Synthesis method of 4-cyanopyridine

A technology of cyanopyridine and synthesis method, which is applied in the field of synthesis of 4-cyanopyridine, and can solve the problems of low conversion rate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The raw material 4-picoline and ammonia are vaporized and preheated to 180-330°C, then enter the mixer and mix with air evenly, and then distribute through the distributor on the upper part of the fixed-bed reactor and then enter the fixed-bed reactor filled with catalyst, controlled The reaction temperature is between 330-450°C, the pressure at the top of the reactor is controlled at 0.020-0.070KPa, the reaction temperature is controlled by molten salt, and the reaction gas after the reaction is separated by condensation and freezing to obtain crude 4-cyanopyridine, crude Go to rectification to get the finished product 4-cyanopyridine.

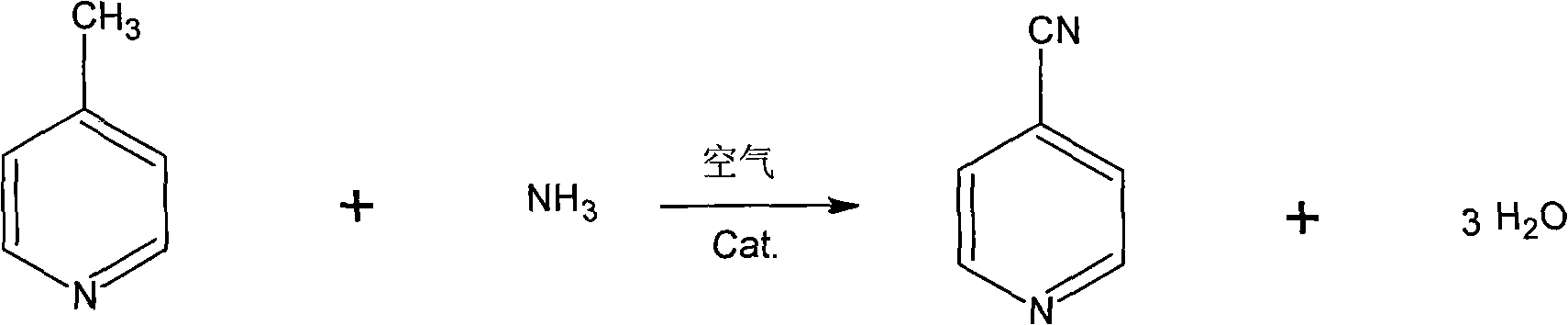

[0022] Reaction equation:

[0023]

[0024] Described catalyzer is the 4-cyanopyridine ammoxidation catalyst that is carrier with aluminum oxide, and the composition of catalyzer is as follows:

[0025] A a B b C c Cr 10 o x

[0026] Wherein A=Li (or several combinations in Na or Ti or Na, Li, Ti);

[0027] B=V (or several c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com