Method for acquiring characteristic parameters of displacement control mechanism of hydraulic pump and detection device

A technology of control mechanism and characteristic parameters, applied in pump control, fluid pressure actuation device, pump test, etc., can solve problems such as difficulty in evaluating the accuracy and reliability of results, avoid high cost, high measurement accuracy, measurement accuracy, etc. Good real-time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

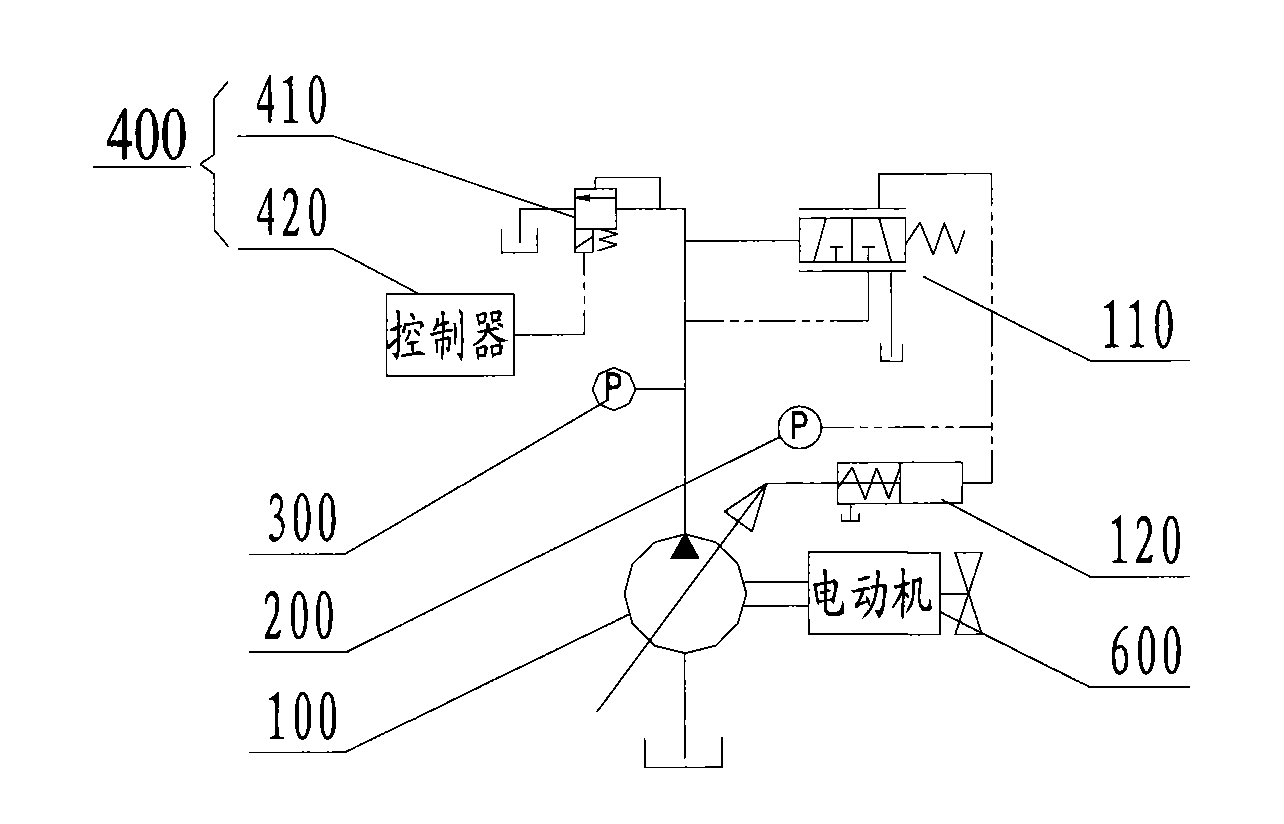

[0047] The detection device of the hydraulic pump displacement control mechanism provided in Embodiment 1 includes a prime mover 600, a loading device 400, a first pressure detection device 200 and a second pressure detection device 300; the figure also shows the hydraulic pump 100 to be tested, The hydraulic pump 100 has a displacement control mechanism 110 and a variable mechanism 120, the input end of the displacement control mechanism 110 communicates with the outlet of the hydraulic pump, and the output end communicates with the variable mechanism 120; the prime mover 600 is used to drive the hydraulic pump 100 to run The loading device 400 is connected to the outlet of the hydraulic pump to form the load of the hydraulic pump 100; the first pressure detection device 200 and the second pressure detection device 300 are respectively connected to the output end of the displacement control mechanism 110 and the hydraulic pump The outlets are connected to detect the pressure a...

Embodiment 2

[0058] The detection device of the hydraulic pump displacement control mechanism provided in the second embodiment includes: a prime mover 600, a loading device 400, a first pressure detection device 200 and a second pressure detection device 300; oscilloscope 500, and use pressure sensors as the first pressure detection device 200 and the second pressure detection device 300. The wave recorder 500 is connected to the first pressure detection device 200 and the second pressure detection device 300 respectively; the first pressure detection device 200 and the second pressure detection device 300 transmit pressure signals to the wave recorder 500 while detecting pressure.

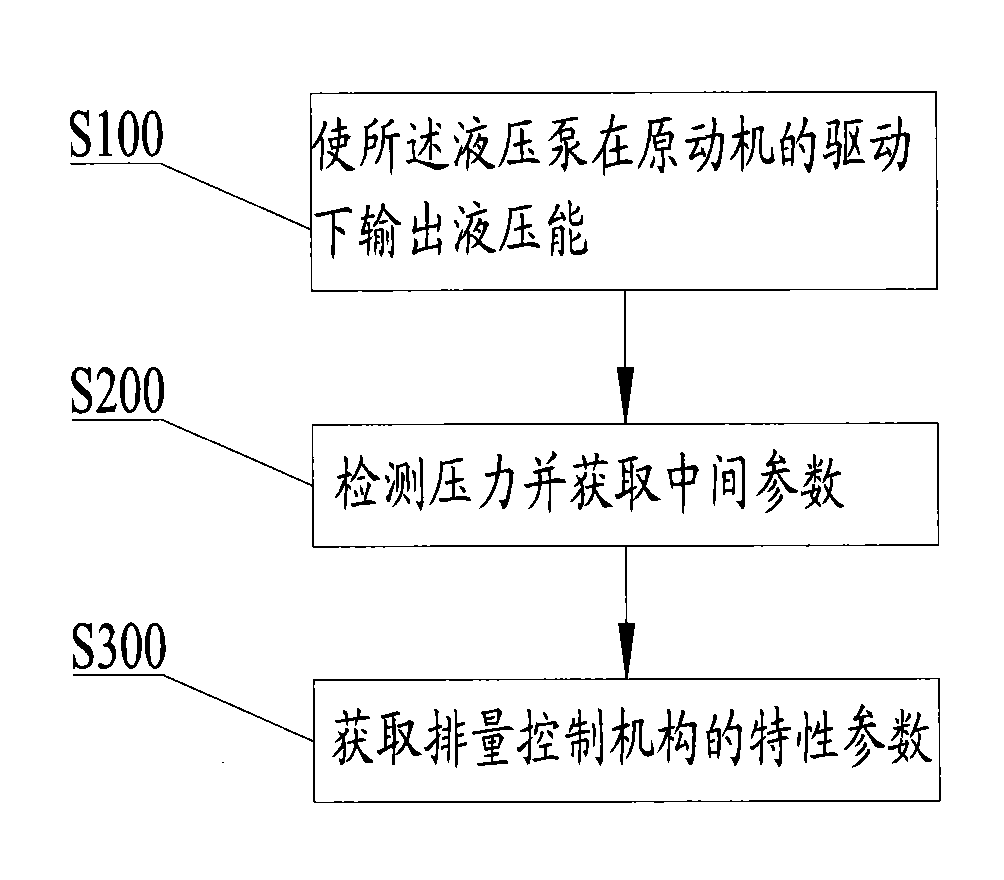

[0059] Such as Figure 5 As shown, this figure is a flow chart of a method for obtaining the characteristic parameters of the displacement control mechanism 110 by using the detection device of the hydraulic pump displacement control mechanism provided in the second embodiment. The method includes the followi...

Embodiment 3

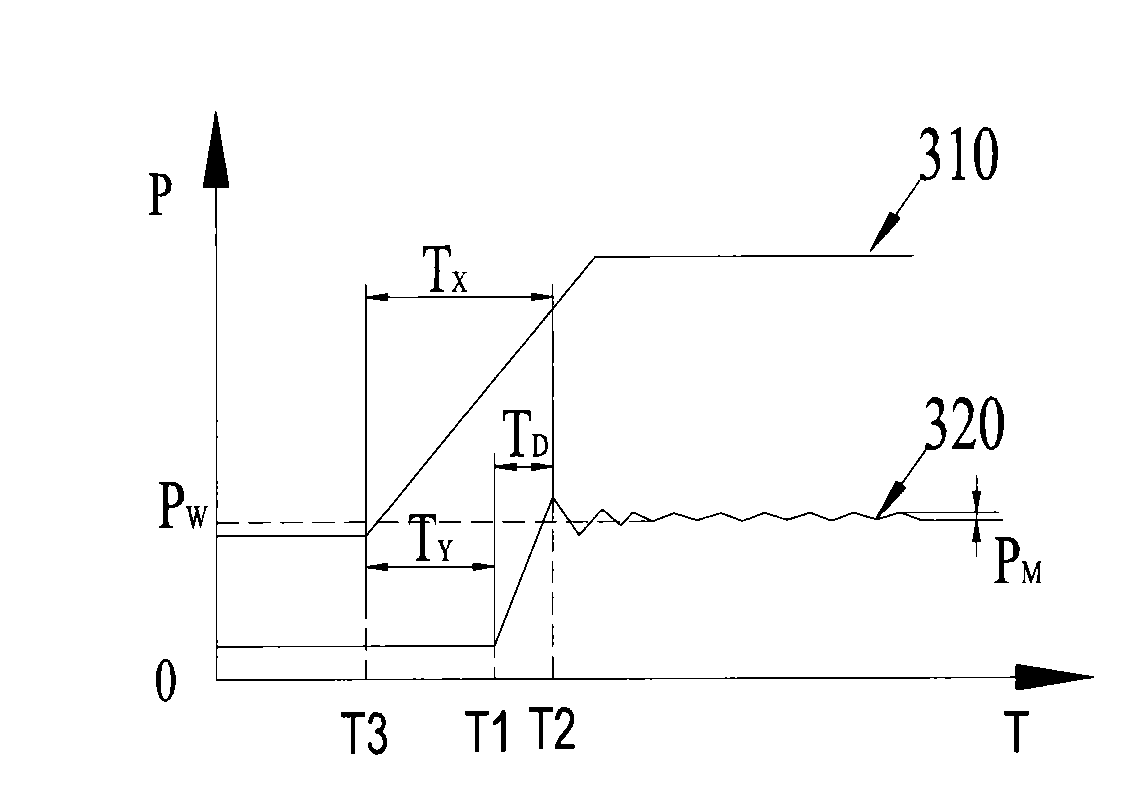

[0066] The detection device of the hydraulic pump displacement control mechanism provided in Embodiment 3 includes a prime mover 600, a loading device 400, a wave recorder 500 and a first pressure detection device 200. In this example, the detection device of the hydraulic pump displacement control mechanism Only the first pressure detection device 200 is included, and other structures are the same as the detection device of the hydraulic pump displacement control mechanism provided in the second embodiment. In this way, according to the pressure signal output by the first pressure detection device 200, the wave recorder 500 can only generate the pressure time-domain waveform diagram of the output of the displacement control mechanism 110, please refer to Figure 7 , which is a time-domain waveform diagram of the pressure at the output end of the displacement control mechanism obtained by the detection device of the hydraulic pump displacement control mechanism provided in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com