Inclined shaft common rail clamping rail man car

A rail-riding and ordinary technology, which is applied in the field of ordinary rail clamping rail-riding vehicles in inclined shafts, can solve the problems of additional installation of brakes and bending of long-wheelbase frames, and achieves compact structure, low renovation cost, and high safety performance. reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

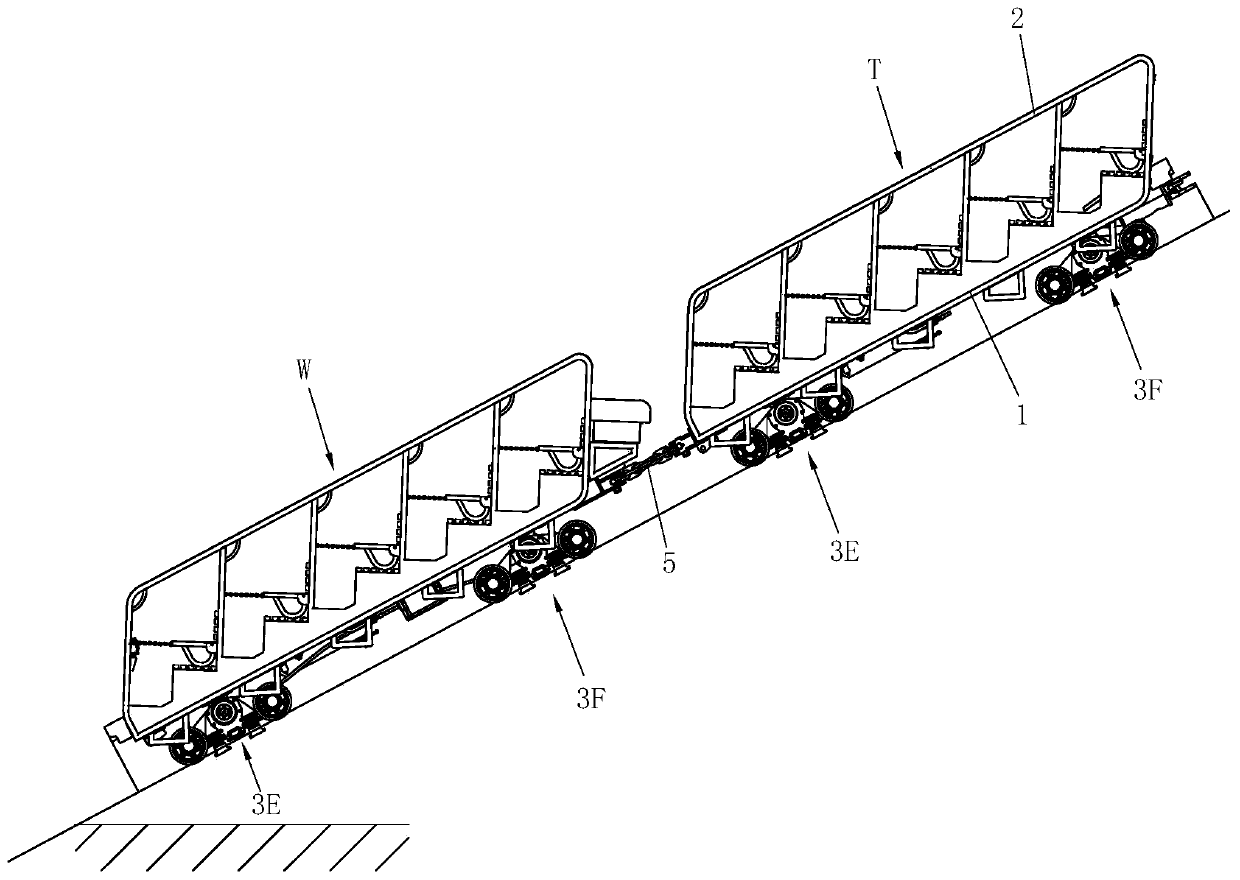

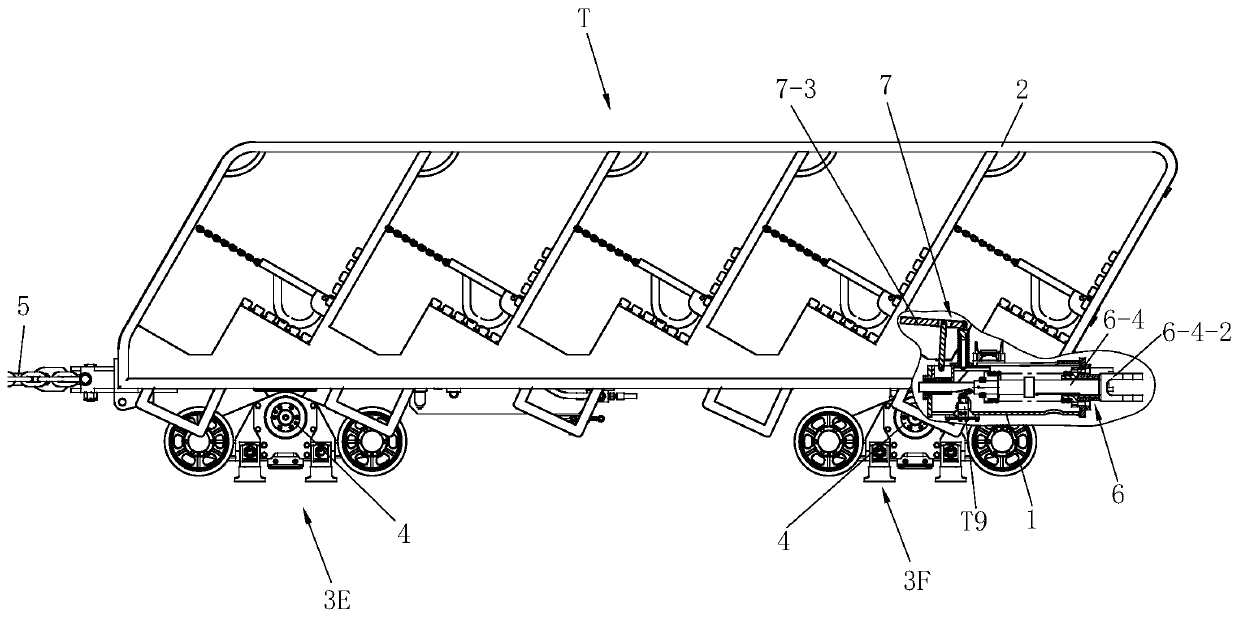

[0043] See figure 1 and figure 2 The passenger car in Embodiment 1 includes a head car T and a tail car W, each of which includes a vehicle frame 1, a compartment 2, a front steering device 3E, a rear steering device 3F and four caliper hydraulic brakes 4, The vehicle frames 1 are connected by connecting rods 5 .

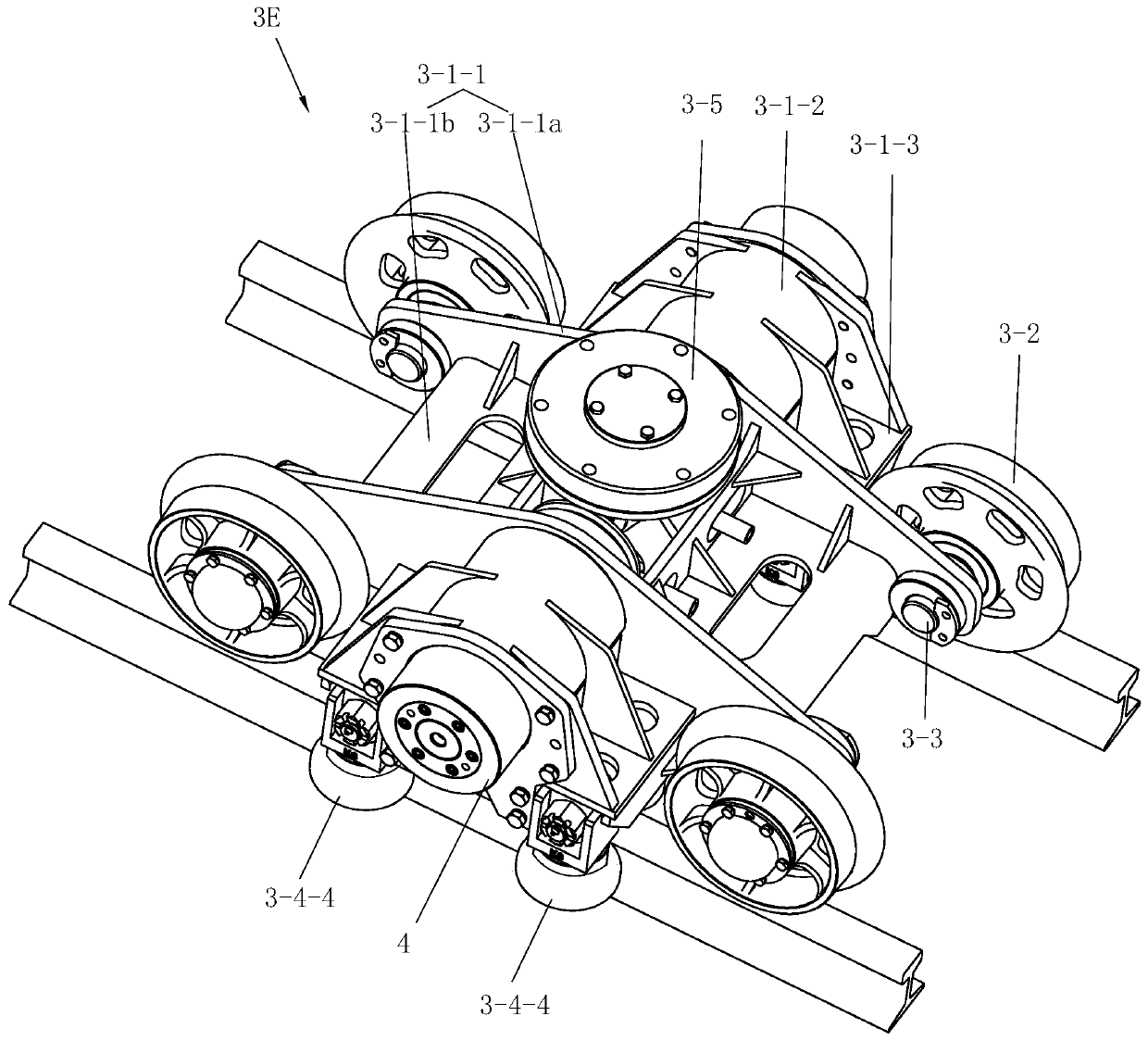

[0044] See Figure 3 to Figure 16 , the front and rear steering devices each have a steering support frame 3-1, and the steering support frame 3-1 has a walking wheel support 3-1-1 of a frame structure, which is respectively arranged on the left and right sides of the walking wheel support 3-1-1 One brake seat 3-1-2 and one rail support 3-1-3 respectively arranged on the front and rear sides of the two brake seats 3-1-2. The walking wheel support 3-1-1 is fixed by two side plates 3-1-1a and two L-shaped support frames 3-1-1b between the two side plates 3-1-1a, wherein the L-shaped support frames The bottom of 3-1-1b is bent downward to increase the strength of ...

Embodiment 2

[0070] Or be provided with at least one mechanical speed taking device 9 on the rear steering device 3F of the head car T, or be provided with at least one mechanical speed taking device 9 on the rear steering device 3F of the tail car W, or be provided with at least one speed taking device 9 between the head car T and the tail car Each rear steering device 3F of W is provided with at least one mechanical speed taking device 9 . In this implementation, the rear steering device 3F of the rear car W is provided with two mechanical speed-taking devices 8 respectively on the left and right sides and opposite, see Figure 20 to Figure 22 , the mechanical speed taking device 9 includes a second large gear 9-1 fixed on the road wheel shaft 3-3, a second mount 9-4 fixed on the corresponding position of the road wheel bracket 3-1-1, and The second speed measuring shaft 9-3 that the second mounting seat 9-4 is dynamically connected, is fixed on the second speed measuring shaft 9-3 one e...

Embodiment 3

[0074] Or on the road wheel bracket 3-1-1 of the rear steering device 3F of the head car, an electric speed taking device 8 and a mechanical speed taking device 9 are respectively located on the left and right sides and opposite, or on the rear steering device of the tail car The traveling wheel support 3-1-1 of 3F is provided with an electric speed-taking device 8 and a mechanical speed-taking device 9 respectively on the left and right sides and facing each other. See Figure 23 , The structures of the electric speed-taking device and the mechanical speed-taking device in Embodiment 3 can refer to Embodiment 1 and Embodiment 2, respectively. See Figure 24 , compared with the hydraulic system of embodiment 1, the hydraulic system of embodiment 3 differs in that the hydraulic system of embodiment 3 has a second cut-off reversing valve W11, and the second cut-off reversing valve W11 is the same as the first cut-off reversing valve T9 is connected in parallel, the first cut-o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com