Rotary tool turret matching NC turning and milling center and machining method

A rotary turret, turning and milling technology, which is applied in the direction of tool holders, etc., can solve the problems of low rotation accuracy, high cost, and easy loosening of tool holders, and achieve the effects of shortening working time, improving processing efficiency, and maintaining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

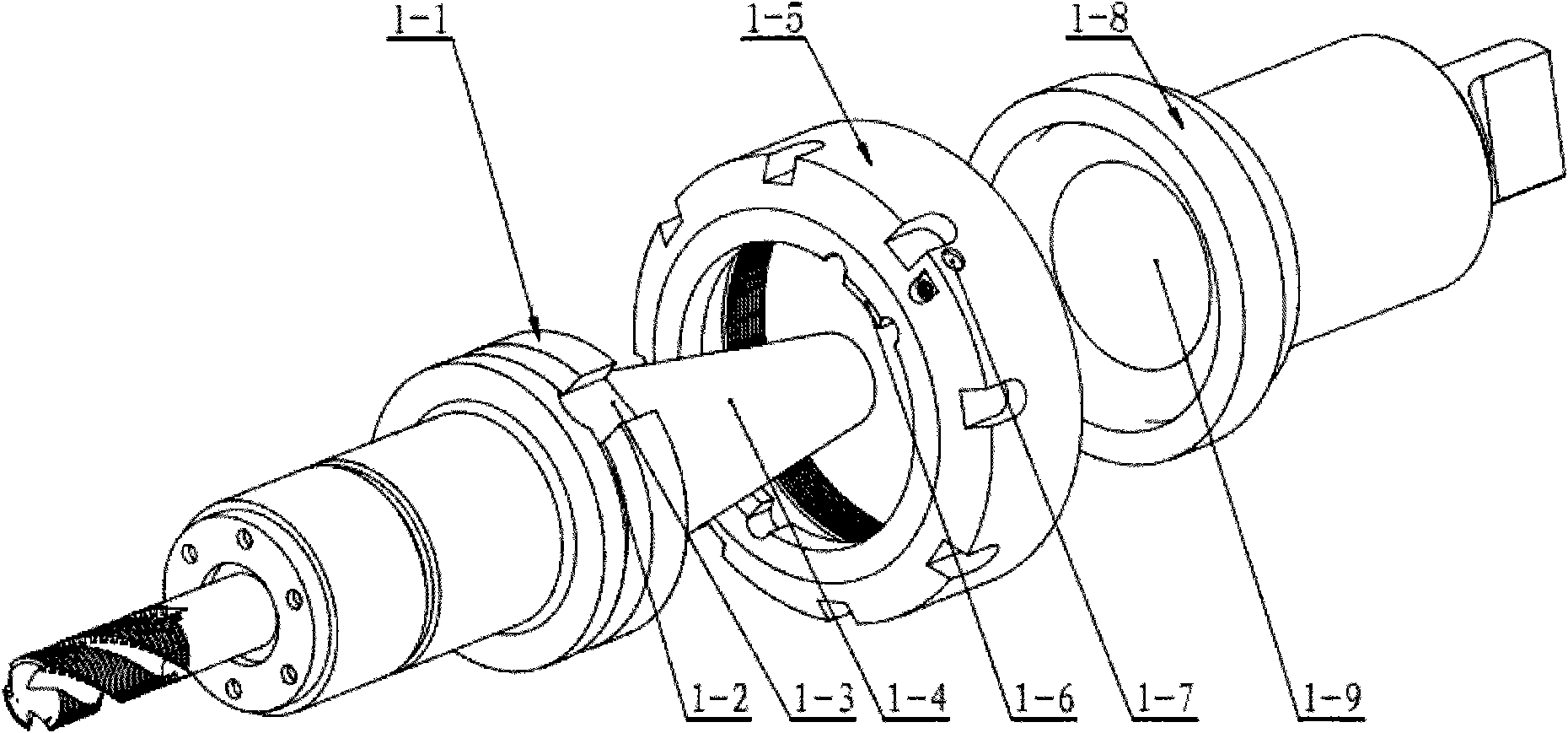

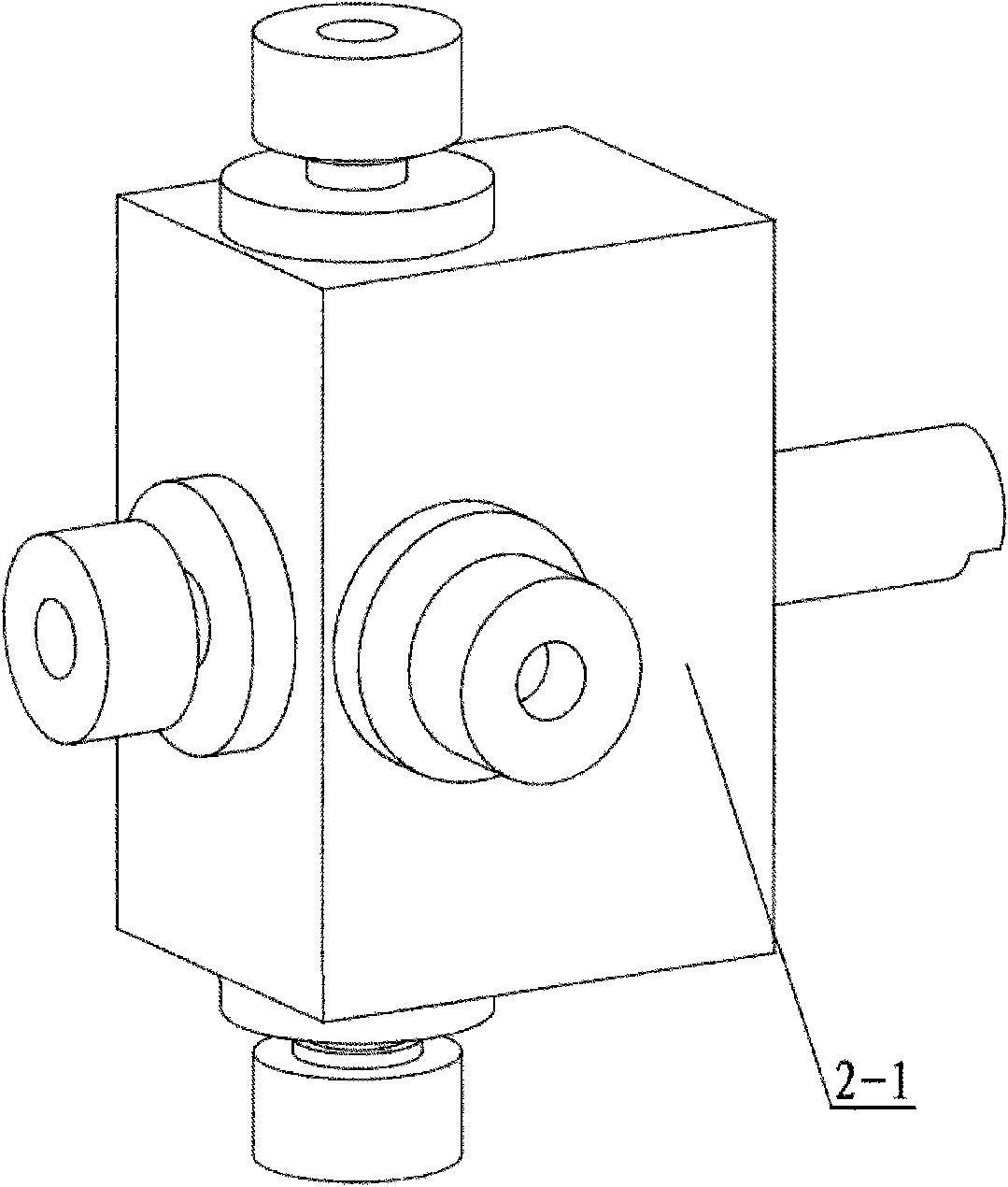

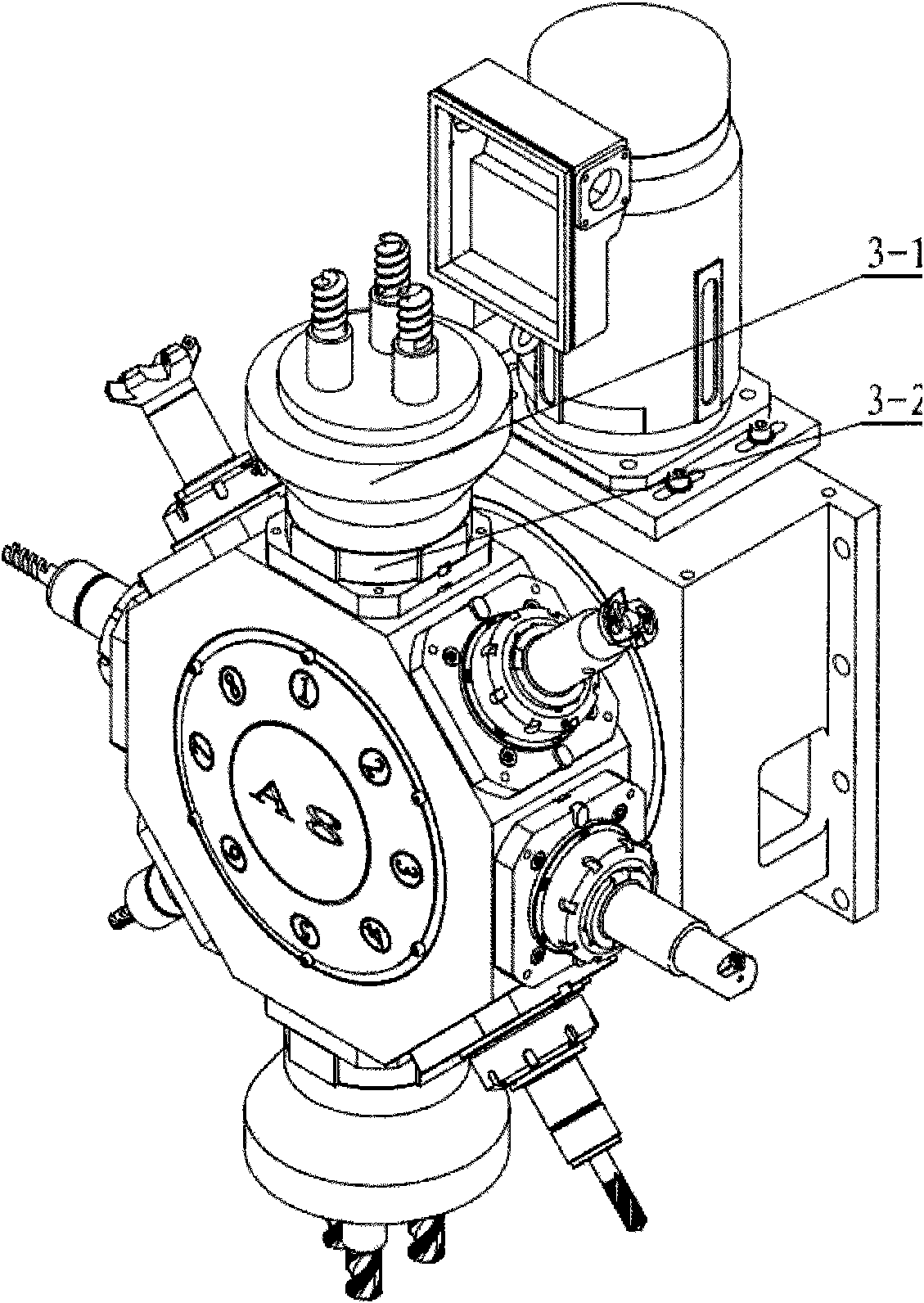

[0016] Embodiment 1: see attached Figure 1 to Figure 5 . A rotary turret matched with a CNC turning and milling center, which includes a turning and milling compound turret, a servo motor 5-16 in the turning and milling compound turret drives a main shaft transmission shaft 5-13 through a transmission mechanism, and the main shaft transmission shaft 5 -13 connection end is in-line groove 4-1 and is mated with in-line flat head tool handle seat 1-8 in-line convex head plug-in matching, drives the cutter on the rotary turret to process, and the in-line flat head in the turret The knife handle seat cooperates with the inline guide groove of the guide seat on the guide seat and rotates along the guide seat. The transmission mechanism drives the main shaft drive shaft 5-13 to rotate through the synchronous belt pulleys 5-14 and 5-17 and the synchronous belt 5-15, and the synchronous belt pulley 5-14 is fixed on the main shaft transmission shaft 5-13, and the synchronous belt whee...

Embodiment 2

[0026] Embodiment 2: On the basis of Embodiment 1, a method of rotating a rotary turret matched with a CNC turning and milling center, the servo motor 16 drives the transmission mechanism, the transmission mechanism drives the main shaft transmission shaft 5-13, and the main shaft transmission shaft 5- The inline groove at the end of 13 is plugged with the inline flat head handle seat 1-8 at the end and drives the inline flat head handle seat 1-8 to rotate, and the rotation of the turret drives the inline flat head knife The handle seat rotates 360 degrees circularly with the inline guide groove of the guide seat. After the turret rotates at a specific angle, the inline flat end of the inline flat head tool handle seat is transferred into the inline groove of the main shaft drive shaft and matched. Drive the spindle transmission shaft to rotate through the servo motor, so that the flat-shaped tool handle seat rotates, and at this time, the tool can be placed in the flat-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com