Method and device for water production by electrolysis with compensation for water velocity

A water flow rate, electrolyzer technology, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of large changes in the pH value of electrolyzed water, and achieve the effect of maintaining a constant application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

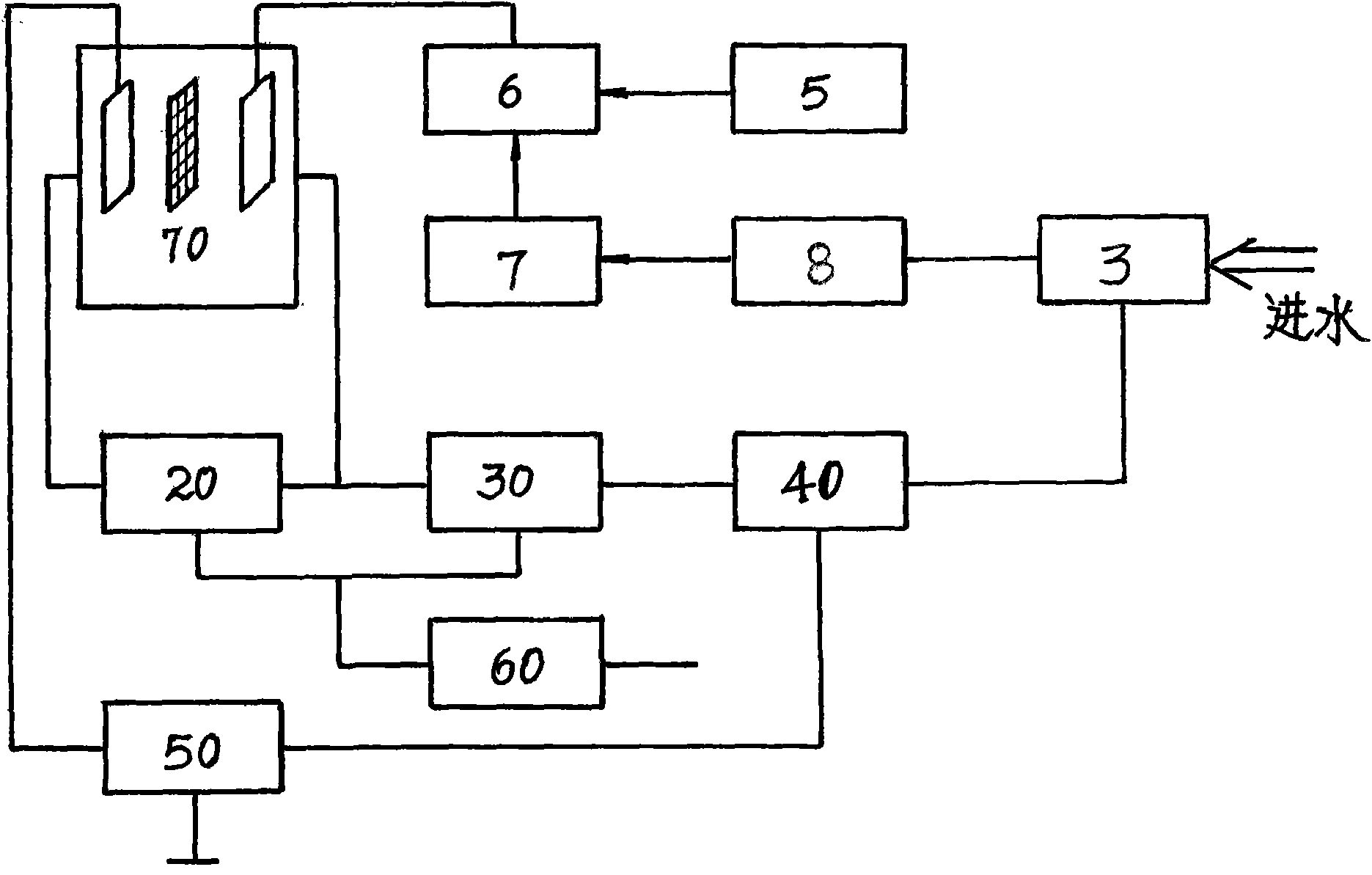

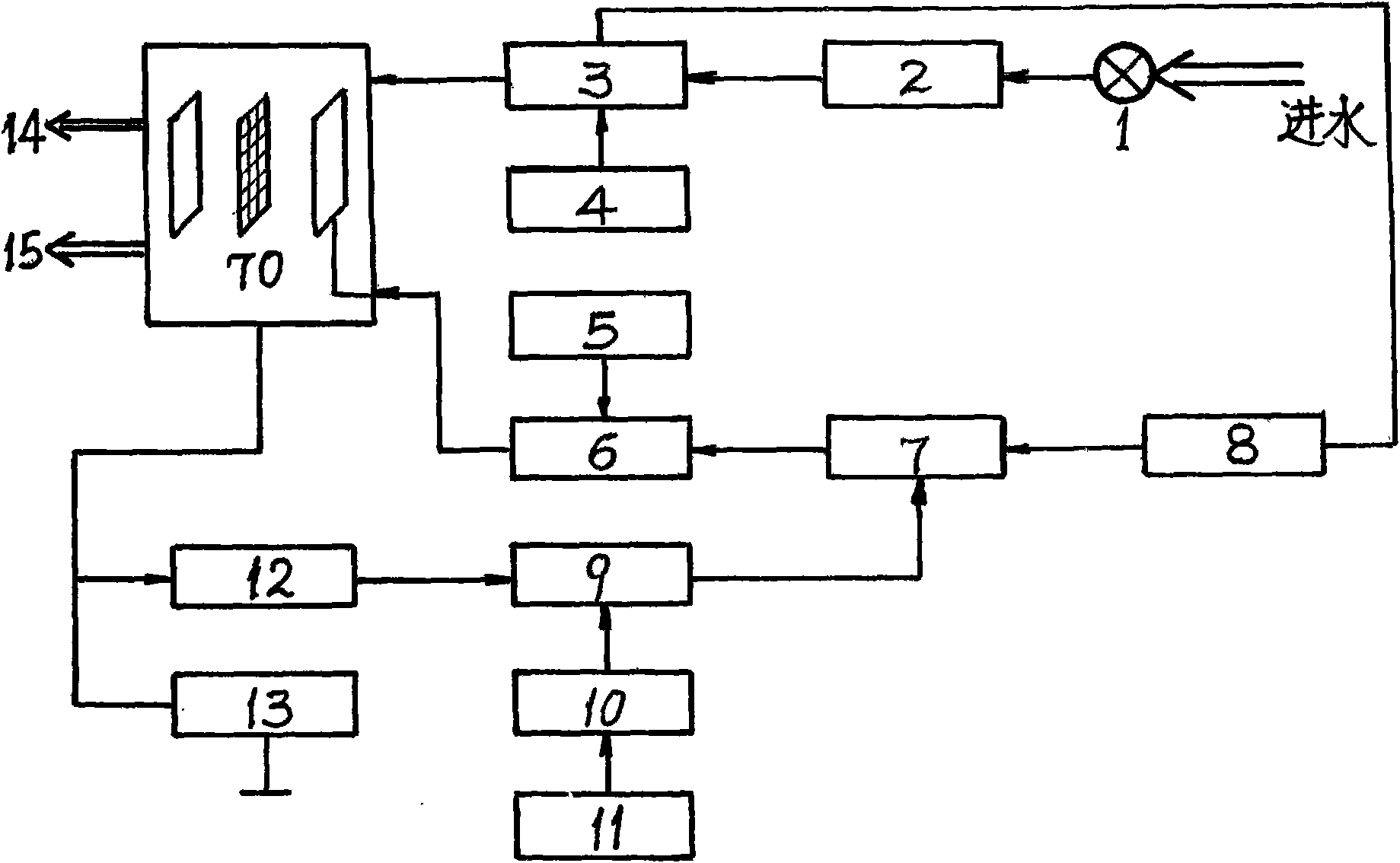

[0033] The invention includes an electrolytic current error sampling circuit unit, an automatic water quality identification unit, a comparison operation circuit unit, a pulse width modulation circuit unit, a push circuit unit, a reference voltage signal switch unit, and an electrolytic cell. Connect an external 220V AC power supply 5 to a DC power supply 6 with a rectifier. One end of the DC power supply 6 is connected to one pole of the electrolytic cell 70 with a wire, and the other end of the DC power supply 6 is connected to the power adjustment switch 7 of the electrolytic power supply; the water source enters the water from the water inlet. Flow velocity detection circuit unit 3, one end of the water flow velocity detection circuit unit (3) is connected to the reverse pole circuit unit 8, and the other end of the reverse pole circuit unit 8 is connected to the pulse width adjustment circuit unit 40; one end of the pulse width adjustment circuit unit 40 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com