Membrane stack structure

A membrane stack and periodic structure technology, applied in optical components, optics, instruments, etc., can solve the problems of poor spectral filtering effect, decreased reflectivity of transmission spectrum characteristics, reflection band, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

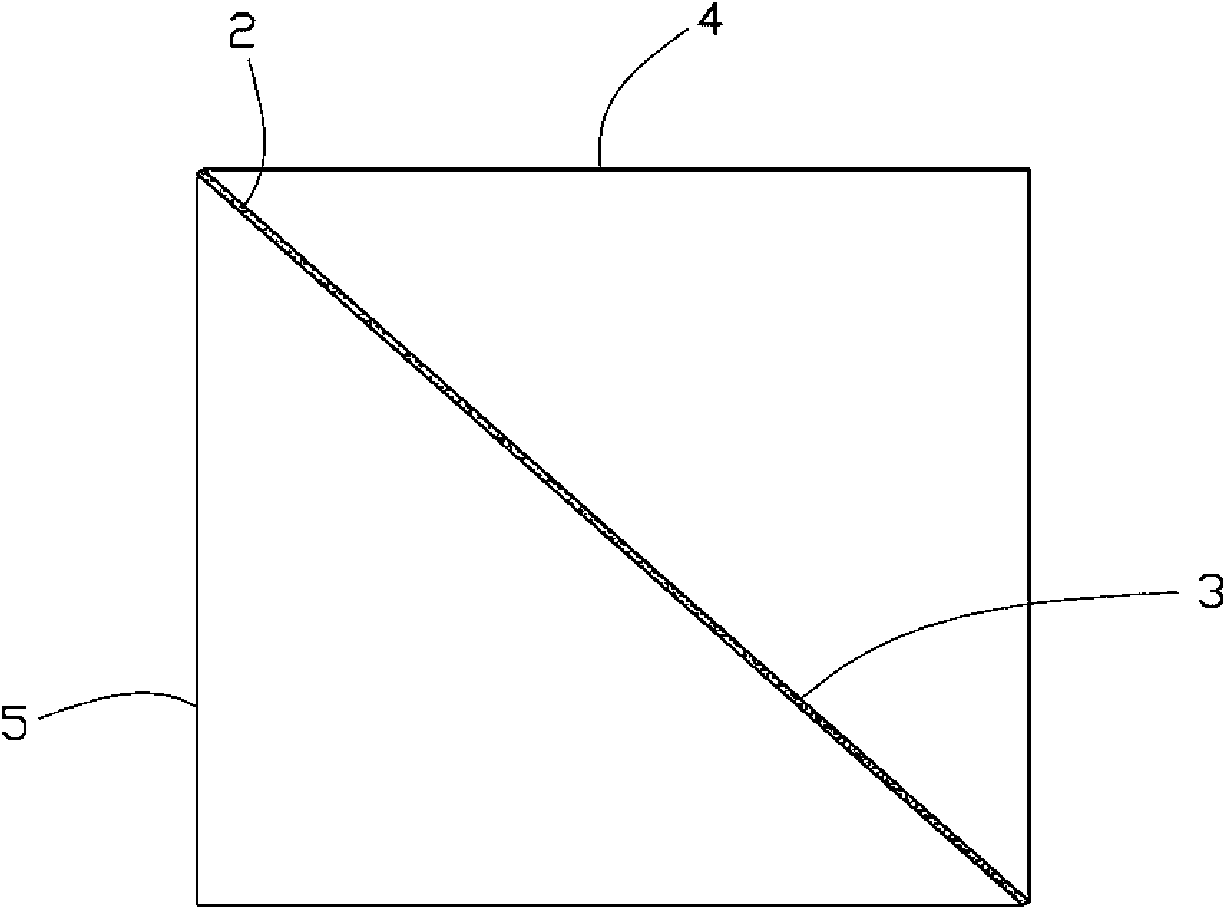

[0020] see Figure 5 , which is a schematic diagram of the membrane stack structure 10 provided by the present invention. The membrane stack structure 10 includes a transparent substrate 102 and a periodic membrane stack 104 stacked thereon. The periodic structure of the periodic film stack 104 is a high refractive index film layer 106 and a middle refractive index layer 108 stacked alternately. The periodic structure of the periodic membrane stack 104 can be expressed as (HM) n , wherein, H represents a high refractive index film layer 106, M represents a middle refractive index film layer 104, the ratio of the coefficients in front of H and M represents the optical thickness ratio of each refractive index film layer, and the superscript n represents the periodicity The period number of the structure.

[0021] The periodic membrane stack 104(HM) n The high refractive index film layer 106 and the middle refractive index film layer 108 have the same optical thickness. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com