Structure self-heat-insulation concrete wall plate and manufacture method thereof

A production method and self-insulation technology, which is applied to walls, building components, building structures, etc., can solve the problems of prolonging the construction period, different elastic modulus and linear expansion coefficient, and poor durability, so as to prolong the service life and reduce the The effect of post-maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

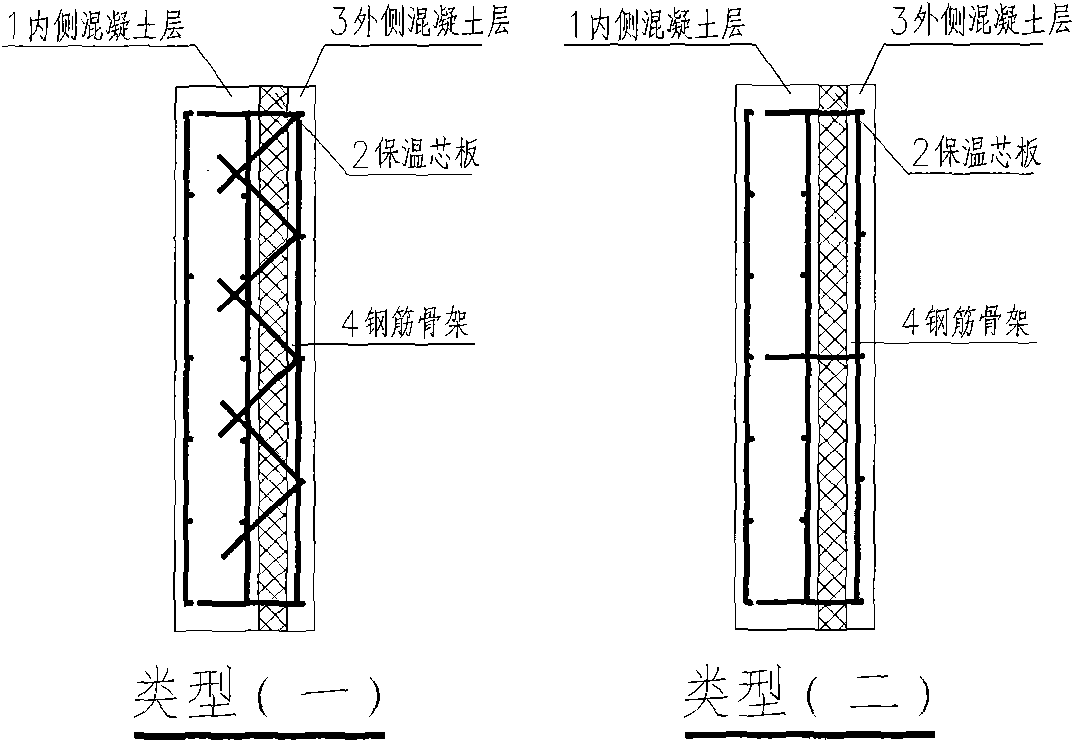

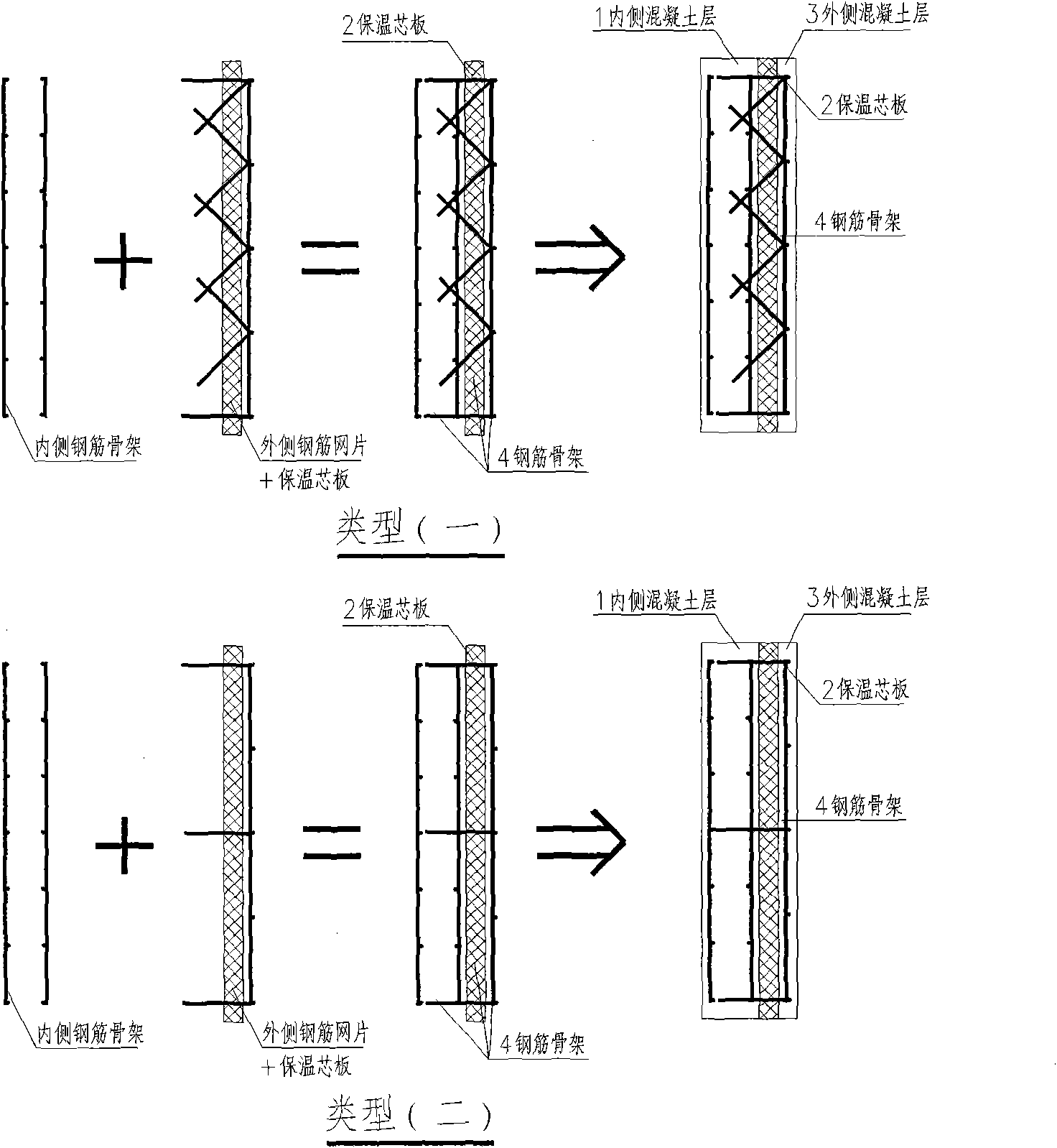

[0024] According to the effect of the outer concrete layer, the present invention divides the composite wall panels into two categories:

[0025] Type (1): As part of the shear wall on the outside, the composite wall panel can not only meet the building energy-saving design standards, but also ensure that the concrete layers on both sides work together. The content of oblique steel bars is determined comprehensively by thermal performance and cooperative work. The content is generally 0.03-0.06%, and the angle between the oblique steel bars and the horizontal direction is 30°-60°.

[0026] Type (2): The outer concrete layer only protects the insulation core board, and its connection with the inner concrete layer is generally about 0.01% through the tie bars passing through the insulation core board, and its "thermal bridge" effect Can be ignored, the angle between the oblique reinforcement and the horizontal direction is 0°~5°.

[0027] Such as figure 1 As shown, the structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com