Control system and control method for intelligent interlock safe pressure vessel

A pressure vessel and safety pressure technology, applied in the field of intelligent interlock safety pressure vessel control system, can solve problems such as the inability to intuitively realize the setting of pressure and temperature, the inability of the user to realize the man-machine interface dialogue, and the manual control of the opening of the pressure vessel. , to achieve the effect of convenient preparation and modification of process flow, stable work performance, and safety and reliability changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

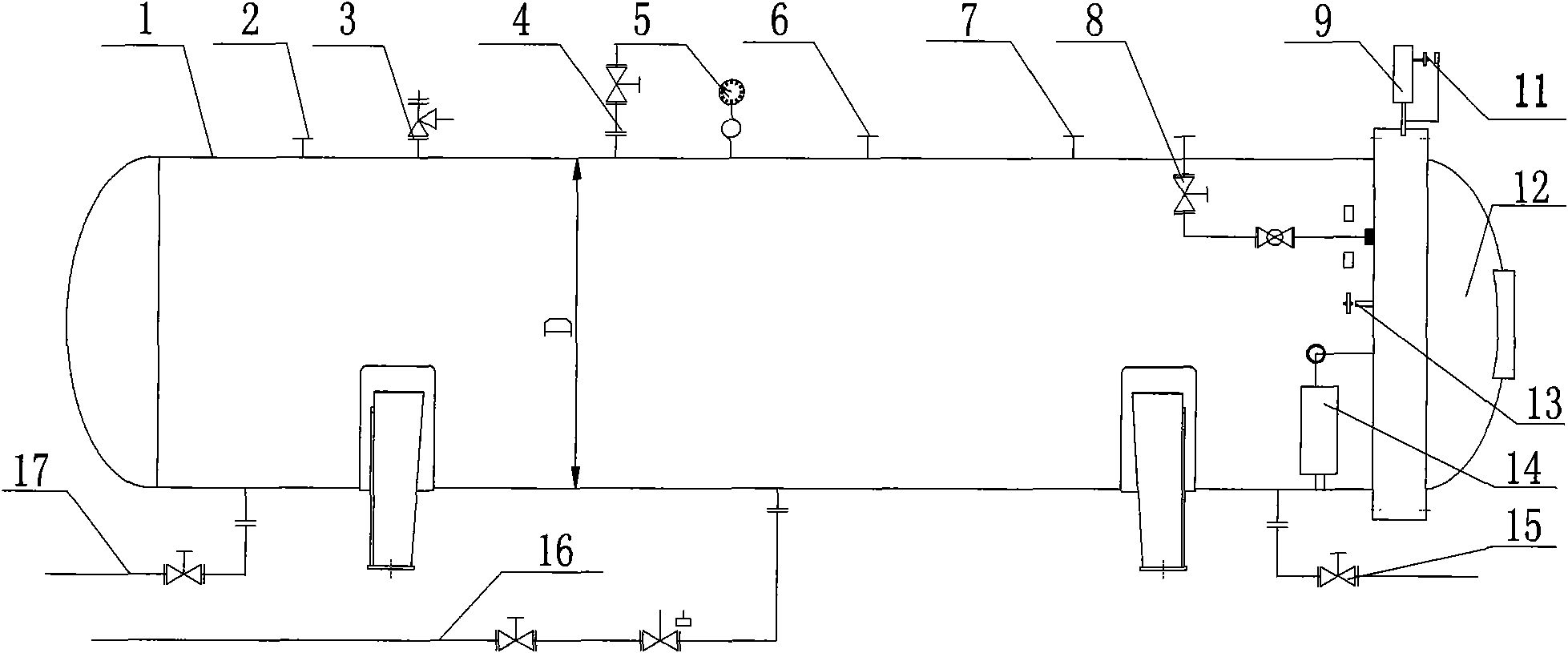

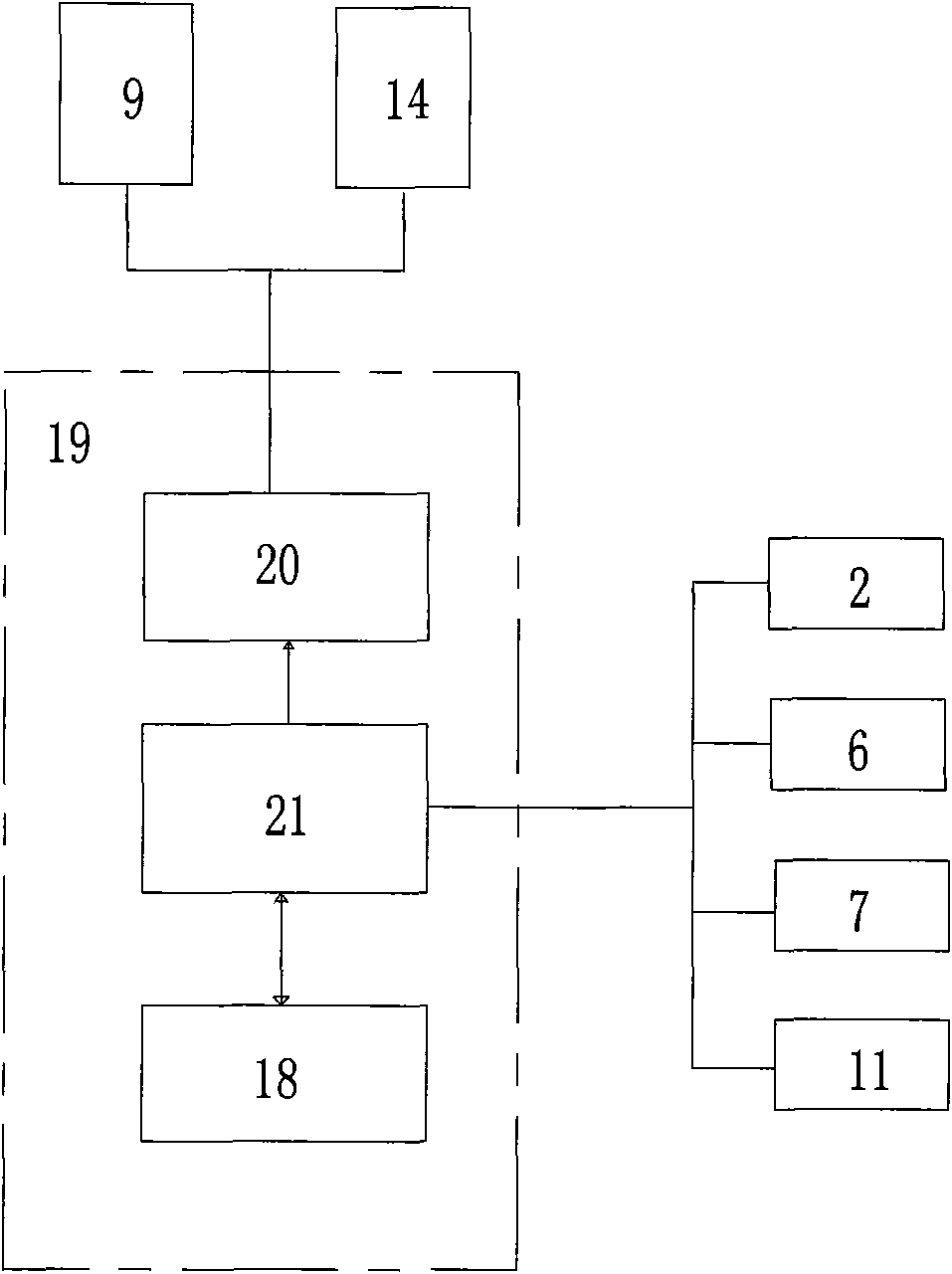

[0010] Example 1: Refer to the attached figure 1 with 2 . An intelligent interlocking safety pressure vessel control system, which includes a pressure vessel 1 and an electric control box 19. The electric control box 19 is composed of a CPU main control board 21, a touch screen 18 and a pneumatic solenoid valve 20. The CPU main control board and the touch screen 18 are bidirectional Data exchange, one-way data exchange with the pneumatic solenoid valve 20. The manufacture of the pressure vessel 1 is based on the prior art, and will not be described here. The upper end of the pressure vessel 1 is provided with a pressure sensor 2, temperature sensors 7 and 8, and the signal output ends of the pressure sensor and the temperature sensor are connected to the signal input end of the electric control box 19; the end cover 12 in the pressure vessel 1 and the pressure The opening and closing of the container body adopts a pneumatic mechanism 14 and a proximity switch 13 matched with t...

Embodiment 2

[0011] Example 2: On the basis of Example 1, the intelligent interlocking safety pressure vessel control method, the CPU main control board has built-in man-machine interface dialogue software and pressure and temperature comparison software, and the user can set it by himself through the man-machine interface touch screen according to the material needs. Set the working pressure, working temperature, and working time of the pressure vessel, and realize segmental control. When work is required, the CPU main control board closes the end cover 12 through the pneumatic electromagnetic command pneumatic mechanism 14. After the end cover 12 is closed in place, The proximity switch 13 with the mechanism transmits the signal that the end cover 12 is closed in place to the CPU main control board. The CPU main control board instructs the latch in the safety interlock actuator 9 to lock the end cover 12 with the pressure vessel body, and the proximity switch 11 locks the latch The signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com