Device capable of converting high-energy X ray image into visible light image

An image conversion and visible light technology, applied in the field of high-energy physics, can solve the problems of difficult imaging, low resolution of visible light images, and impossible X-ray imaging, and achieve the effect of convenient testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

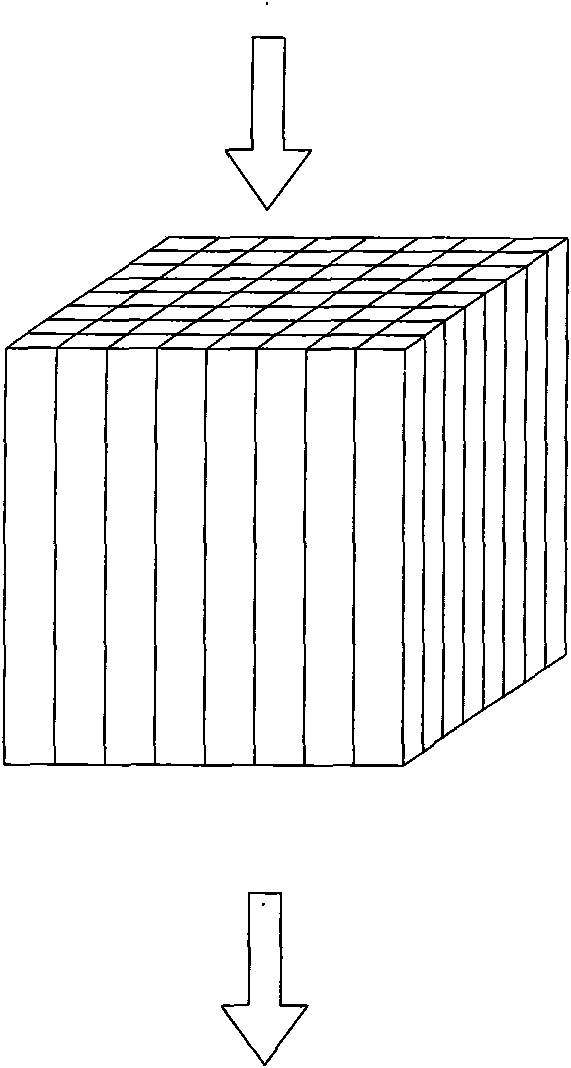

[0012] Embodiment 1: see Fig. 1.

[0013] The crystal array is composed of several yttrium lutetium silicate (LYSO) cuboid crystal columns. The length of each crystal column is 1 cm, and the cross section is a square with a side length of 0.5 mm.

[0014] The side of the crystal column is polished and plated with two layers of metal. The inner layer is plated with aluminum (melting point 658 degrees Celsius) with a thickness of 0.3 microns, and the outer layer is plated with lead (melting point 327.4 degrees Celsius) with a thickness of 0.15 mm. One cross-section (incident surface) of the crystal column is polished and coated with an aluminum layer with a thickness of 0.3 microns, and the other cross-section (exit surface) is coated with a visible light anti-reflection film with a center wavelength of 420 nanometers.

[0015] After coating, the cross section of each crystal column is about a square with a side length of 0.8 mm, and each side is polished and flattened before b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com