Hot rolled bainite steel rail and production process

A production process, bainite technology, applied in the field of rails containing bainite structure and production technology, can solve the problems of unstable rail performance, decreased rail safety, low elongation, etc., to reduce alloy costs and improve strength , the effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

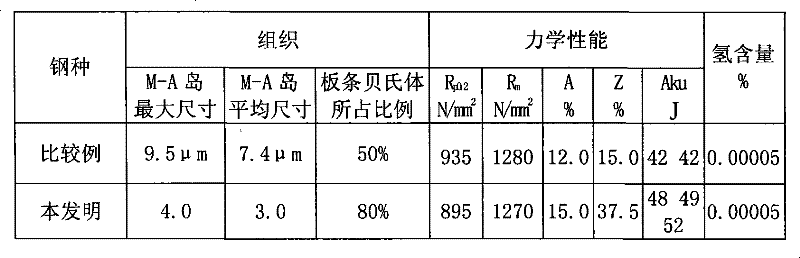

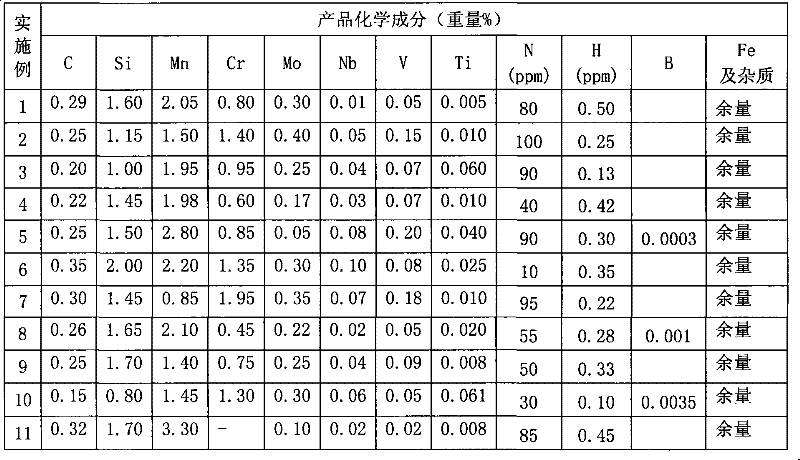

[0015] The chemical composition of the present invention includes, by weight percentage, C: 0.10%-0.35%, Si: 0.80%-2.00%, Mn: 0.80%-3.30%, Cr: <2.00%, N: 0.0010%-0.0100%; in addition Add Nb: 0.01%-0.10%, V: 0.02%-0.20%, Ti: 0.005%-0.060%, Mo: 0.10%-0.40%; control the H content to be less than 0.00005%, and the rest is iron and unavoidable impurities.

[0016] In order to further refine the crystal grains, B: 0.0005%-0.0035% can also be added.

[0017] For the steel with the above chemical composition, when rolling the steel rail, the technical characteristics are that the continuous casting billet is heated to 1200-1360 ℃ and rolled into the steel rail. With the increase of the rolling pass, the rolling temperature gradually decreases. The pass method, the rough rolling rolling temperature is 1230-1020 ℃; the universal method is used in the finishing rolling, the rolling temperature is 1120-850 ℃, and the rolling interval between two adjacent passes is controlled at more than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com