Chimney internal cylinder glass fiber reinforced plastic expansion joint

A glass fiber reinforced plastic and expansion joint technology, which is applied to expansion compensation devices for pipelines, combustion product treatment, combustion methods, etc., can solve problems such as difficulty in handling expansion joints, leakage, etc. Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

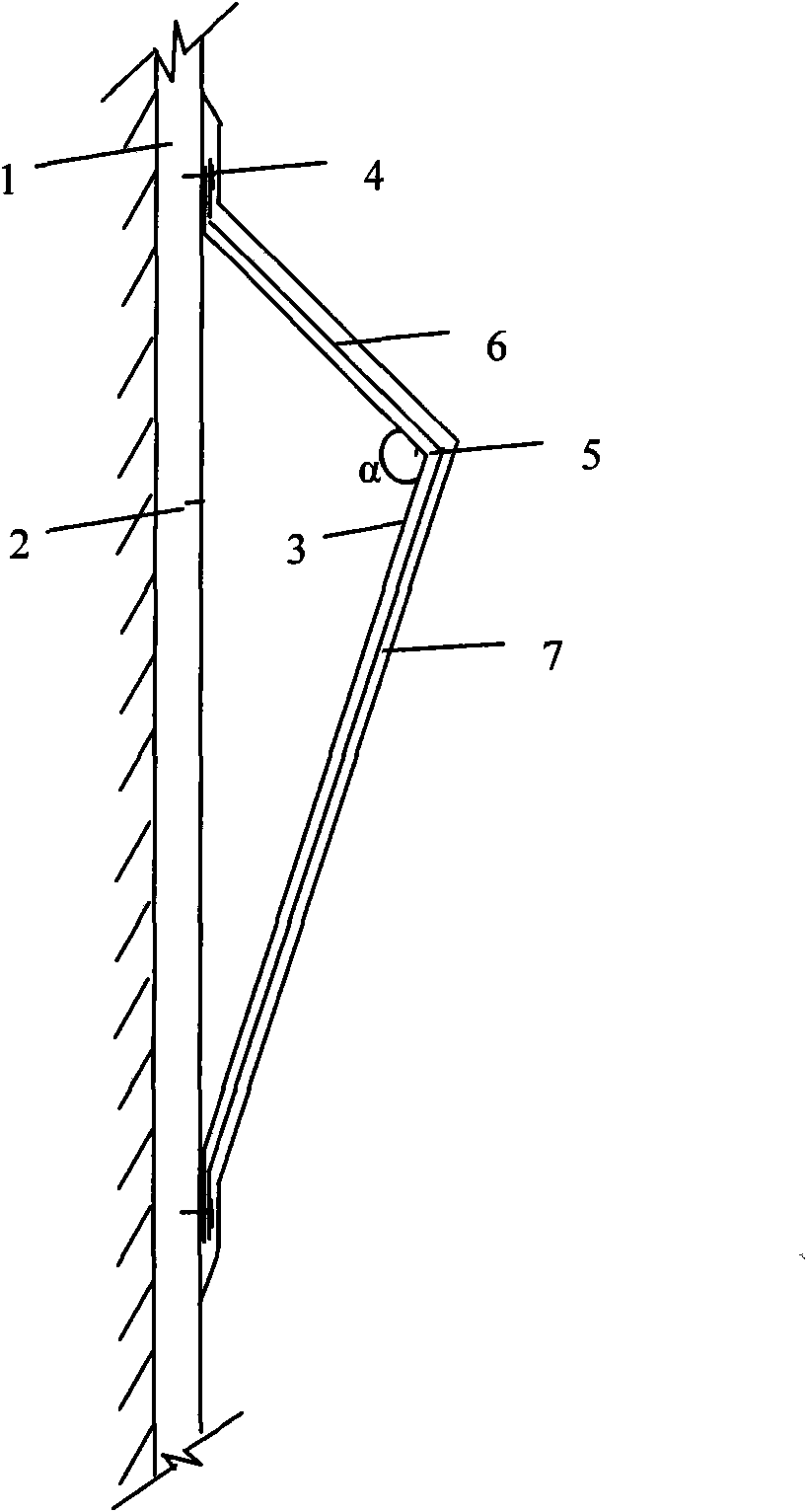

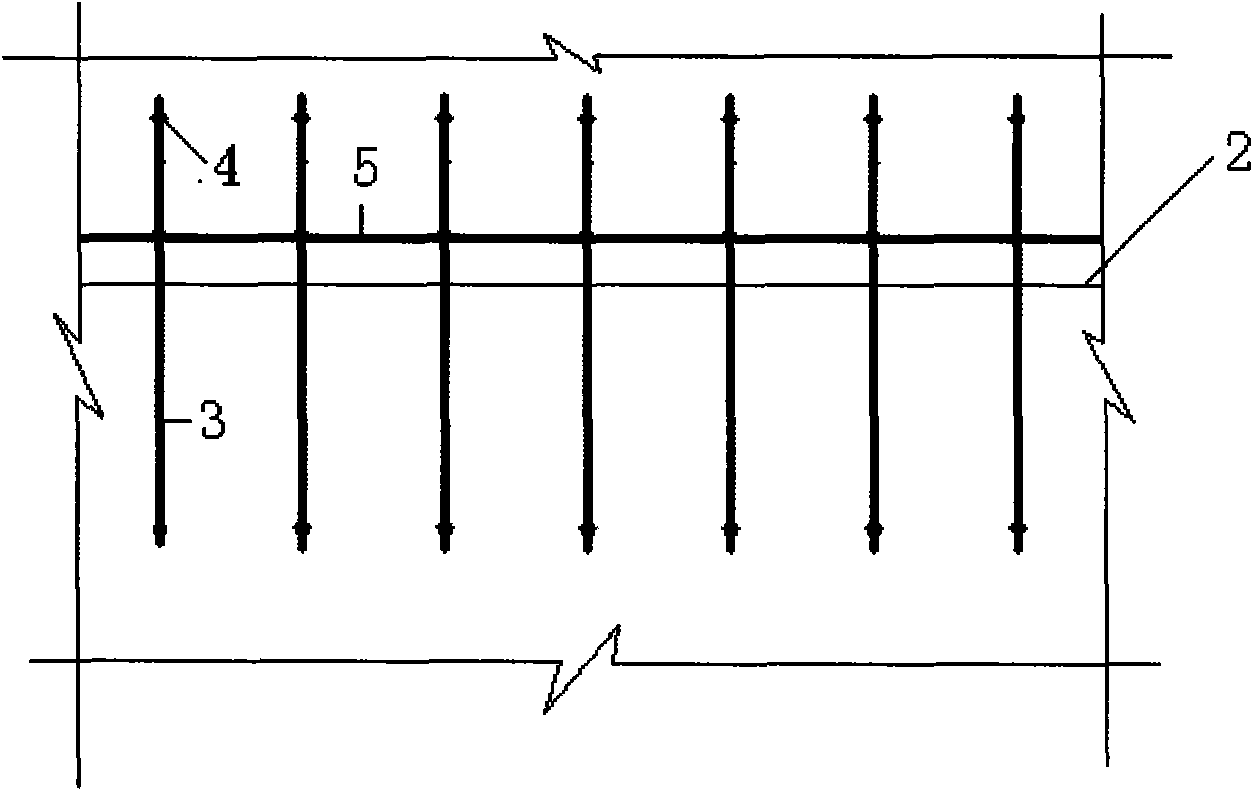

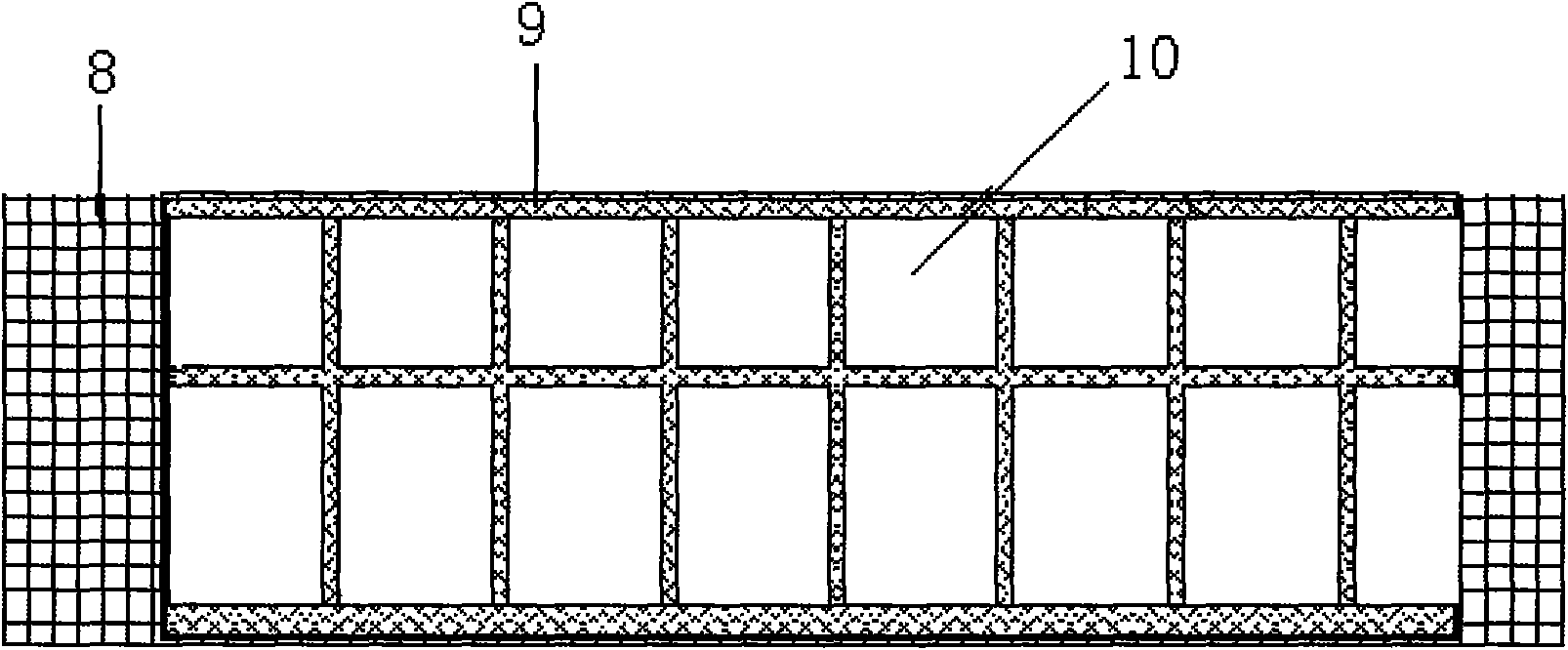

[0021] Such as figure 1 Shown is the cross-sectional view of the FRP expansion joint of the chimney inner tube. The chimney inner tube glass fiber reinforced plastic expansion joint is composed of ">" shaped support spokes 3, nails 4, connecting wires 5, support nets 6 and glass fiber reinforced plastic shells 7. The two ends of the ">"-shaped support spoke 3 are fixed on both sides of the chimney expansion joint 2 on the chimney inner wall 1 by nails 4, such as figure 2 As shown, it is a schematic diagram of the connection of the supporting spokes. The vertices of the ">" shaped supporting spokes 3 are connected together by connecting lines 5, and the outer sides of the ">" shaped supporting spokes 3 and the connecting lines 5 are fixed with supporting nets 6, and the outer sides of the supporting nets 6 are provided with Fiberglass shell 7 is arranged, and the two ends of glass steel shell 7 are fixed on the chimney inner wall 1, as Figure 4 Shown is the front view of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com