Compression resistance tester of combined paper box

A tester and combined technology, which is applied in the field of combined carton compression tester, can solve problems such as single function and complex structure, and achieve the effect of uniform pressure, low cost and stable pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

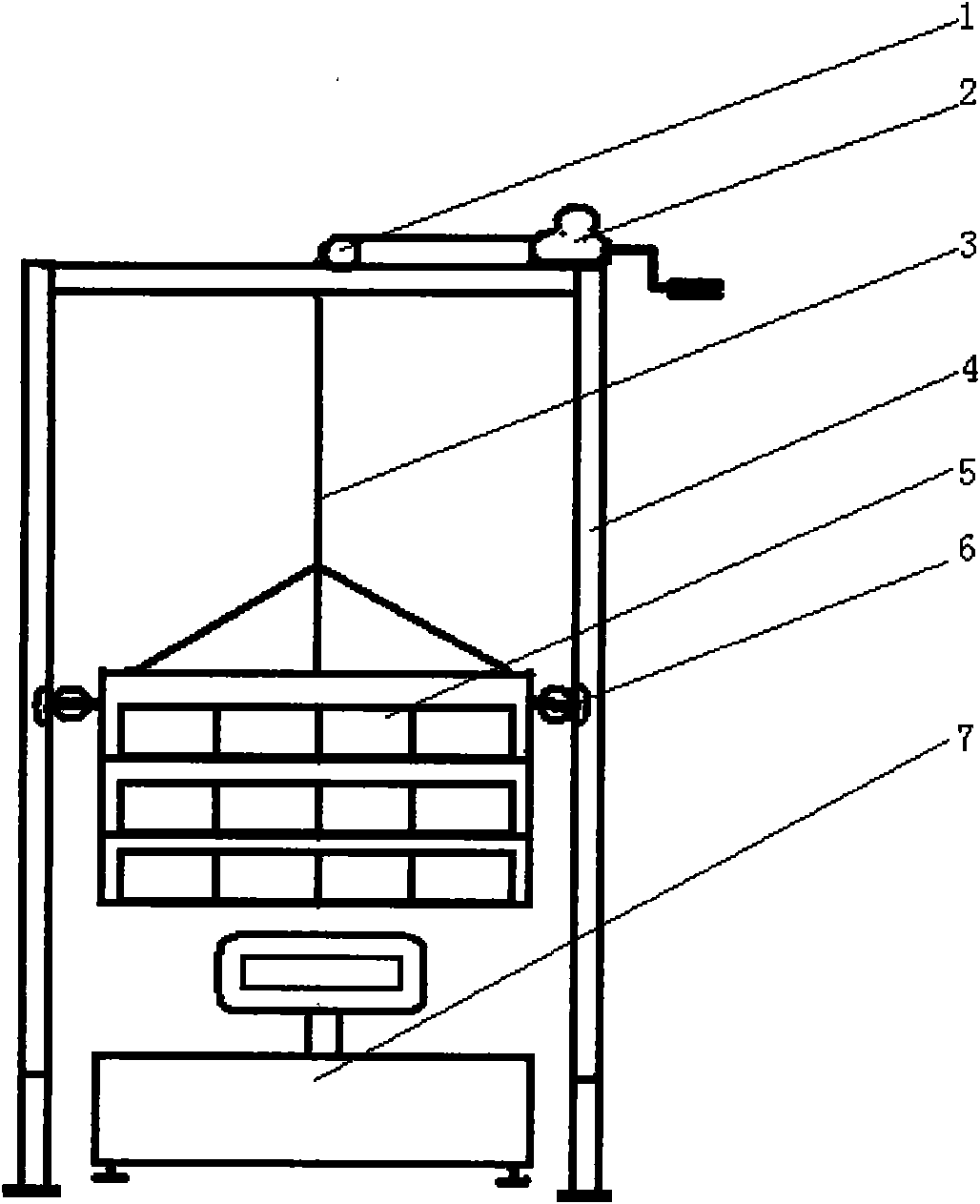

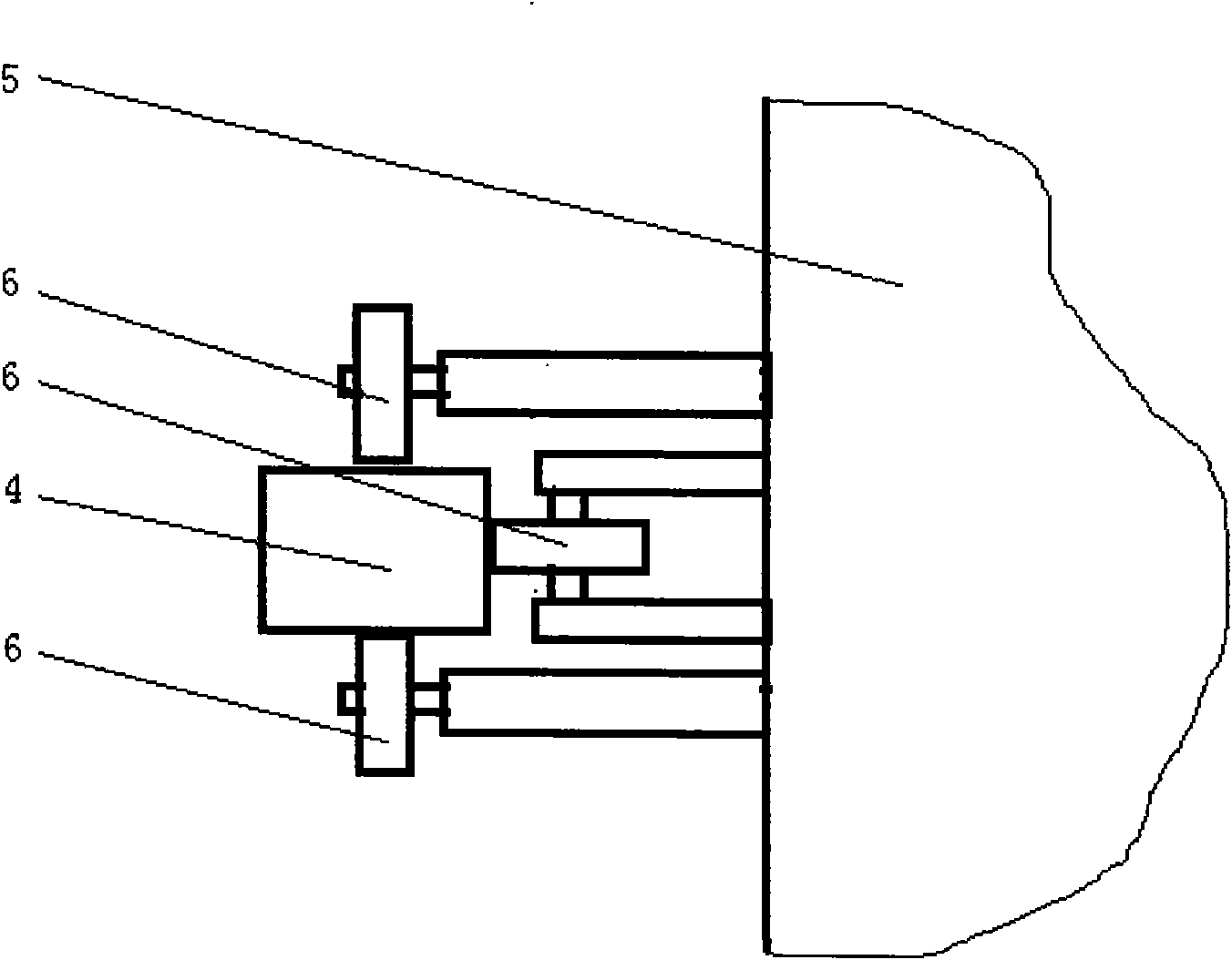

[0008] The weight box 5 is suspended under the gantry frame 4, and there is a turbine reducer 2 on the gantry frame 4. One end of the wire rope 3 is wound on the output shaft of the turbine reducer 2, and the other end of the wire rope 3 is connected to the weight box 5 through the fixed pulley 1. At the top, control the weight box 5 to descend slowly by hand cranking the turbo reducer 2 to control the downward pressure to increase slowly. Since the compression resistance of the carton is generally within 200 kg, the weight of the weight box 5 is set to 220 kg. An electronic platform scale 7 is placed under the weight box 5 as a pressure sensing display. There are three directional pulleys 6 on both sides of the weight box 5 corresponding to the positions of the uprights of the gantry 4 , which roll along the uprights of the gantry 4 and play a role of directional stabilization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com