Process technique for producing blue and white delicate porcelain

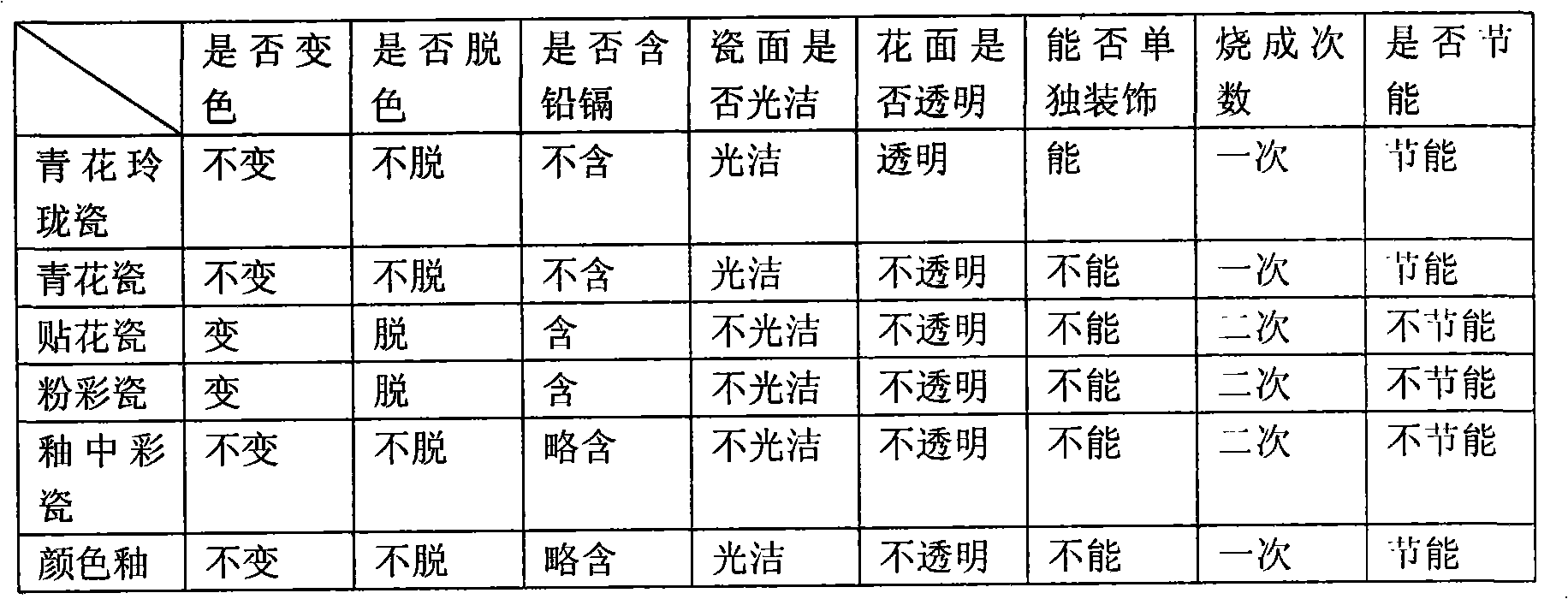

A production process, Linglong technology, applied in the field of blue and white Linglong porcelain production process, can solve the problems of not being able to reflect the decorative art effect of ceramics, increasing ceramic production costs and consumption, and harming the health of users, so as to save energy and production costs, and improve the porcelain quality. Delicate, smooth glaze effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

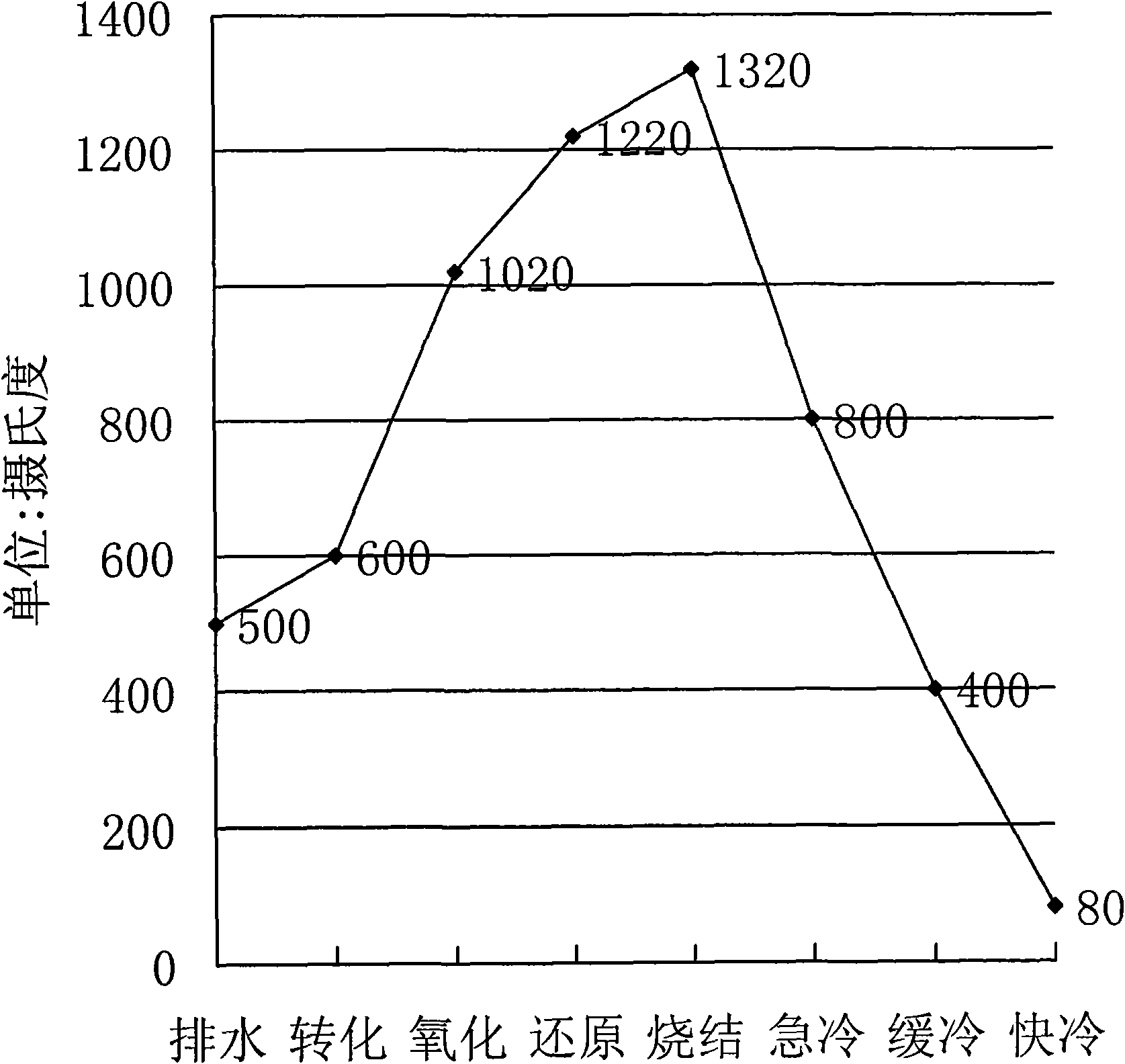

[0016] Process flow of the present invention is:

[0017] ① Process flow chart of round compacting process:

[0018] Compact→Drilling→Glaze pouring→Glaze washing→ Semi-drying → demoulding → drying → grinding blanks → receiving water → repairing blanks → drawing blanks (or printing blanks) → applying glaze → lifting glaze → putting on shelves → loading blanks → firing → porcelain

[0019] ②Cutter grouting process flow chart:

[0020] Grouting→semi-drying→demoulding→drilling (or carving blank)→glazing filling→drying→blank trimming→water absorption→painting blank (or printing blank)→glazing→glazing→shelf→loading blank→sintering→porcelain

[0021] The main raw material formula and technical parameter of specific embodiment are:

[0022] Clay formula: Nangang soil 70%, remaining dry soil 10%, Xingzi soil 20%

[0023] Moisture content: blade process forming 23-24%, rolling process forming 25-26%, grouting process forming 35-38%.

[0024] Surface glaze (green glaze) formula: (F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com