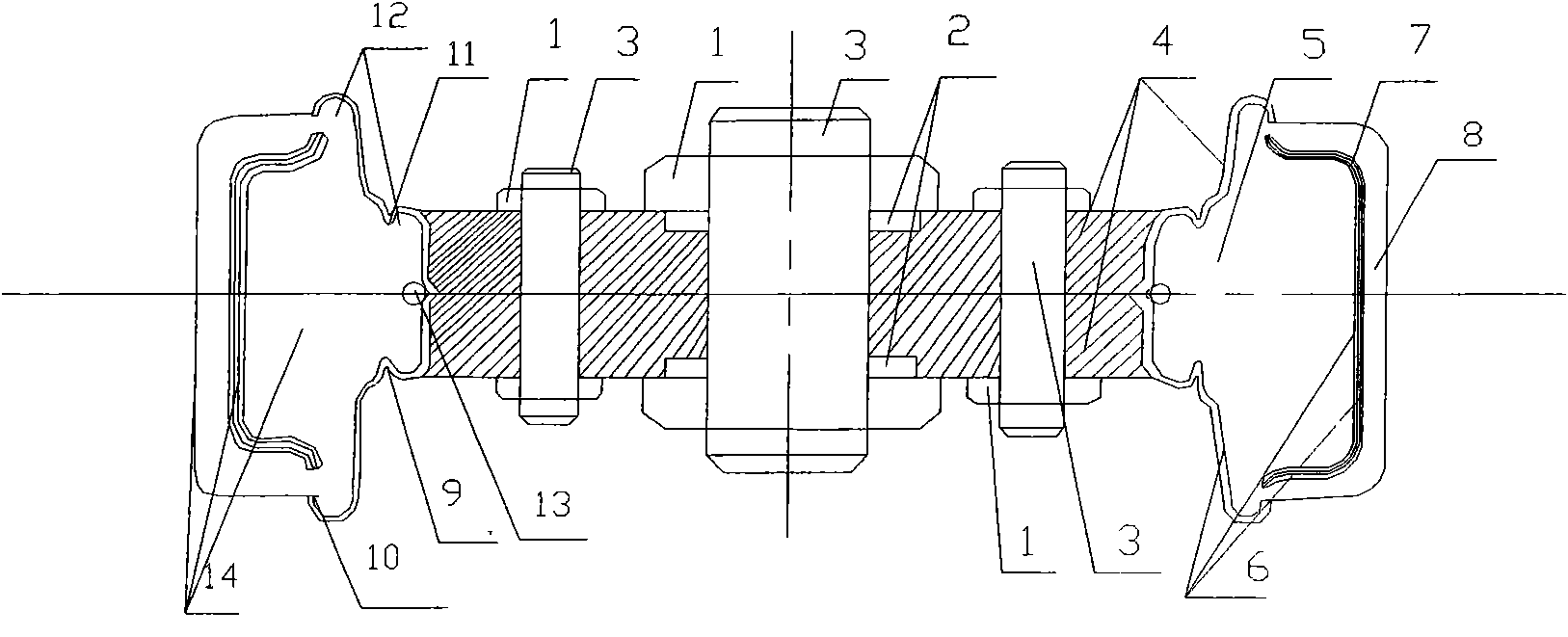

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

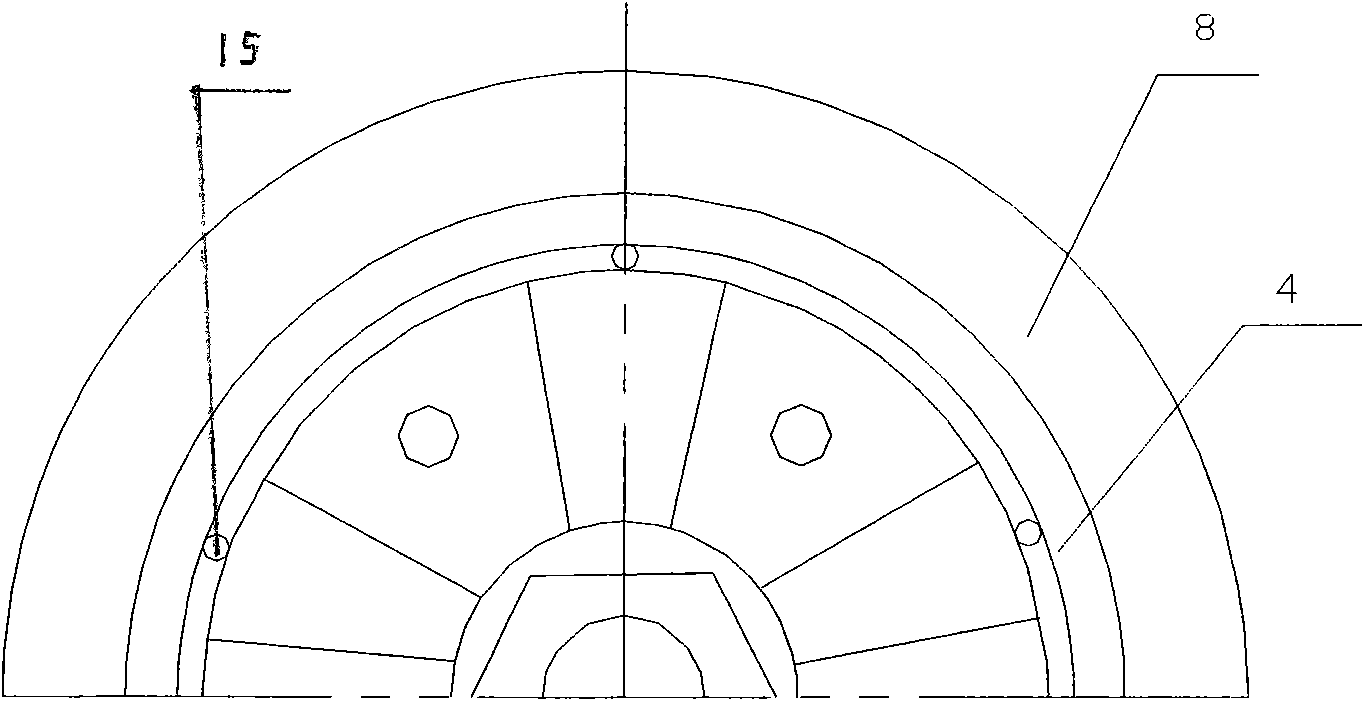

[0038] Depend on figure 1 As can be seen from the axial sectional view of the "nano bulletproof environmental protection solid tire" of the present invention, the "nano bulletproof environmental protection solid tire" of the present invention includes: 1. hub fasteners; 2. hub bearings; 3. bolt shafts; 4. bulletproof 5. Nano-rubber solid inner carcass; 6. Composite adhesive; 7. Bulletproof body provided; 8. Nano-urethane elastomer tread; 9. Convex groove of bulletproof hub; 10. Curling edge of bulletproof hub; Groove; 12 bulletproof tire inner sides; 13 heat dissipation grooves of bulletproof tires; 14 bulletproof tires; 15 heat dissipation holes.

[0039] It clasps the "nano-rubber solid inner carcass 5" outside the "bulletproof hub 4", and sets the "bulletproof body 7" structural material outside, and then compound and encapsulate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com