Infrared detection method of faulty soldered joint of printing circuit board

A printed circuit board and infrared detection technology, which is applied in the field of infrared thermal imaging non-destructive detection of printed circuit board virtual solder joints, can solve the problem that the influence of solder joint appearance, volume and shape uncertainty cannot be ruled out, and it is not easy to load incident Accurate control of the angle, no obvious change in the surface temperature of the solder joints, etc., to achieve the effects of improved accuracy, easy operation, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

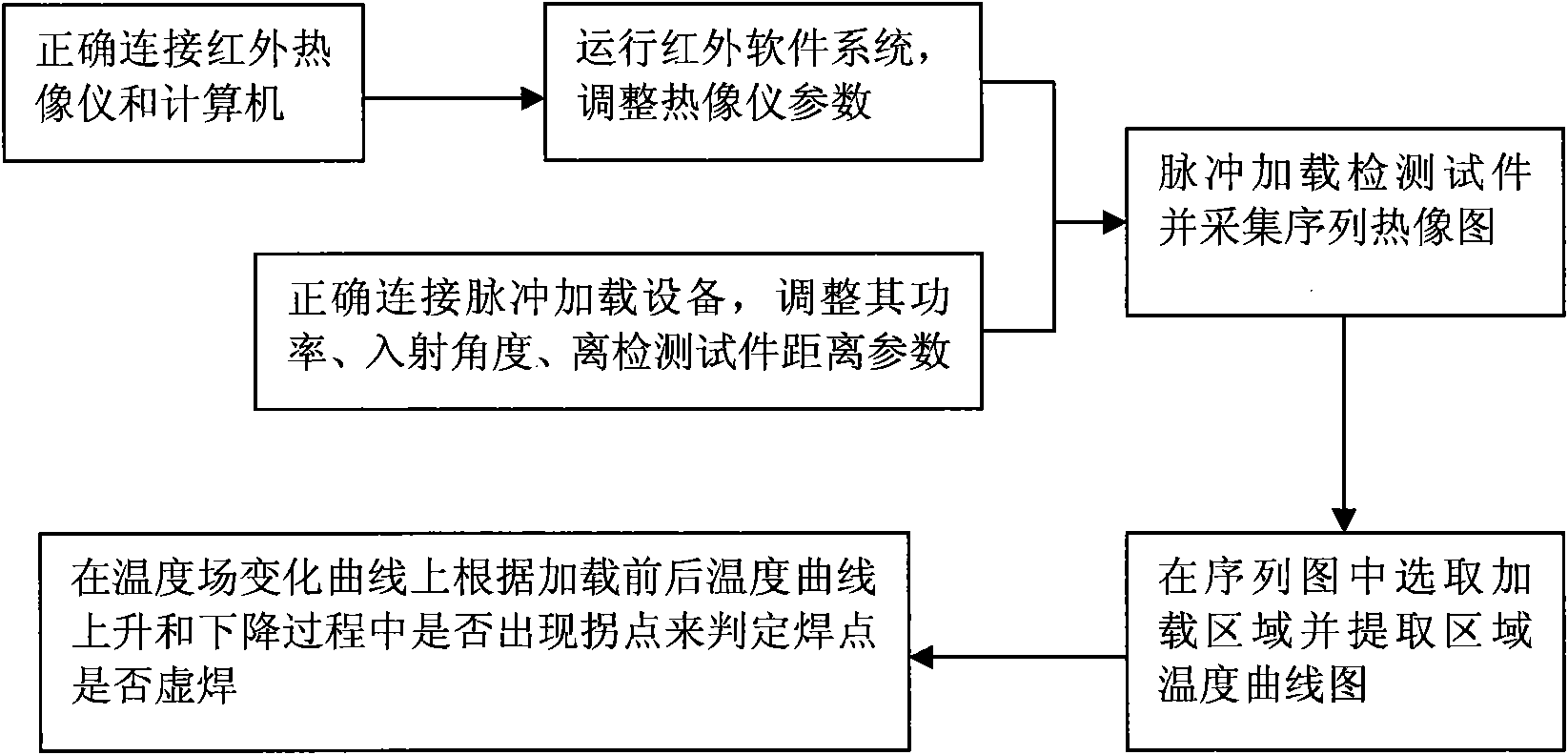

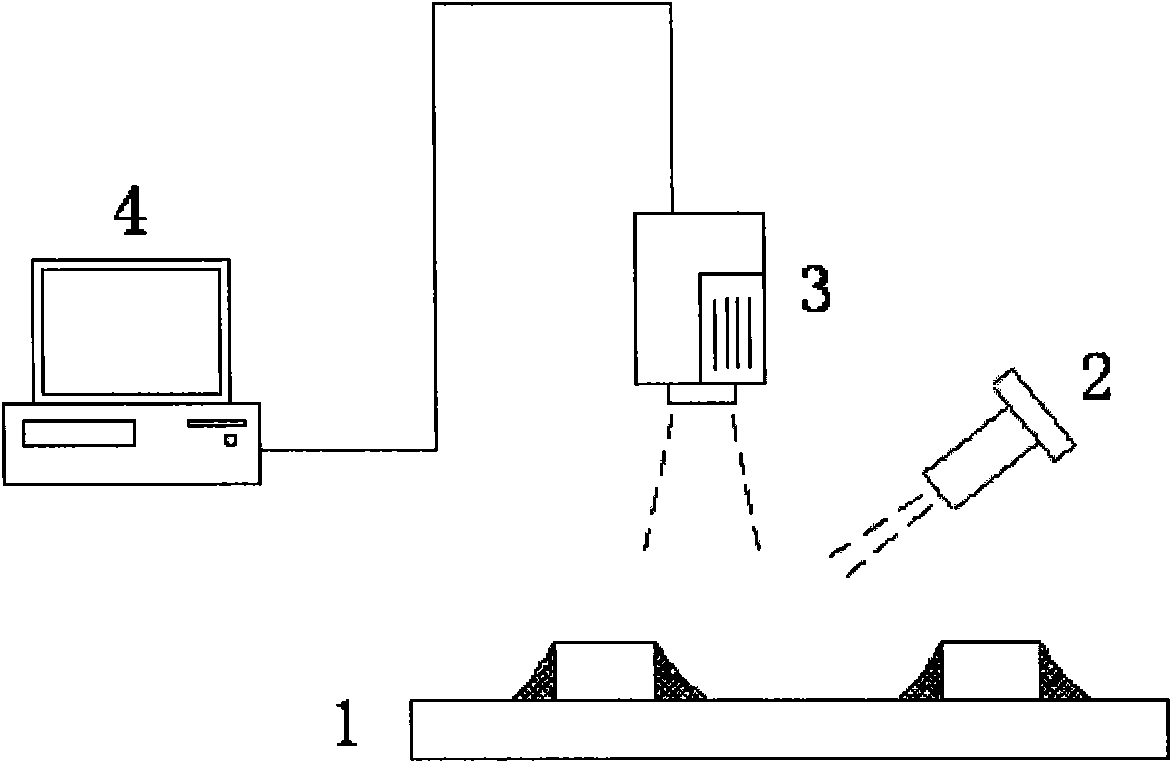

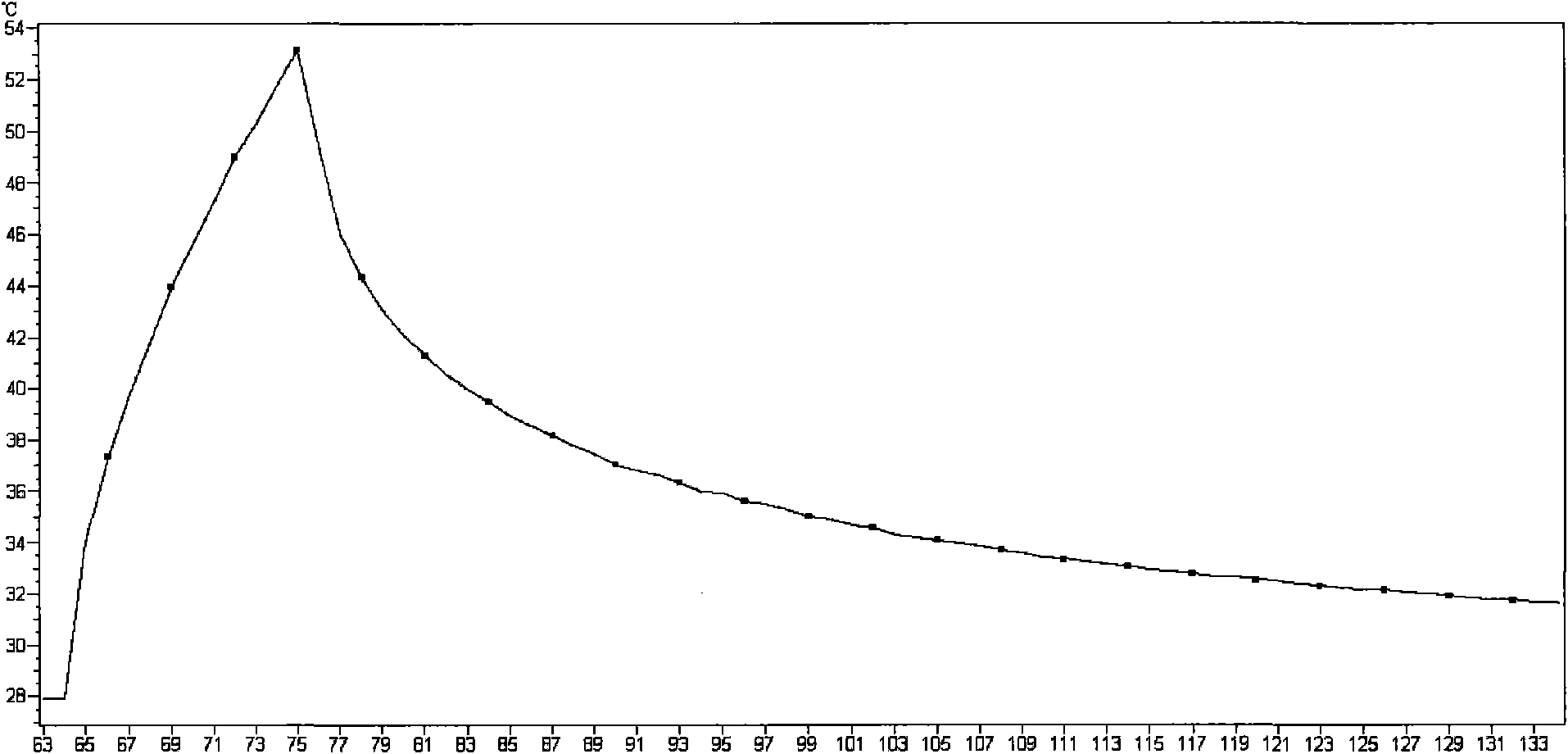

[0025] like figure 1 As shown, it is a scheme flow diagram of the detection method of the present invention, which mainly includes six steps. First, connect the thermal imaging camera and computer equipment correctly, see figure 2 ;Secondly, turn on the thermal imager and adjust its parameters, such as focal length, emissivity, sampling frequency, distance from the test piece, etc., wherein the acquisition frequency of the thermal imager is determined according to the rate of change of temperature; again, the pulse loading must be connected correctly equipment, adjust its power, incident angle, and distance parameters from the test piece, see figure 2 ; Next, pulse loading is performed on the test piece, and at the same time, the sequence thermal image is collected by the computer and stored on the hardware device; then, it is necessary to select the loaded area in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com