Sublimation banner thermal transfer ribbons (TTR) and preparation method thereof

A banner carbon ribbon and thermal sublimation technology, applied in the direction of ink ribbon, printing, inking device, etc., can solve the problems of high investment in equipment, slow production speed, limited use area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

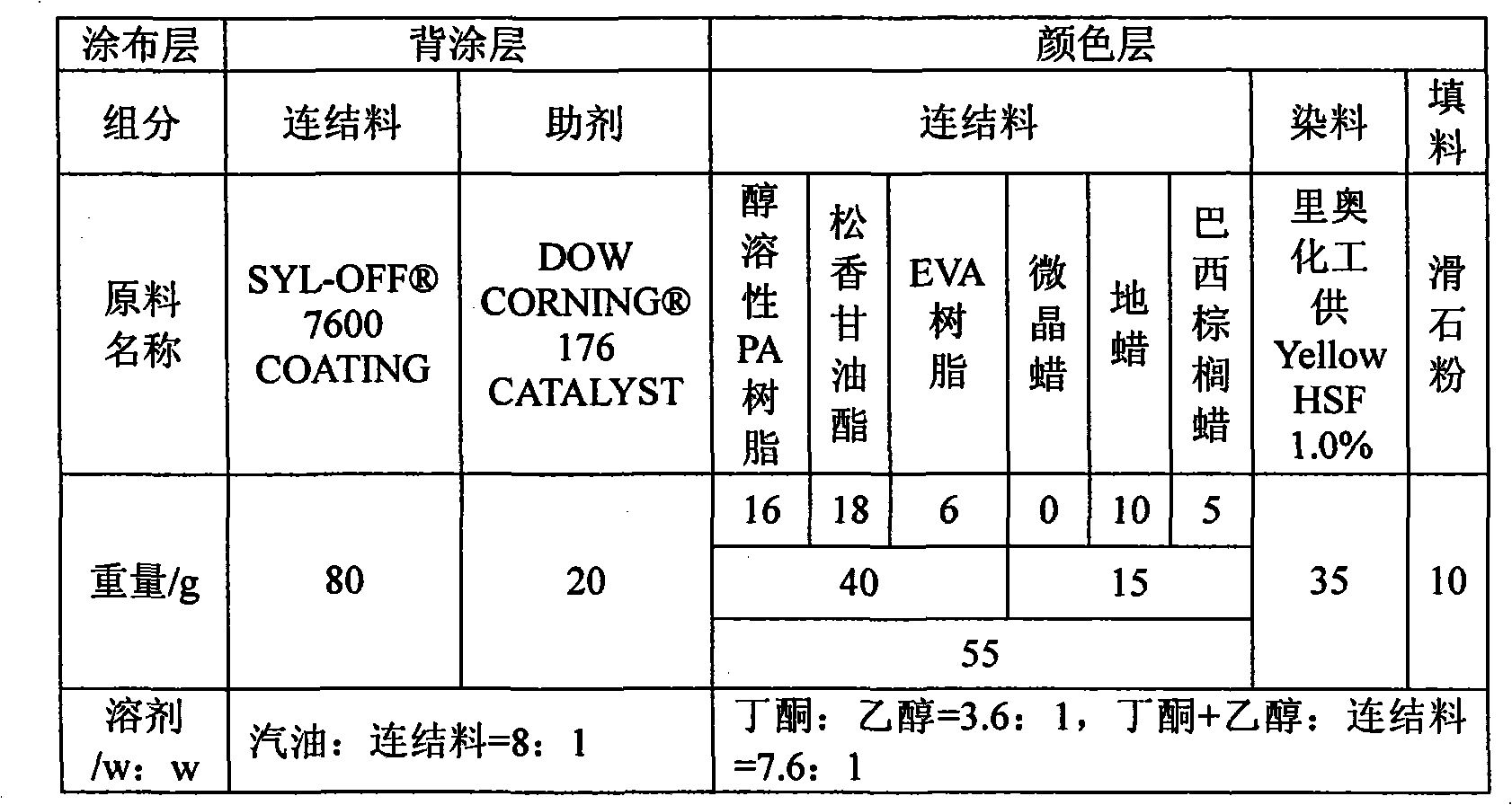

Embodiment 1

[0046]

[0047] making process:

[0048] a. Dilute and mix the binder of the back coating with gasoline (without heating), add additives in proportion 30 minutes before use and mix evenly to form a back coating ink, which is coated on the surface of the tape base with a thickness of 4 μm. Dry at 30°C to form a back coating and enter the next process, requiring the thickness of the layer to be 0.1 μm;

[0049] b. First, mix methyl ethyl ketone and ethanol by weight ratio to obtain a mixed solvent, dissolve the binder of the color layer with the mixed solvent of methyl ethyl ketone and ethanol (temperature 58°C), then add fillers and dyes in proportion, grind to make a color layer For ink, it is required that the dyes should be dispersed evenly and the fineness should be less than 5 μm. They should be coated on the other side of the base and dried at 78°C to form a color layer. The thickness of this layer should be 5 μm. μm, that is to form the thermal sublimation banner rib...

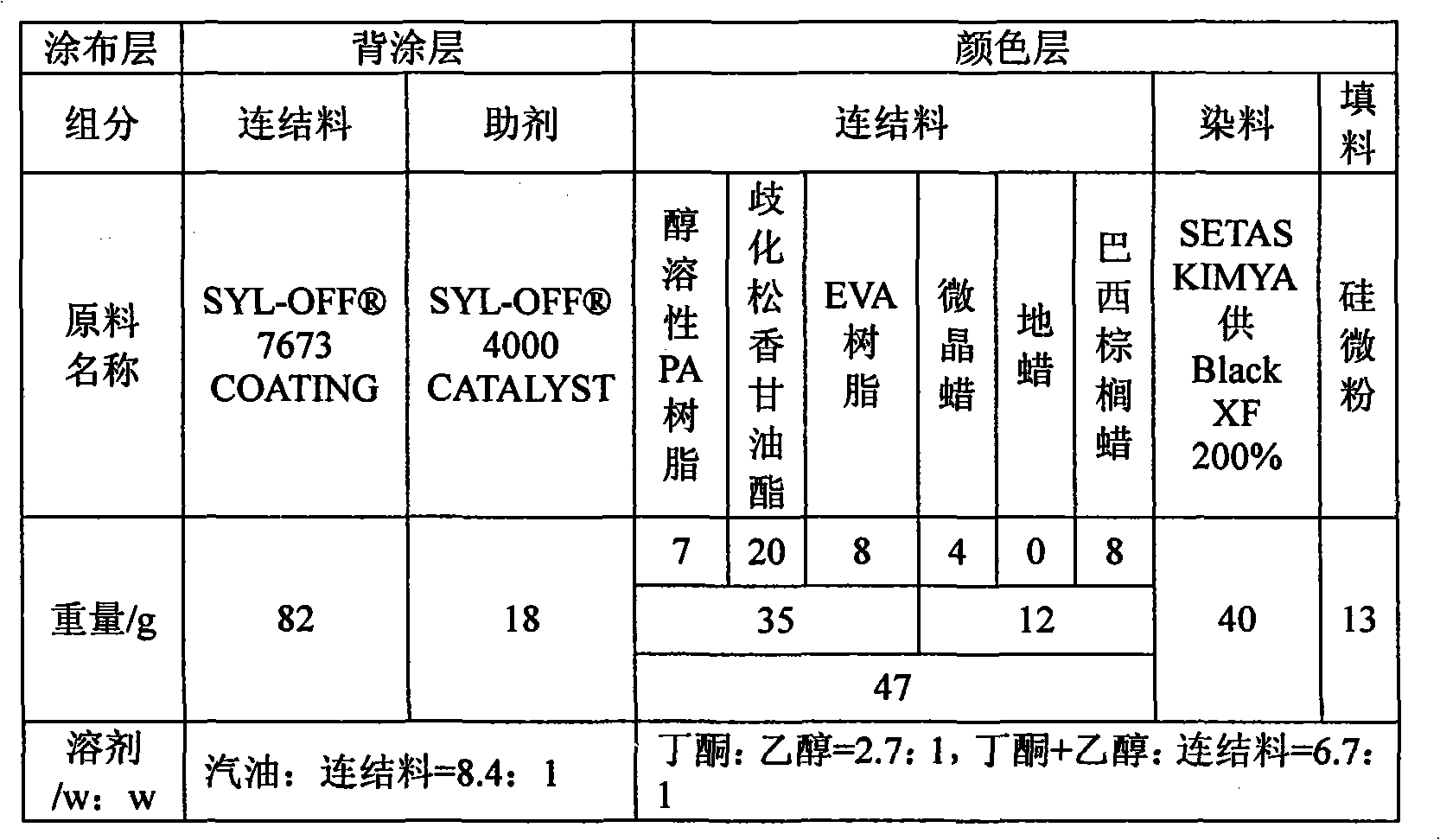

Embodiment 2

[0051]

[0052] Preparation process: After diluting and mixing the binder of the back coating with gasoline in step a, add additives in proportion and mix evenly 35 minutes before use, the drying temperature is 31°C, the thickness of the tape base is 4.2 μm, and the thickness of the back coating is 0.3 μm ; In step b, the melting temperature is 56°C, the drying temperature is 73°C, and the thickness of the color layer is 6 μm; the others are the same as in Example 1, and the total thickness of the obtained thermal sublimation banner printing ribbon suitable for low-speed transfer printing is 10.5 μm.

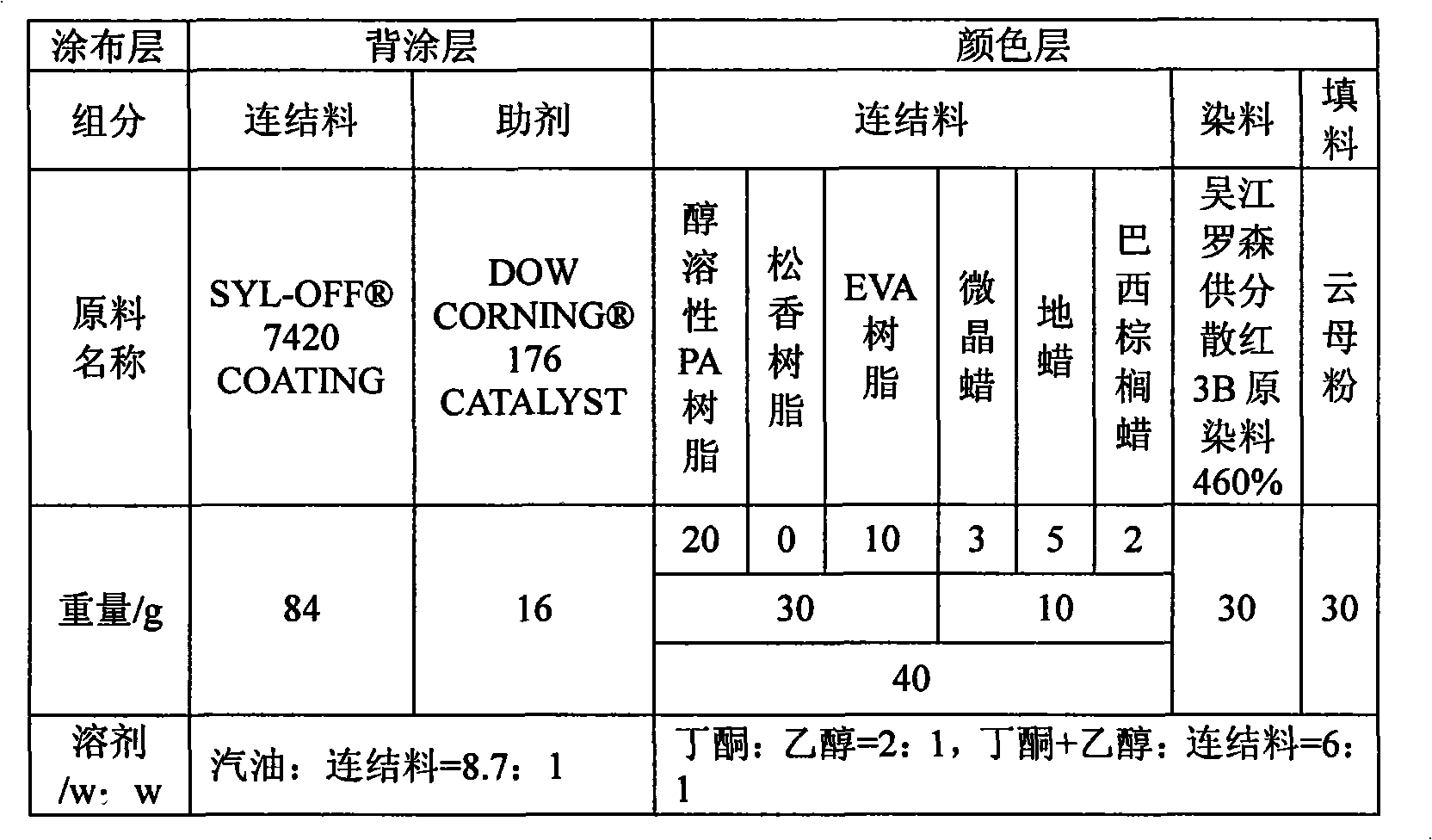

Embodiment 3

[0054]

[0055] Preparation process: After diluting and mixing the binder of the back coating with gasoline in step a, add additives in proportion and mix evenly 40 minutes before use, the drying temperature is 32°C, the thickness of the tape base is 4.3 μm, and the thickness of the back coating is 0.1 μm ; In step b, the melting temperature is 50°C, the drying temperature is 60°C, and the thickness of the color layer is 7 μm; the others are the same as in Example 1, and the total thickness of the obtained thermal sublimation banner printing ribbon suitable for low-speed transfer printing is 11.4 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com