Biogas slurry ecological purification device and biogas slurry ecological purification method

A technology for ecological purification and biogas slurry, which is applied in chemical instruments and methods, biological water/sewage treatment, energy and wastewater treatment, etc. It can solve problems such as the dilution concentration that has not yet been retrieved, and achieve good results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below in conjunction with embodiment and with reference to accompanying drawing:

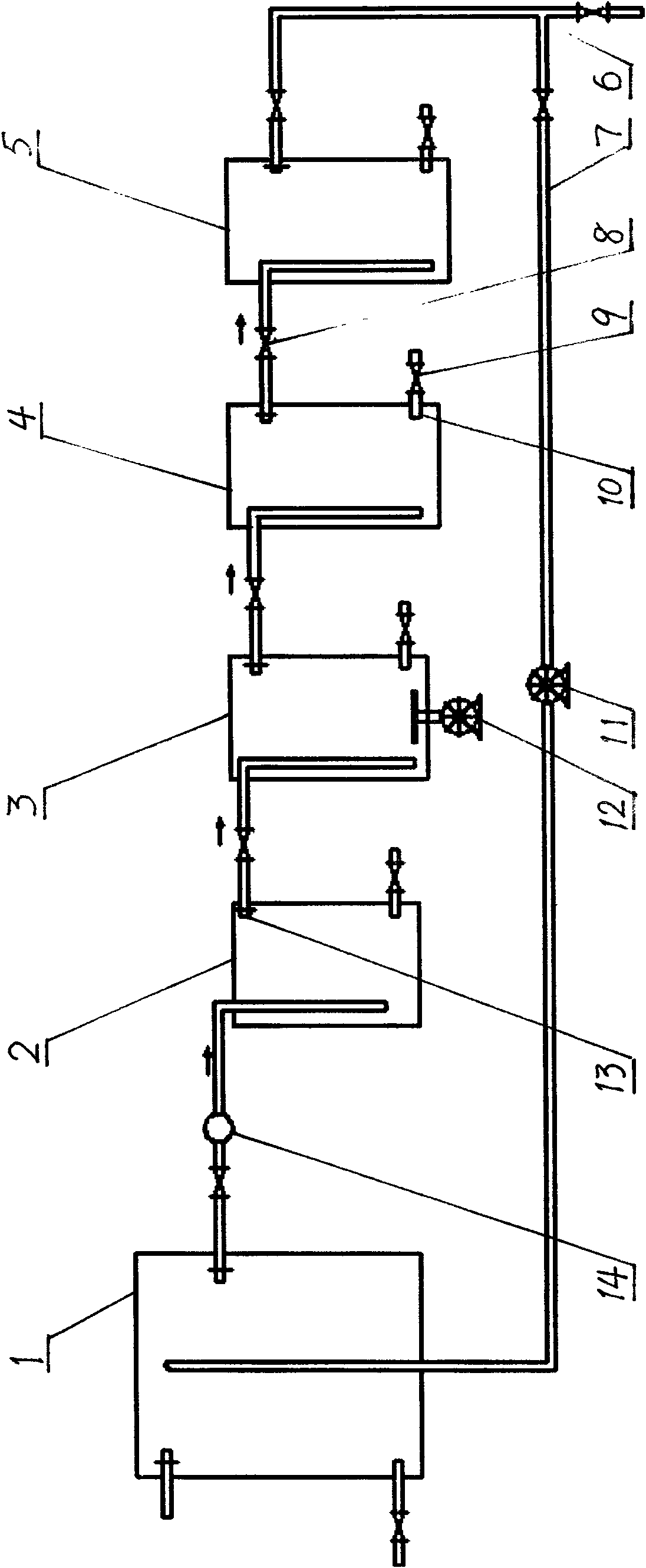

[0019] refer to figure 1 , the volume of regulating tank 1 is the largest, and the volumes of the other four tanks are similar or equal. The "single tank capacity base of the four tanks is 7 to 8 tons", which means that the capacity of each single tank is 7 to 8 tons or 14 to 8 tons. 16 tons or 21-24 tons or 70-80 tons or 700-800 tons, etc., in short, it is 7n-8n tons. If it is used for small or pilot laboratory tests, it can be 0.7-0.8 tons, and the rest can be analogized. Similarly, the "flow base is 140-230 liters / hour" can be 14-23 liters / hour or 280-460 liters / hour or 1400-2300 liters / hour, etc., in short, it is 140n-230n liters / hour, n are multiples. It should be emphasized that the multiple n of the expansion or reduction of the capacity of each tank and the multiple n of the increase and decrease of the flow rate must be the same valu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cover factor | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com