Method and device for preparing film by scanning and vapor deposition

A device and a technology for scanning brackets, which are applied in the field of scanning vapor deposition film production, can solve the problems of decreased photoelectric conversion rate of glass substrates, uneven film thickness, poor quality consistency, etc., and achieve a simple and feasible method, improve photoelectric conversion rate, and good quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific implementation plan

[0018] The method of the invention is to set a device for swinging or moving the electron gun in the working state, so that the electron gun can carry out spraying in the moving state. In order to achieve uniform coating.

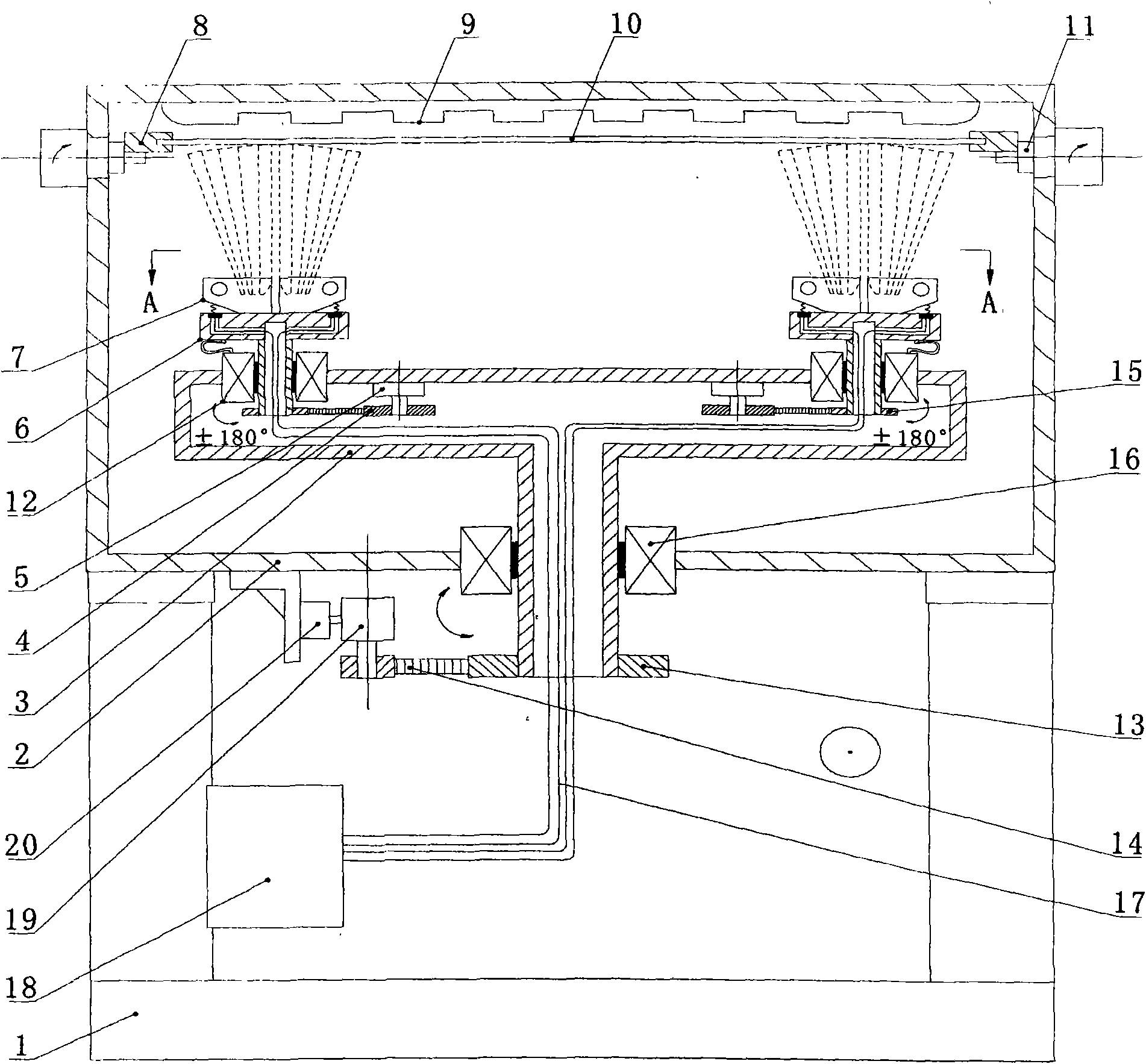

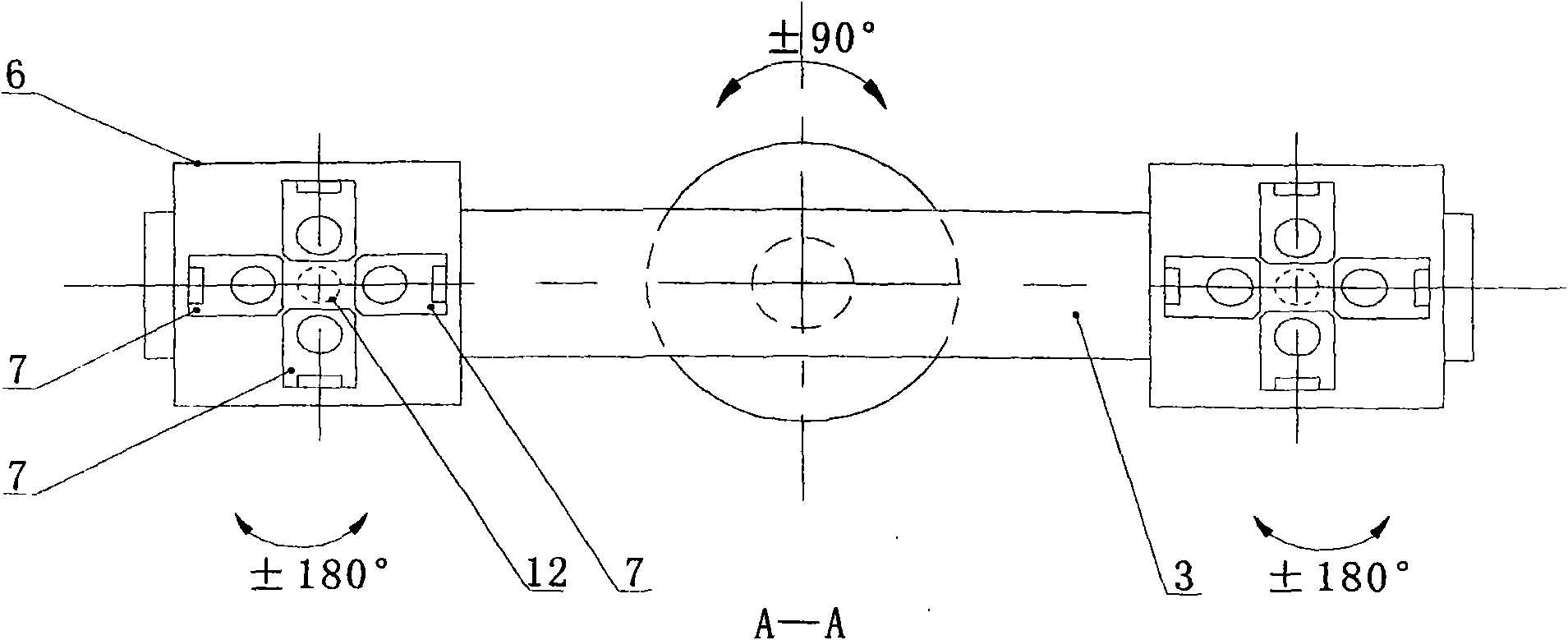

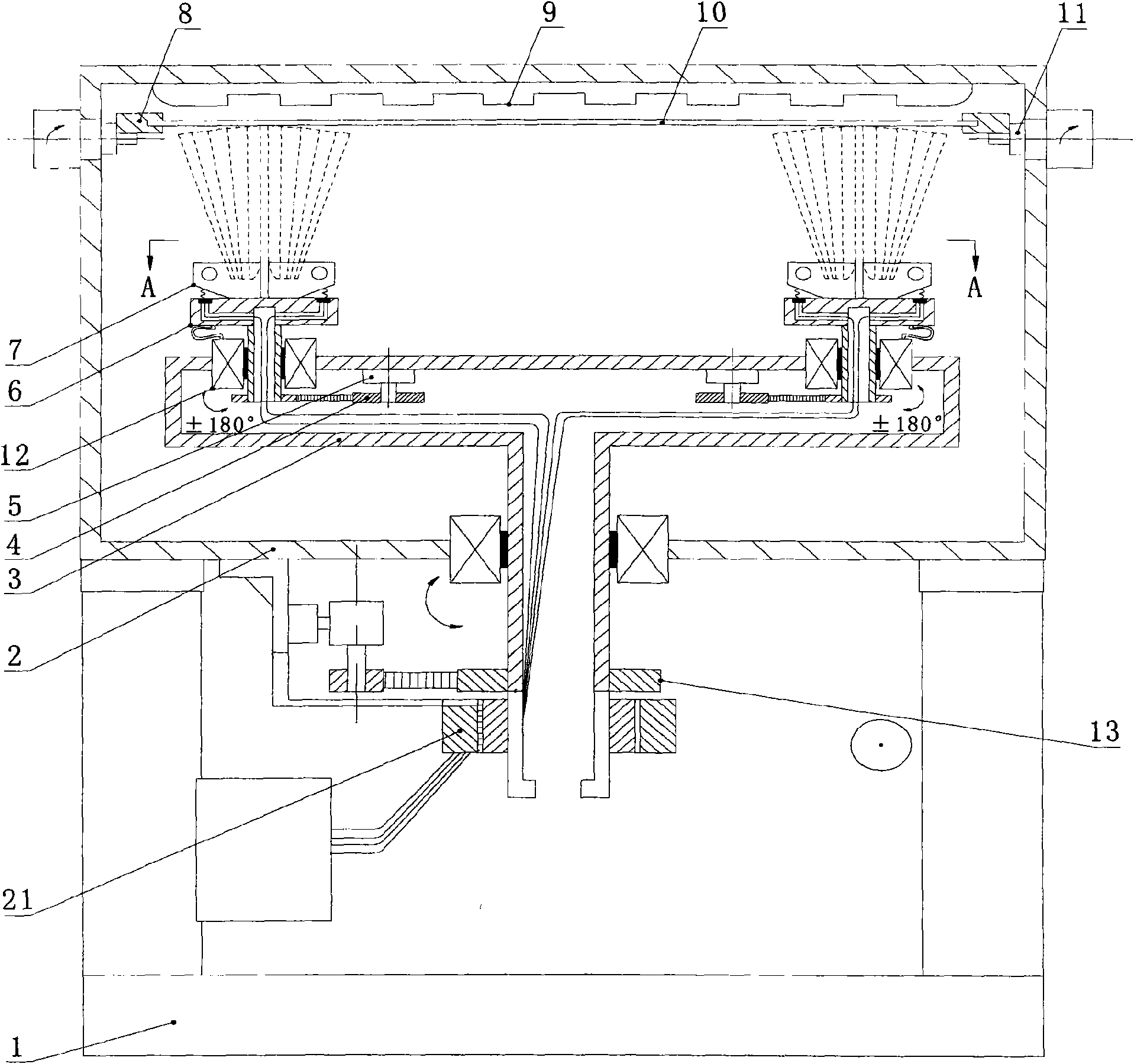

[0019] Such as Figure 1 to Figure 6 As shown, a scanning evaporation film forming equipment is mainly composed of a plurality of electron guns 7 , a frame 1 and a vacuum chamber 2 . The electron gun is located on the swing device, and the electron gun performs spraying in a moving state.

[0020] Such as figure 1 with figure 2 As shown, the oscillating device is composed of a scanning support, a wobble plate and a transmission device. The device rotates and swings both the scanning bracket and the wobble plate.

[0021] The scanning bracket 3 is hollow T-shaped, and the upper end of the T-shaped scanning bracket is located in the vacuum cavity. The scanning bracket and the vacuum cavity are axially connected by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com