Heat exchanger cooling tube and tube plate bimetal welding technology

A technology of welding process and cooling pipe, applied in the direction of metal processing equipment, welding medium, welding equipment, etc., can solve the problems of unguaranteed quality, long manufacturing cycle, high cost, etc., and achieve the effect of reducing manufacturing cost and production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

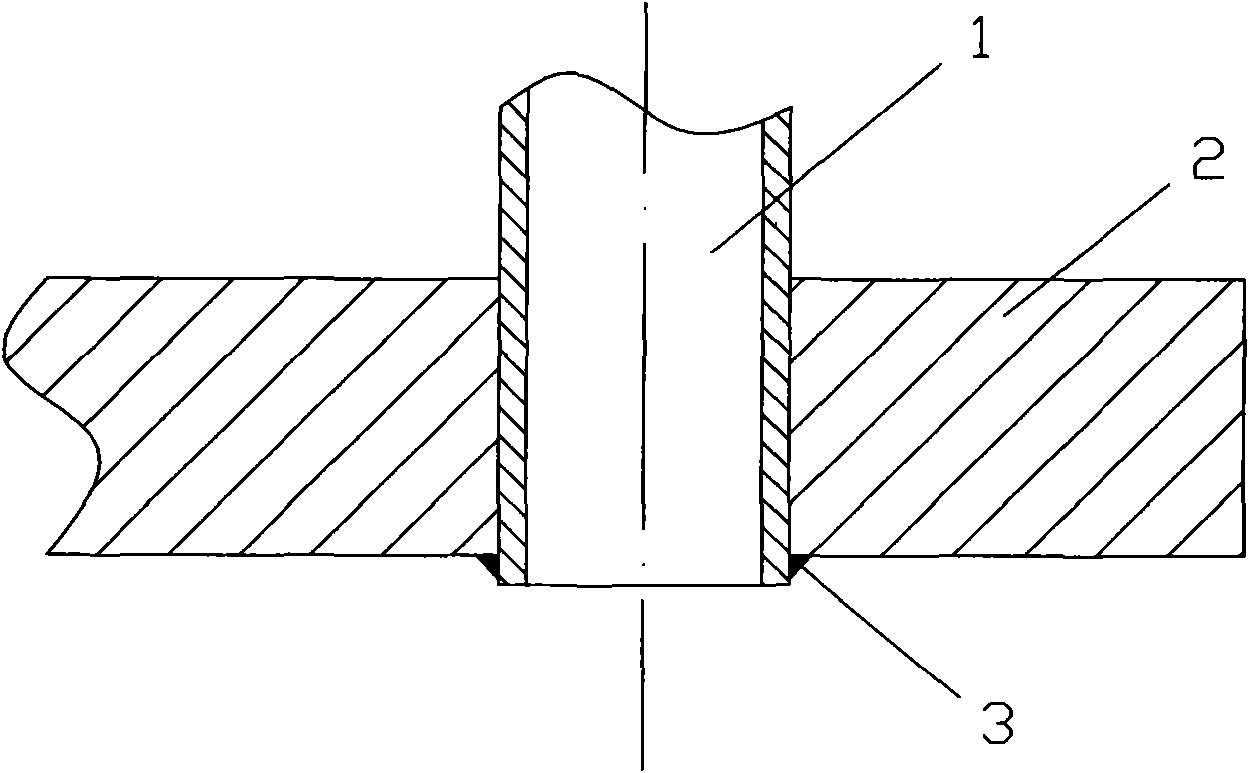

[0008] Referring to the accompanying drawings, the NiCu alloy is used to make the cooling pipe 1, and the simple CS carbon steel is used to make the tube sheet 2, and the NiCu cooling pipe 1 is inserted on the CS tube sheet 2, and the connection part (welding) 3 of the tube head and the tube sheet For welding, the welding process selects BFe10-1-1 argon arc welding wire with a diameter of φ0.8mm, uses an argon arc automatic welding machine, sets the current at 60-120A, and welds at a welding speed of 75mm / min. After adopting the process of the invention to weld the different metals of the cooling pipe and the tube plate, a high-quality formed weld seam can be formed, the non-destructive inspection has no defects, and the tensile strength meets the requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com