Flouring method for aluminum pot and powder manufacturing installation

A manufacturing device and powdering technology, which are applied in the fields of powdering and powder manufacturing of aluminum cans, can solve problems such as ignition and inability to obtain powder, and achieve the effects of maintaining cooling efficiency, small usage and good cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

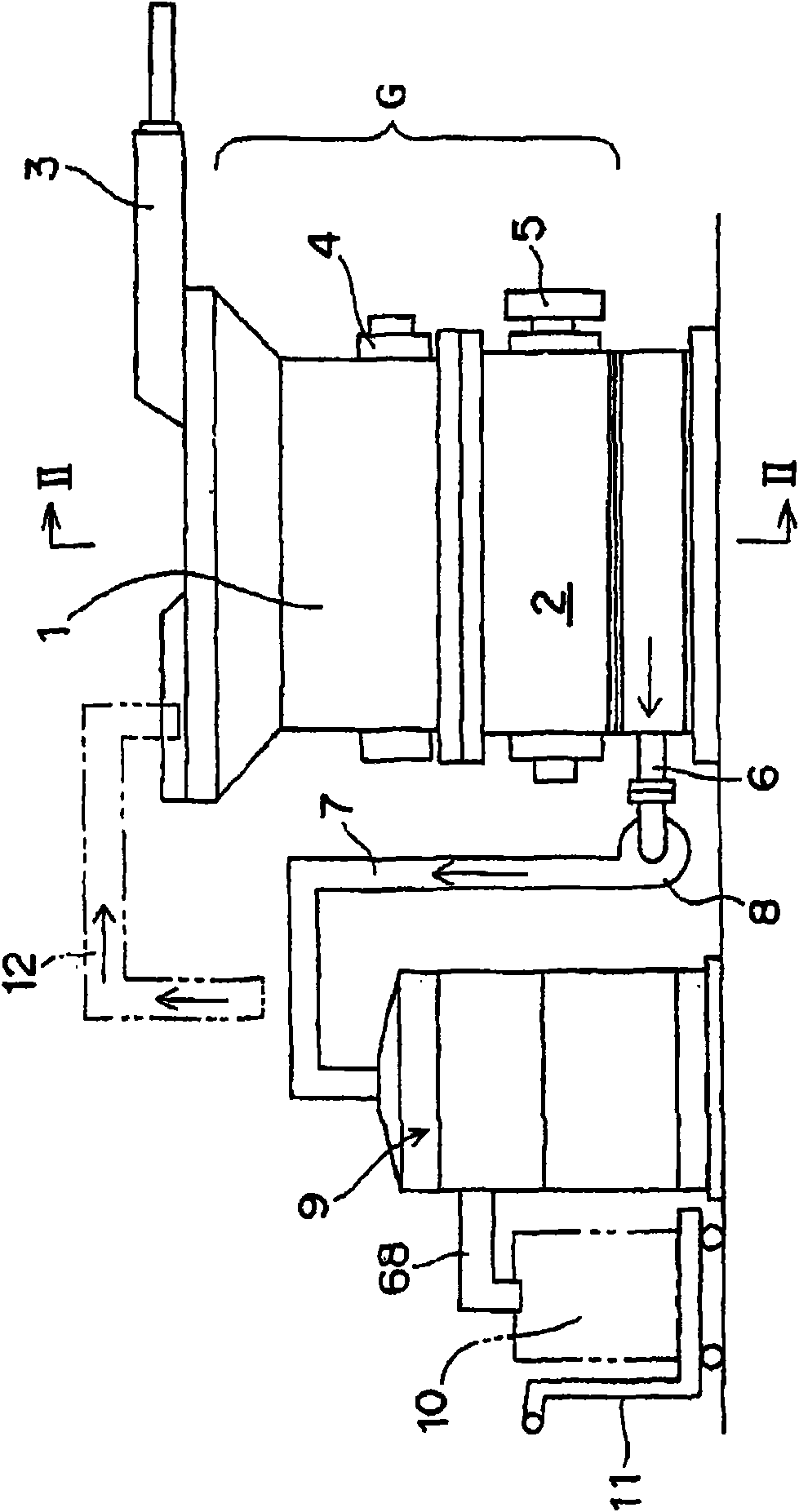

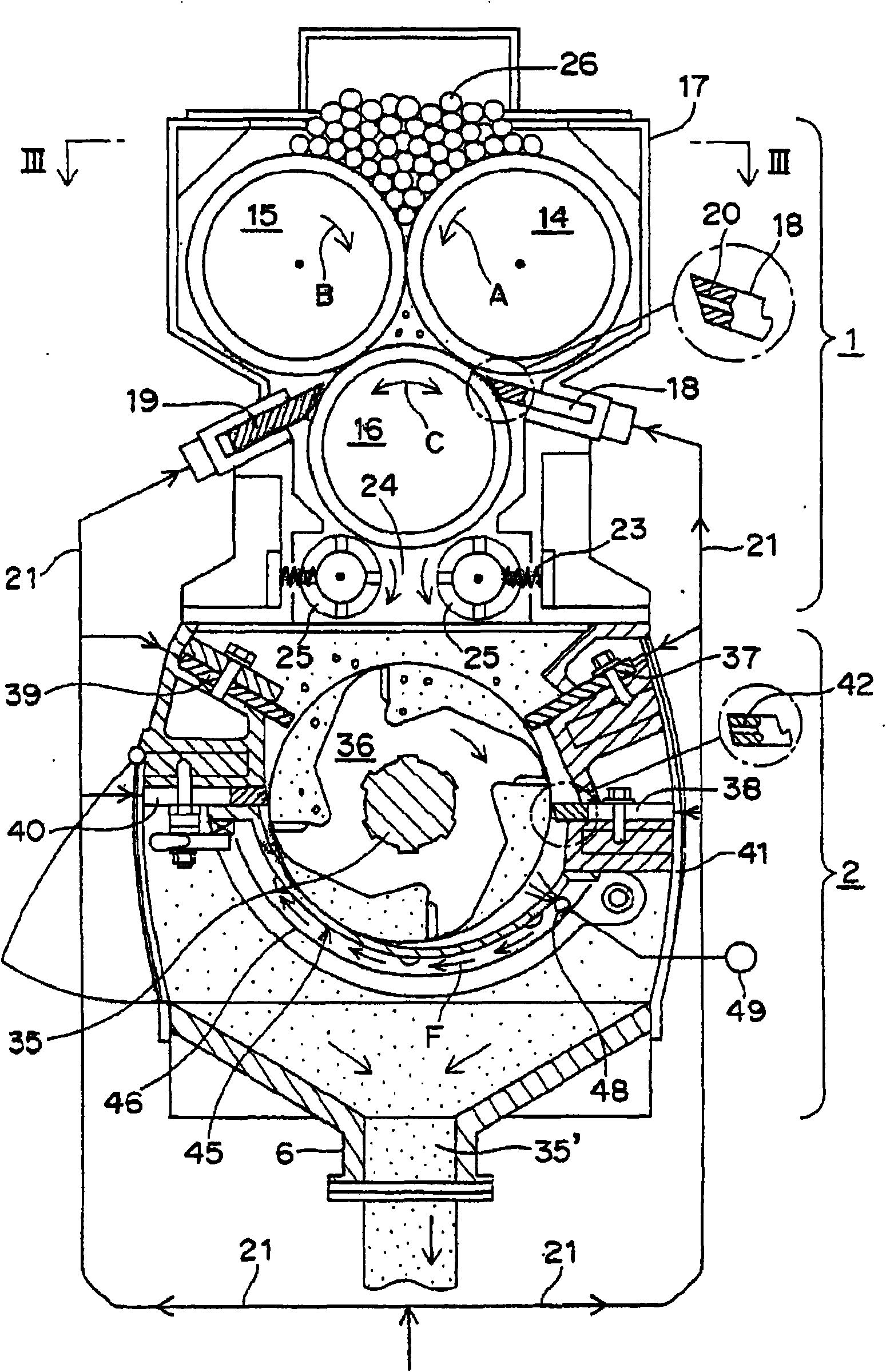

[0040] in positive figure 1 In , it shows an example of the powder manufacturing device G in which the single-shaft pulverizer 2 is integrally assembled on the lower side of the three-shaft pulverizer 1, wherein symbol 3 is an automatic aluminum can insertion device, symbols 4 and 5 are hydraulic motors, and symbols 6 and 7 are delivery pipes, 8 is a pump for suction, 9 is a vibrating sorter, 10 is a container for storing products processed into a state suitable for thermite reaction, and 11 is a trolley. Reference numeral 12 is a return pipe for oversized semi-finished products, and reference numeral 68 is a product discharge port.

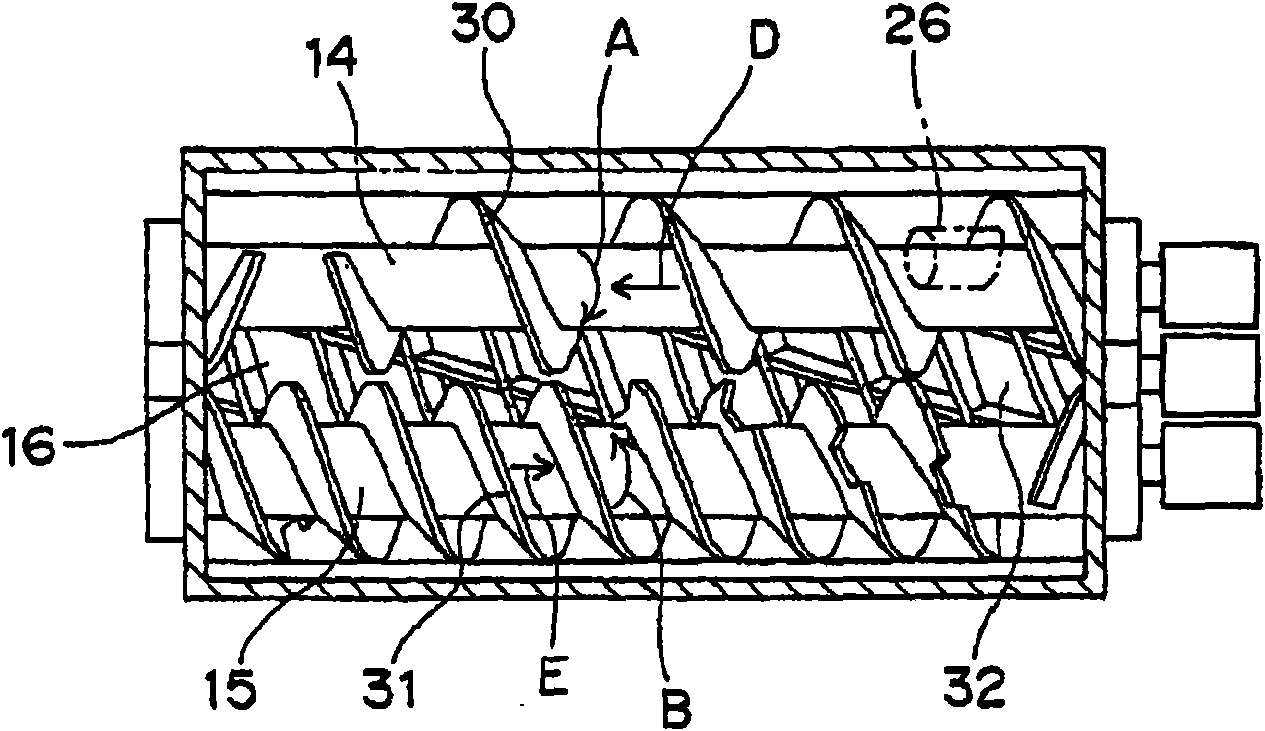

[0041] figure 2 The three-shaft pulverizer 1 (commodity MARIN of the applicant of the present application) includes: two upper screw rods 14, 15 (driven to rotate at a speed of, for example, 5 to 60 rpm in the directions of arrows A and B); a lower screw rod 16 (for example, driven by Driven to rotate freely in the arrow C direction at the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com