Photoemission electron microscopy imaging method and imaging system capable of working under atmospheric conditions close to normal pressure

A technology of emitting electrons and microscopic imaging, which is applied in the direction of electrical components, circuits, discharge tubes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

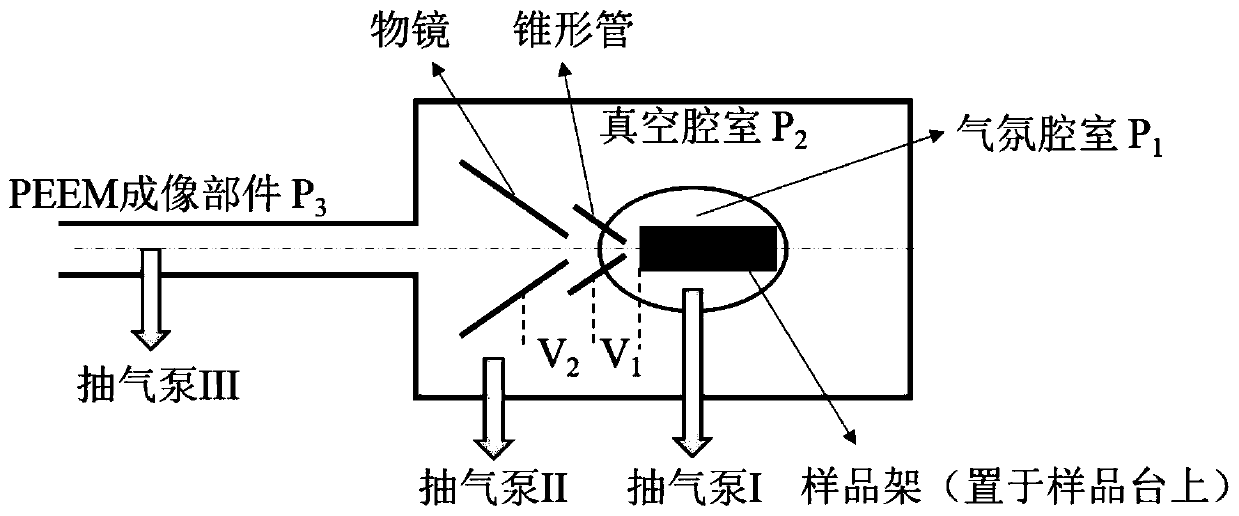

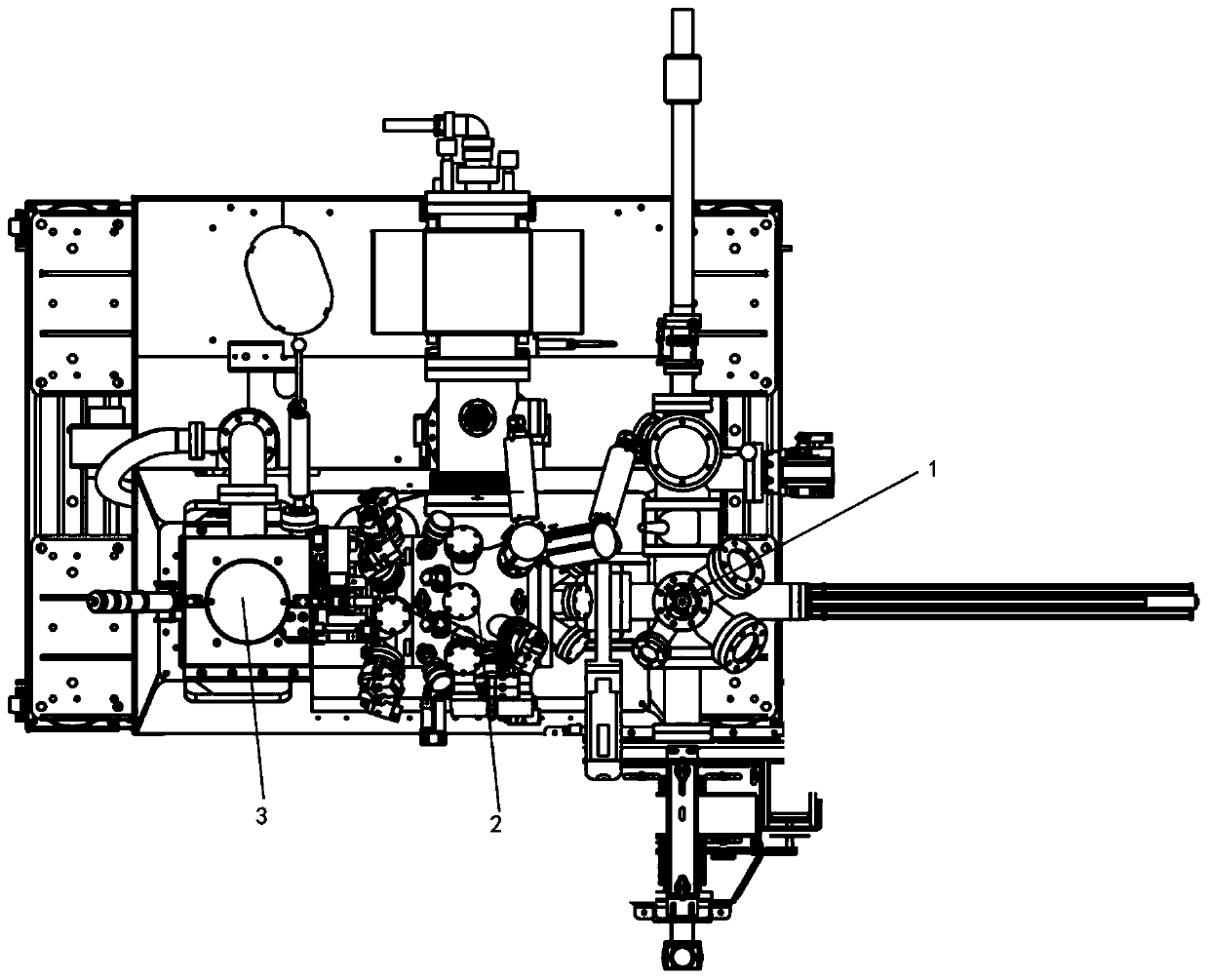

Method used

Image

Examples

Embodiment 1

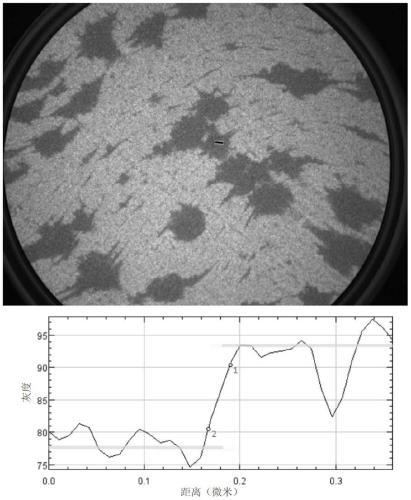

[0044] PEEM imaging under ultra-high vacuum conditions ( image 3 ). The sealed atmosphere chamber is a vacuum environment, the potential difference between the sample and the conical tube is 5kV, and the potential difference between the conical tube and the objective lens is 10kV. The sample is a single-layer graphene structure grown on the surface of a Ru(0001) single crystal. Hg lamp light source is used, the image size is 14 microns, the photoelectron signal on the surface of Ru substrate is weak, which appears as a dark area, and the graphene structure shows a higher gray scale. image 3 The lower curve corresponds to the gray level distribution of the black line area in the figure, and the resulting spatial resolution is about 20nm (the distance between points 1 and 2 in the curve). This case illustrates that the NAP-PEEM device of the present invention can achieve a spatial resolution comparable to conventional PEEM under ultra-high vacuum conditions.

Embodiment 2

[0046] PEEM imaging of the intermediate state ( Figure 4 ). The nitrogen pressure in the sealed atmosphere chamber is 0.12mbar, and after the gas differential pumping, the pressure of the PEEM imaging chamber is 1.2×10 -6 mbar, the pressure at the detector is 1.2×10 -8 mbar. The potential difference between the sample and the conical tube is 5kV, the potential difference between the conical tube and the objective lens is 10kV, and the sample is a single-layer graphene structure grown on the Ru(0001) single crystal surface. Figure 4 The lower curve corresponds to the gray level distribution of the black line area in the figure, and the resulting spatial resolution is about 25nm. This case illustrates that the NAP-PEEM device of the present invention can achieve higher spatial resolution under an atmosphere of 0.12 mbar.

Embodiment 3

[0048] PEEM imaging in a near-atmospheric atmosphere ( Figure 5 ). The nitrogen pressure in the sealed atmosphere chamber is 1.2mbar, and after the gas differential pumping, the pressure of the PEEM imaging chamber is 1.2×10 -5 mbar, the pressure at the detector is 1.2×10 -7 mbar. The potential difference between the sample and the conical tube is 0.3kV, and the potential difference between the conical tube and the objective lens is 5.7kV. The sample is a single-layer graphene structure grown on the Ru(0001) single crystal surface. Figure 5 The lower curve corresponds to the gray level distribution of the black line area in the figure, and the resulting spatial resolution is about 100nm. This case shows that the NAP-PEEM device in the present invention can realize PEEM imaging in a near-atmospheric pressure atmosphere of 1.2 mbar, reaching a spatial resolution of 100 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com