Line heat source

A wire heat source, wire-shaped technology, applied in the direction of electric heating device, heating element material, heating element shape, etc., can solve the problems of low strength of carbon fiber paper, high density and heavy weight of carbon fiber paper, and achieve high electrothermal conversion efficiency and heat exchange. The effect of high speed and low thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

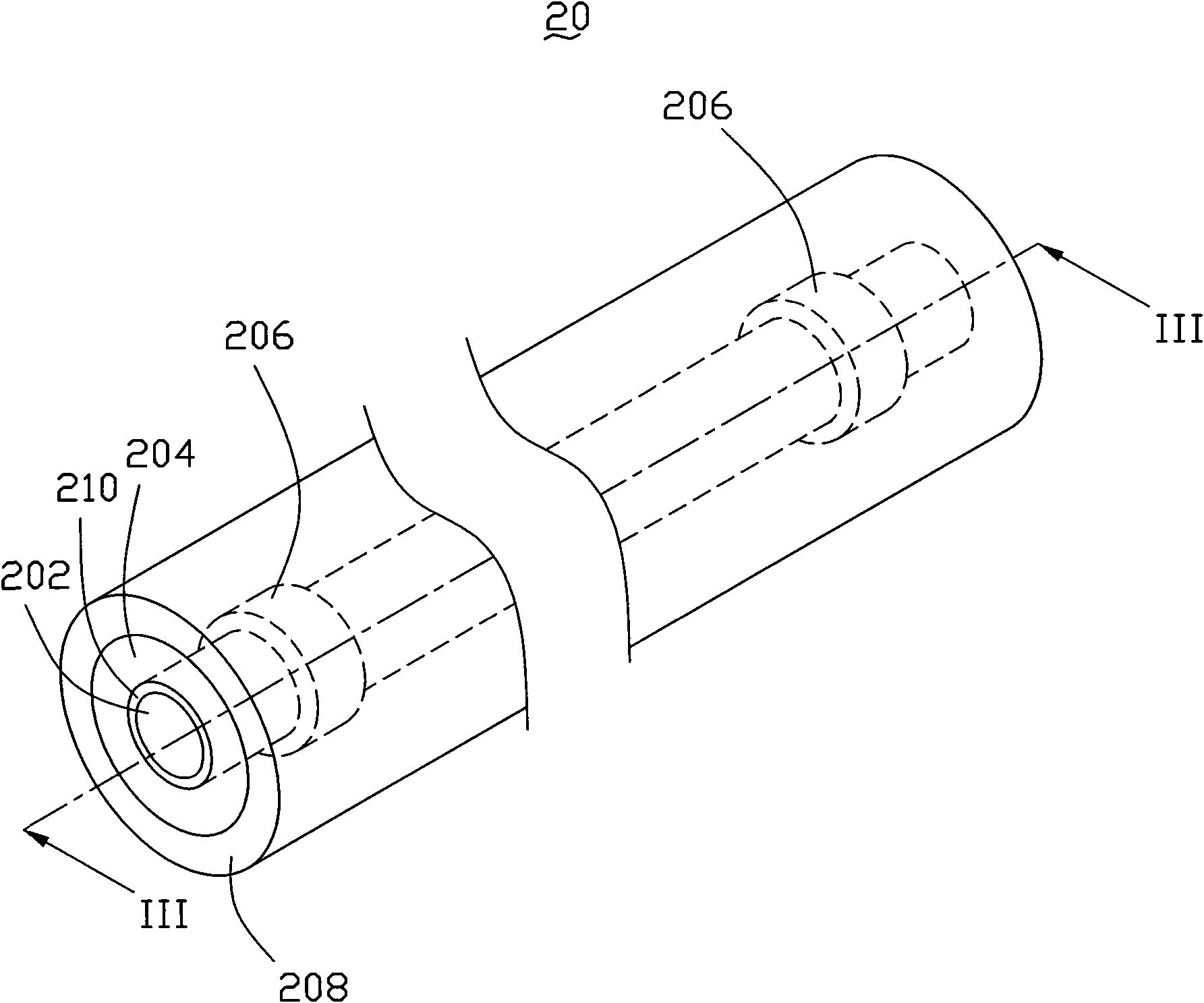

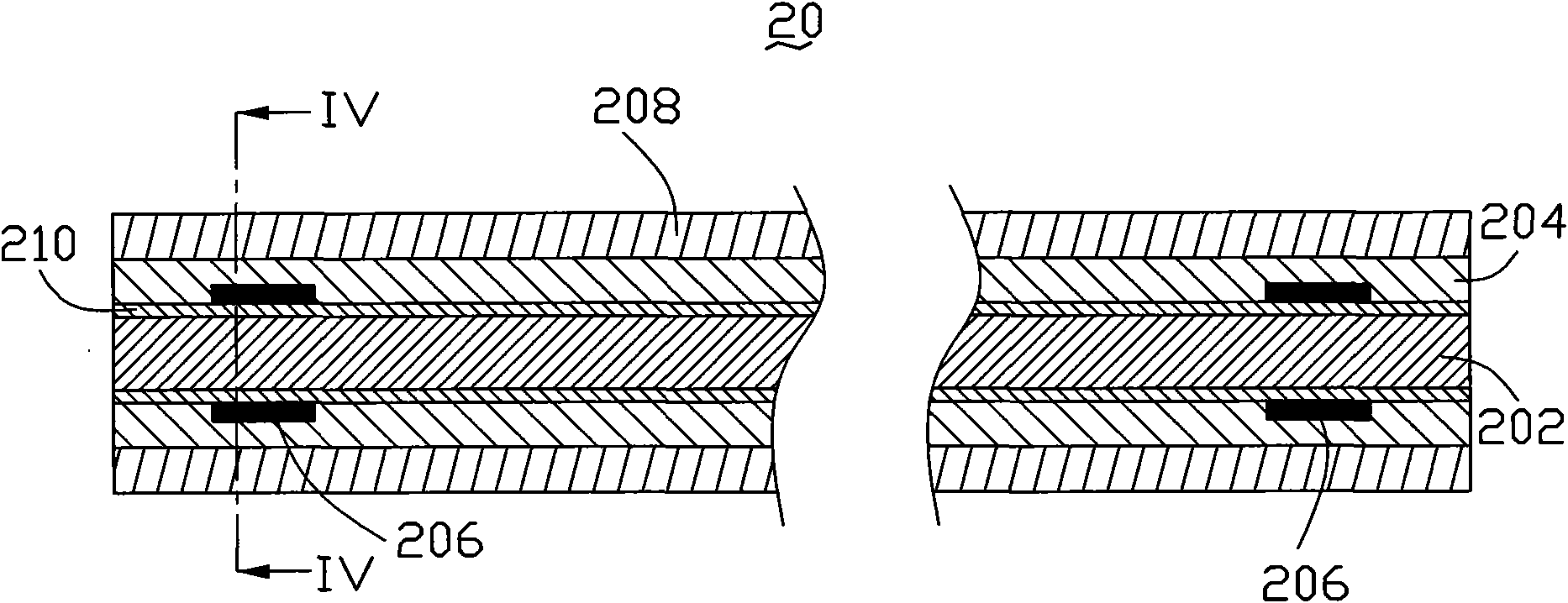

[0017] The linear heat source provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0018] see Figure 2 to Figure 4 , the embodiment of the present invention provides a linear heat source 20, the linear heat source 20 includes a linear support structure 202; a reflective layer 210 is disposed on the surface of the linear support structure 202; a heating element 204 is disposed on the surface of the reflective layer 210 ; two electrodes 206 are arranged at intervals and electrically connected with the heating element 204 ; and an insulating protection layer 208 is arranged on the surface of the heating element 204 . The length and diameter of the wire heat source 20 are not limited. Preferably, the diameter of the wire heat source 20 is 0.1 micron to 1.5 cm. The diameter of the linear heat source 20 in this embodiment is 1.1 millimeters to 1.1 centimeters.

[0019] The linear support structure 202 is used to suppor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com