Drain apparatus

A technology of drainage mechanism and strip plate, applied in furnaces, heat treatment equipment, coating of superimposed layers, etc., can solve the problems of strip steel oxidation, refrigerant flowing downward, and insufficient water removal, and achieve the effect of reducing water removal load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

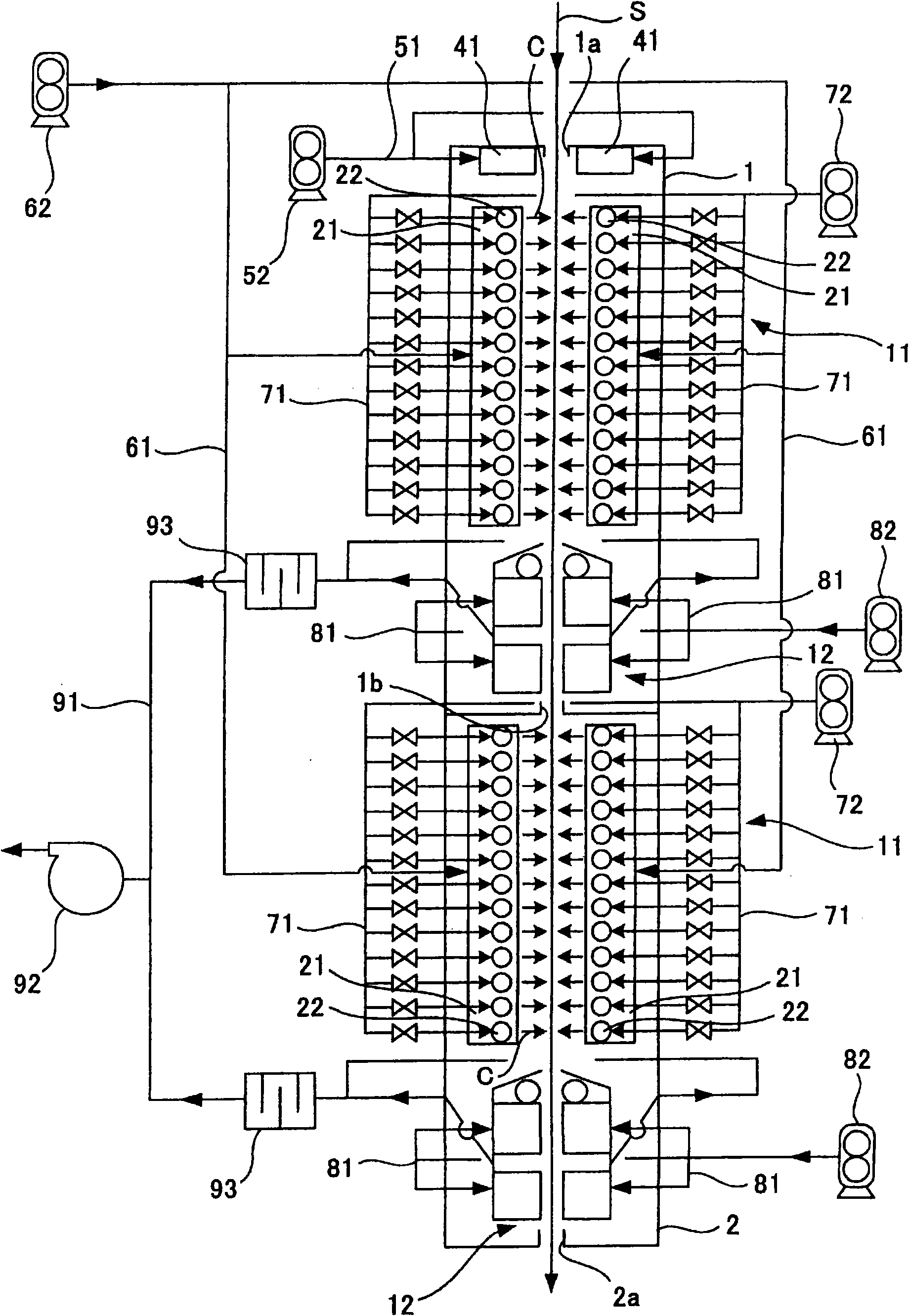

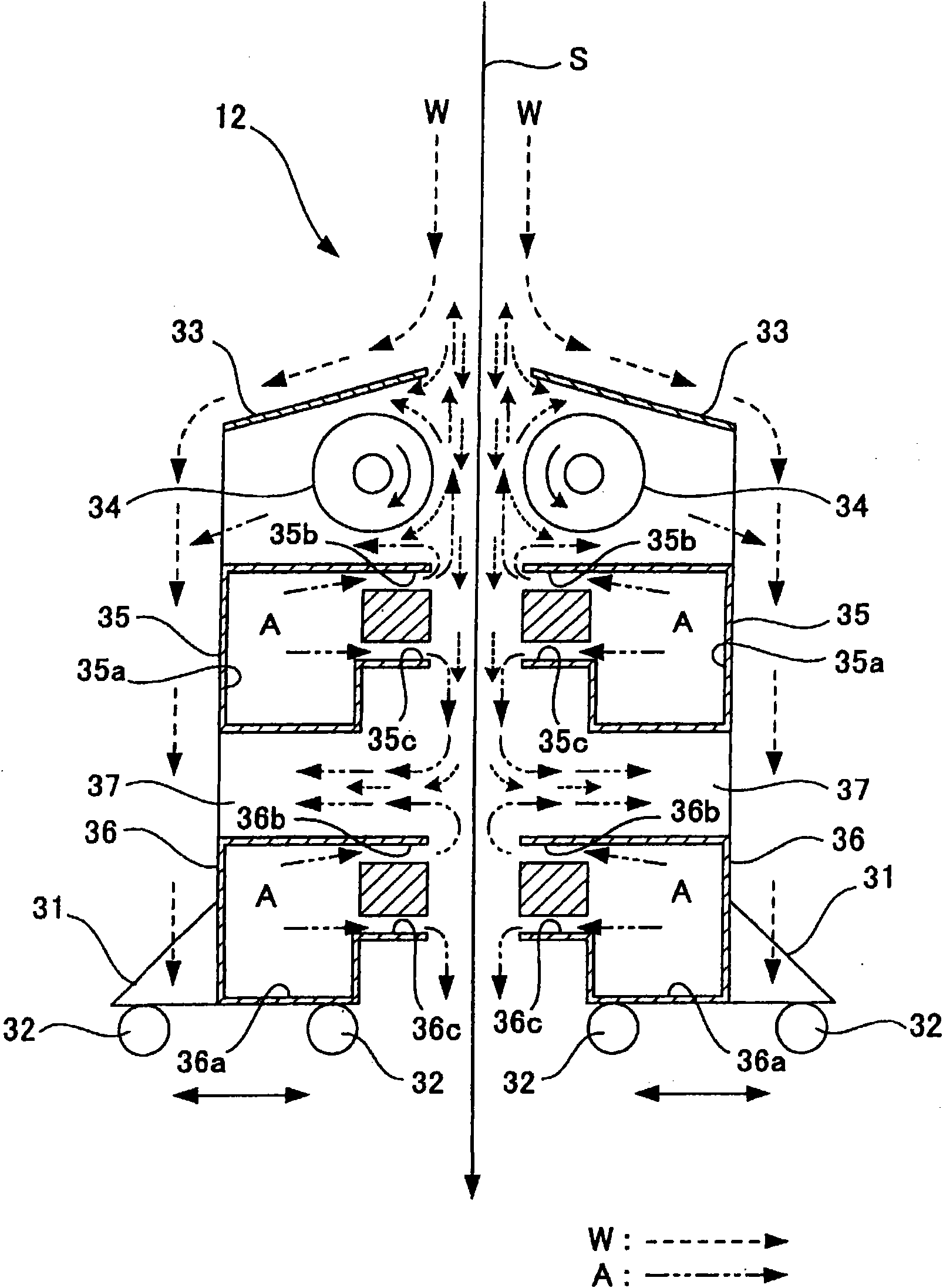

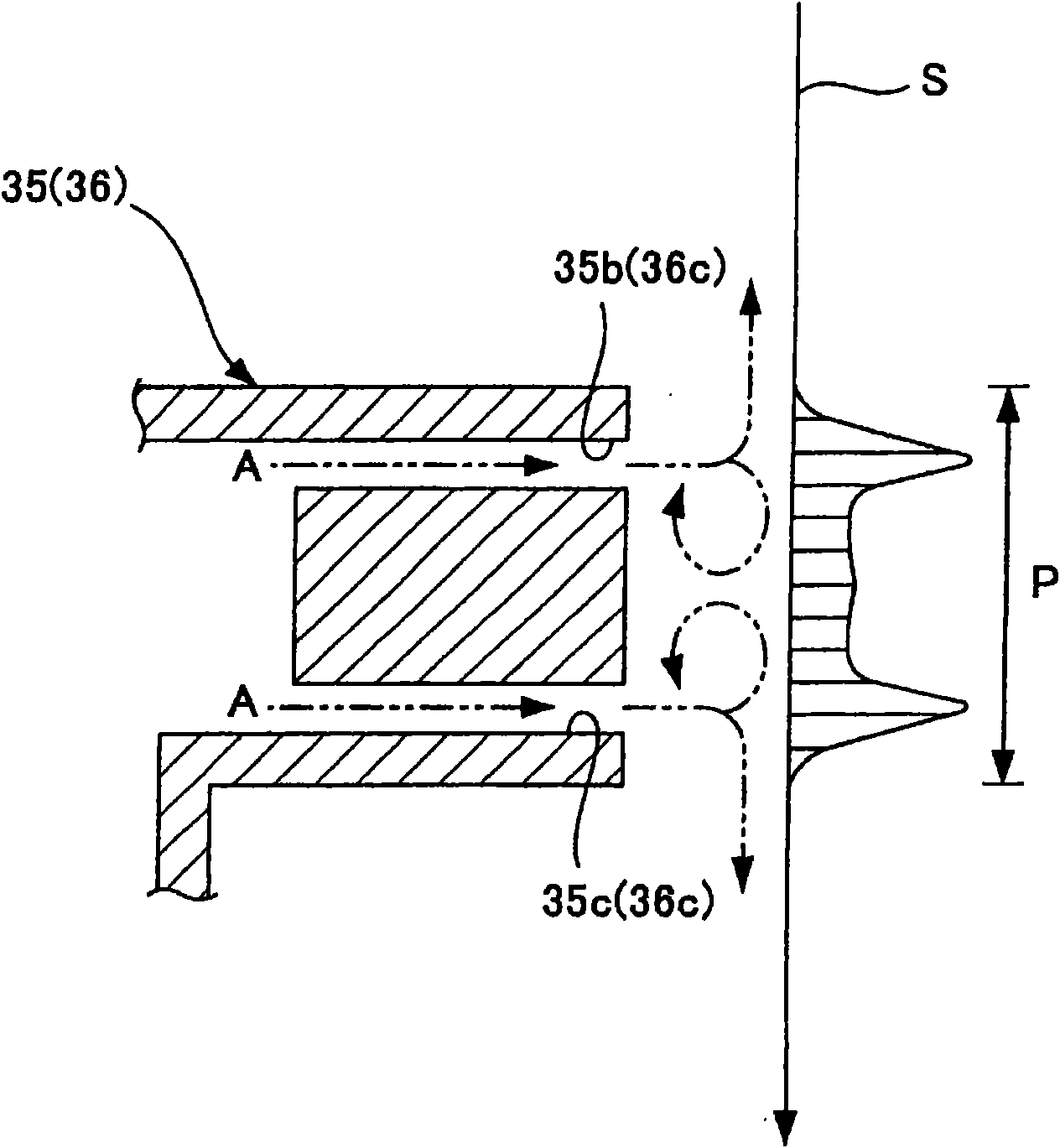

[0022] Next, the dewatering device according to the present invention will be described in detail with reference to the drawings. In addition, this embodiment is an embodiment in which the water removal device according to the present invention is applied to a cooling zone of a continuous annealing facility. figure 1 It is a schematic diagram of a cooling zone of a continuous annealing facility equipped with a water removal device according to an embodiment of the present invention. figure 2 It is a schematic cross-sectional view of the dewatering device according to one embodiment of the present invention. image 3 It is a graph showing the pressure distribution of the steel strip by the air injected by the upper and lower slits of the nozzle.

[0023] Such as figure 1 As shown, in the unshown continuous annealing facility for heat-treating the steel strip S, the primary cooling zone 1 and the secondary cooling zone 2 for cooling the steel strip S are arranged adjacently u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com