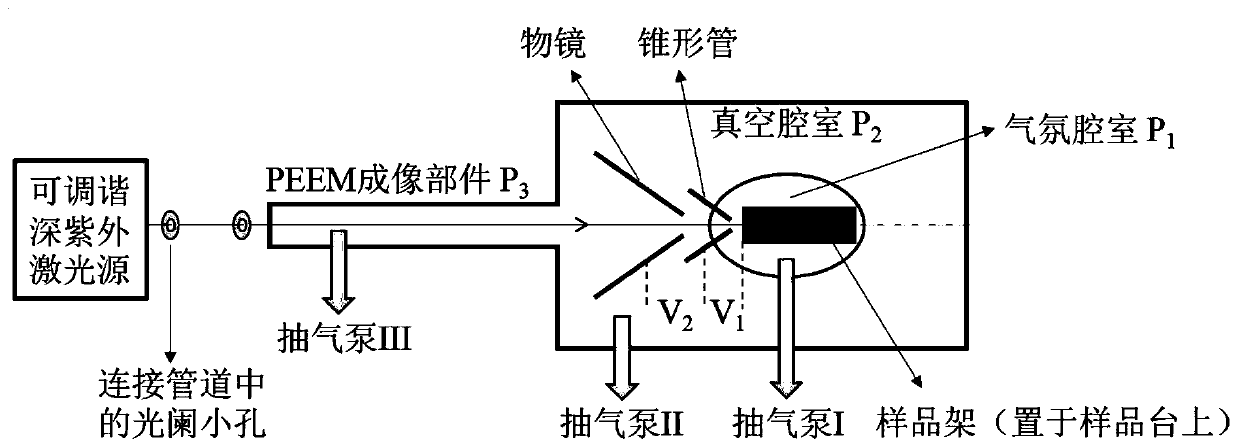

An imaging system and method combining a tunable deep ultraviolet laser source with a near-atmospheric pressure light emission electron microscope

An electron microscope and imaging system technology, applied in the field of surface scientific research, can solve the problems of limited synchrotron radiation light source resources and limit the wide application of PEEM, and achieve the effect of improving spatial resolution and application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

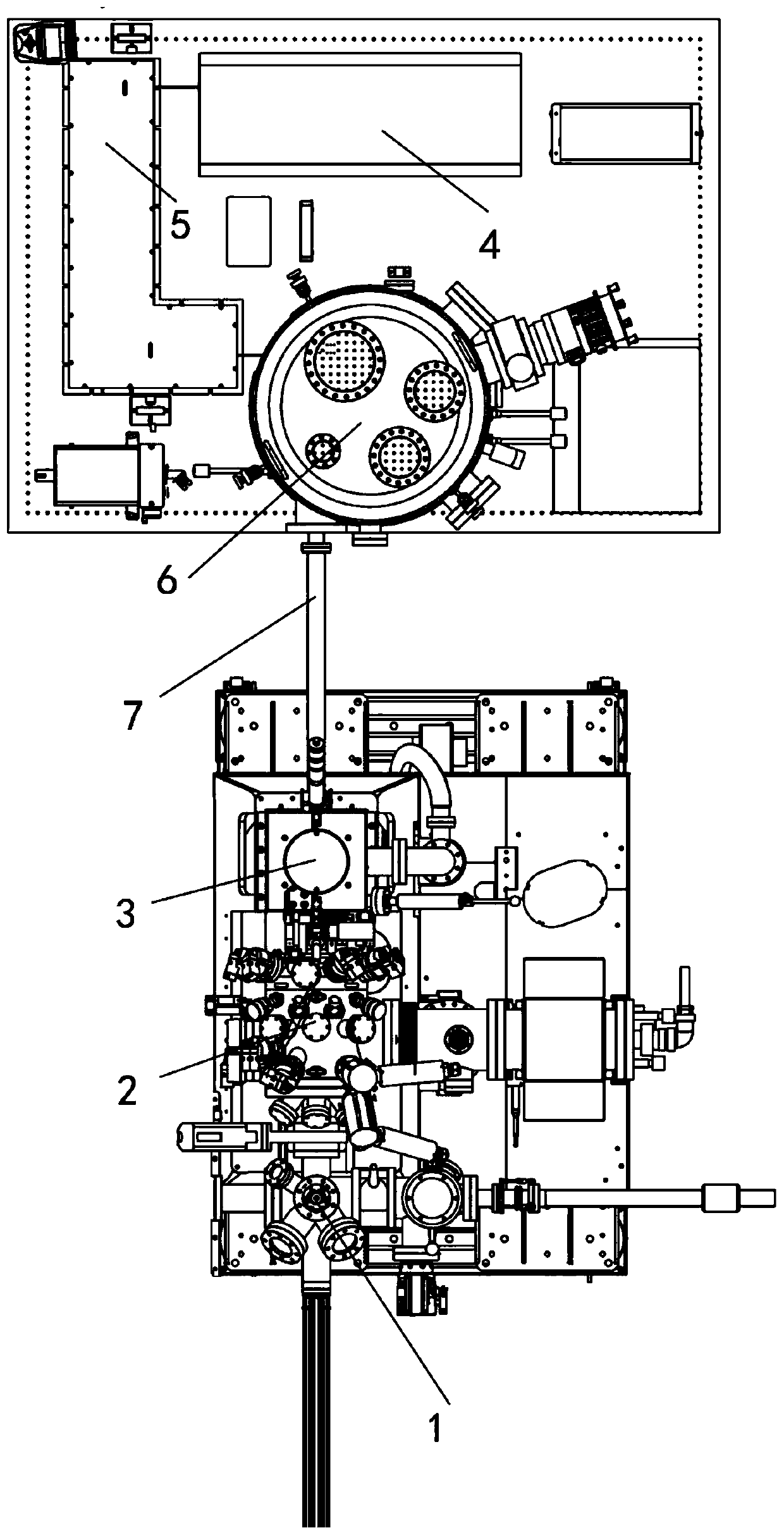

Method used

Image

Examples

Embodiment 1

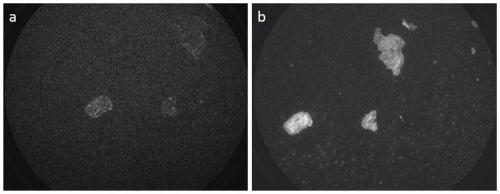

[0056] The graphene structures prepared on the surface of Nb-doped STO were respectively illuminated by Hg light source ( image 3 a) and deep ultraviolet light source (210nm) ( image 3 b) PEEM imaging under ultra-high vacuum conditions for the excitation light source. The atmosphere chamber is a vacuum environment, the potential difference between the sample and the conical tube is 5kV, and the potential difference between the conical tube and the objective lens is 10kV. The image size is 50 microns, the work function of STO is relatively high, the surface photoelectron signal is weak, which appears as dark areas, and the graphene structure shows high gray scale. Excite the surface with a deep ultraviolet laser because of its high energy, image 3 b shows higher graphene brightness and higher structural resolution. This case shows that deep ultraviolet laser has improved the application field of PEEM.

Embodiment 2

[0058] Single-layer graphene structure grown on Ru(0001) single crystal surface, PEEM imaging of the intermediate state with Hg lamp as excitation light source ( Figure 4 ). The nitrogen pressure in the atmosphere chamber is 0.12mbar, and after the gas differential pumping, the pressure of the PEEM imaging chamber is 1.2×10 -6 mbar, the pressure at the detector is 1.2×10 -8 mbar. The potential difference between the sample and the conical tube is 5kV, and the potential difference between the conical tube and the objective lens is 10kV. With an image size of 14 μm, the photoelectron signal on the Ru substrate surface is weak, appearing as dark areas. Figure 4 The lower curve corresponds to the gray distribution of the yellow line area in the picture, and the resulting spatial resolution is about 25nm. This case illustrates that the near-atmospheric pressure PEEM device in the present invention can achieve higher spatial resolution in an atmosphere of 0.12 mbar.

Embodiment 3

[0060] The single-layer graphene structure grown on the Ru(0001) single crystal surface was imaged by PEEM under near-atmospheric pressure using a Hg lamp as the excitation light source ( Figure 5 ). The nitrogen pressure in the atmosphere chamber is 1.2mbar. After the gas differential pumping, the pressure of the PEEM imaging chamber is 1.2×10 -5 mbar, the pressure at the detector is 1.2×10 -7 mbar. The potential difference between the sample and the conical tube is 0.3kV, and the potential difference between the conical tube and the objective lens is 5.7kV. Figure 5The lower curve corresponds to the gray level distribution of the yellow line area in the picture, and the resulting spatial resolution is about 100nm. This case shows that the near-atmospheric pressure PEEM device in the present invention can realize PEEM imaging in a near-atmospheric pressure atmosphere of 1.2 mbar, reaching a spatial resolution of 100 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com