Converter for low-voltage traversing double-fed wind driven generator

A wind turbine and low-voltage ride-through technology, which is applied in the field of wind turbine converters and doubly-fed wind generator converters, can solve the problems of long operation period, increased protection measures, and increased equipment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

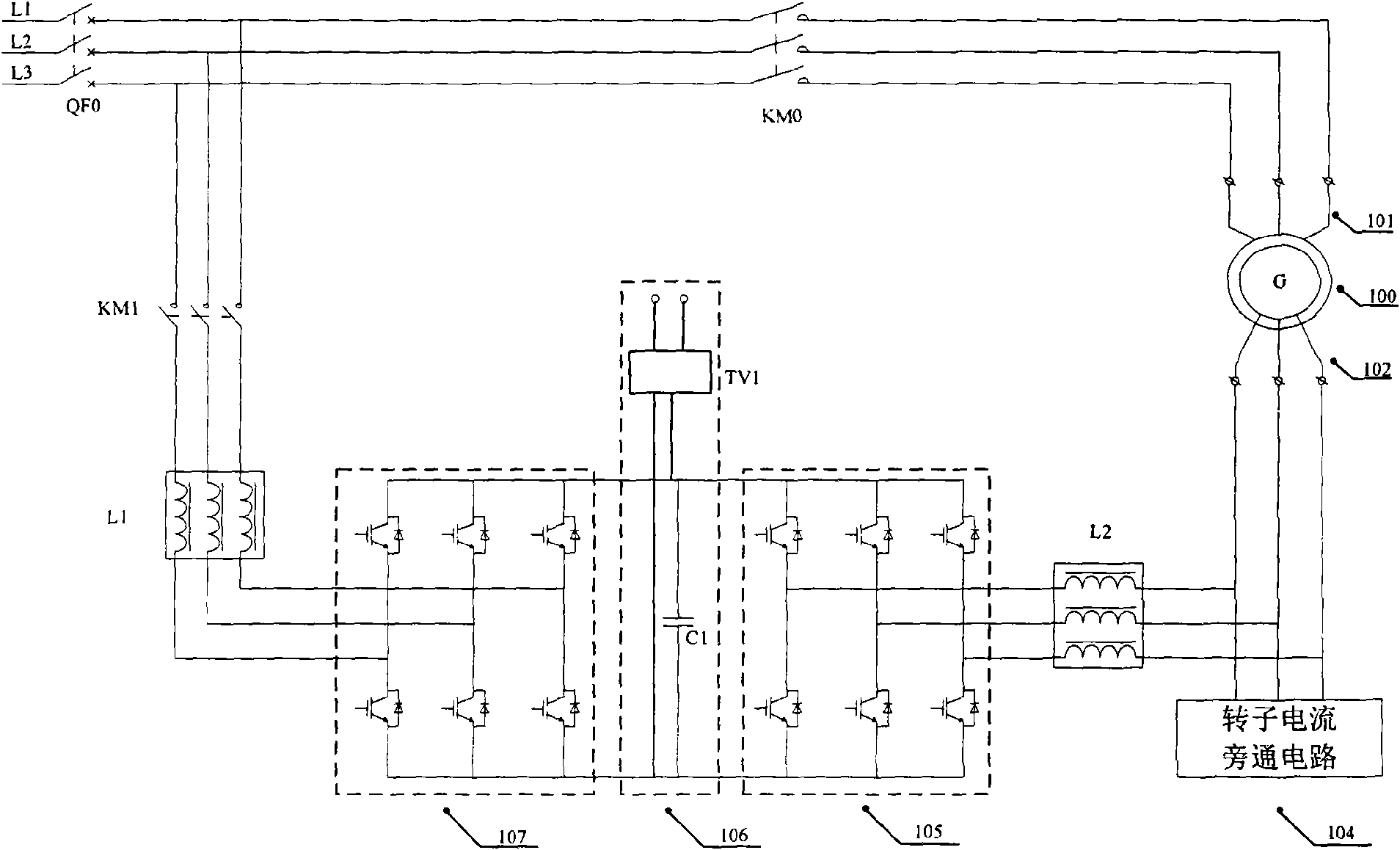

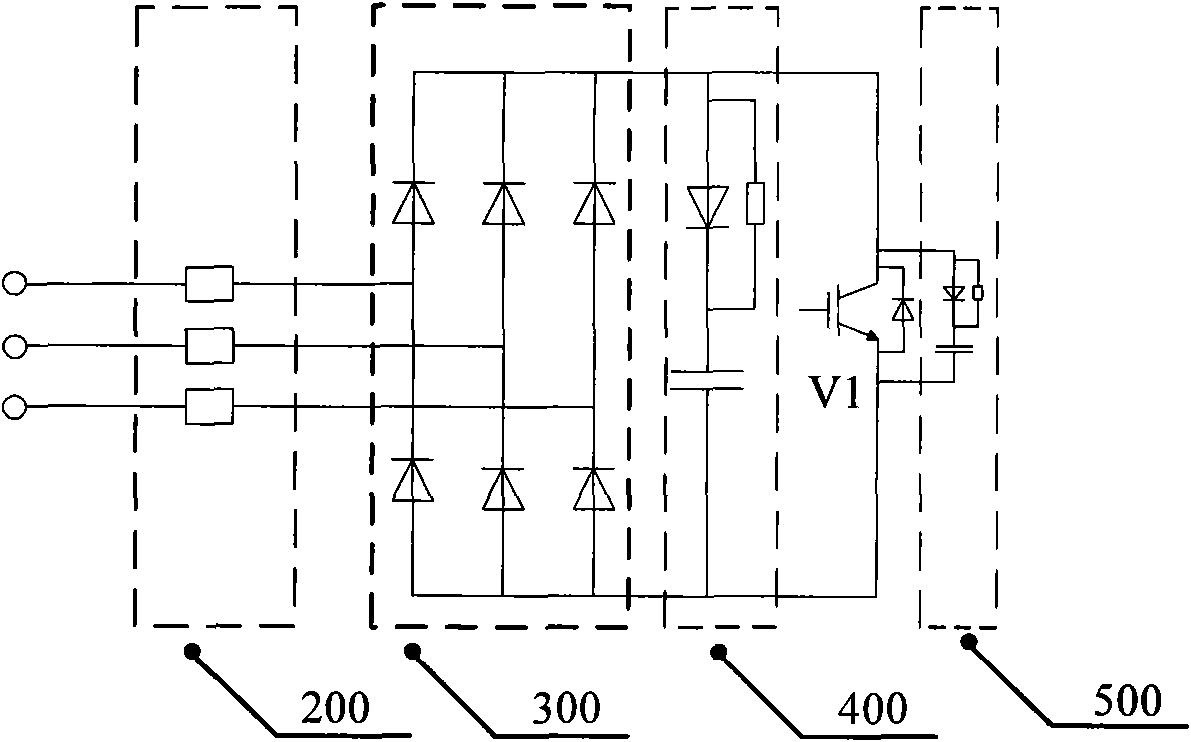

[0027] figure 1 It is a schematic diagram of a generator system composed of a low-voltage ride-through type doubly-fed wind power generator converter and a doubly-fed induction wind power generator of the present invention. As shown in the figure, the doubly-fed induction wind generator 100 is composed of a stator 101 and a rotor 102 . The low-voltage ride-through double-fed wind turbine converter includes: stator-side grid-connected switch KM0, rotor-side filter L2, rotor-side converter 105, intermediate DC link 106, grid-side converter 107, and grid-side rectification reactance L1, grid side grid switch KM1.

[0028] Wherein, the stator 101 is connected to the grid through the grid-connected switch KM0 on the stator side. The rotor 102 is sequentially connected to the power grid through the rotor-side filter L2, the rotor-side converter 105, the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com