LED and production method thereof

A technology of light-emitting diodes and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as contact displacement, displacement, poor bonding yield, etc. It is not easy to shift, and the joint is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings.

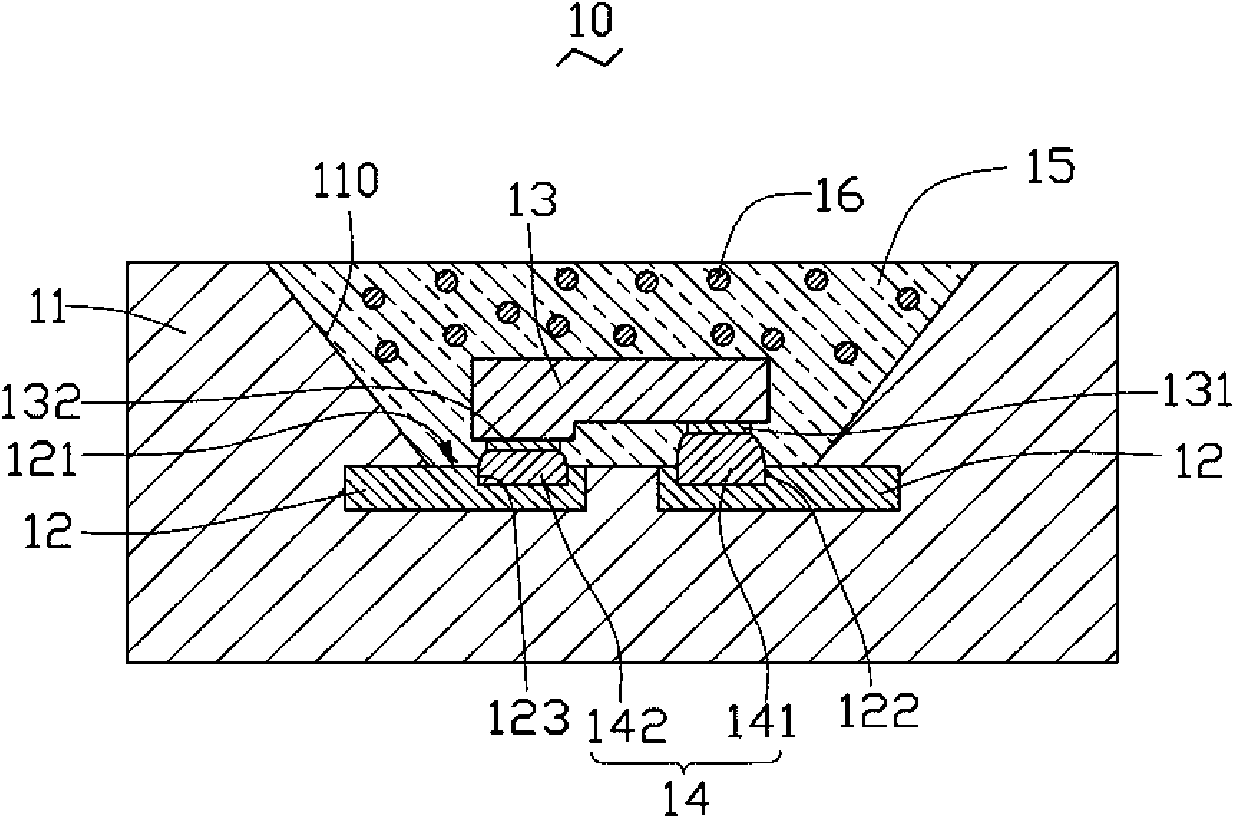

[0015] See figure 2 , the light emitting diode 10 provided by the first embodiment of the present invention includes a housing 11 , a substrate 12 , a light emitting diode chip 13 , a bonding layer 14 , and a packaging layer 15 .

[0016] The packaging case 11 has a receiving groove 110 . The material used for the packaging case 11 is an insulating material, such as liquid crystal polymer (Liquid Crystal Polymer), plastic, and the like.

[0017] The substrate 12 is disposed at the bottom of the containing groove 110 for carrying the LED chip 13 . The substrate 12 is connected to an external power source (not shown in the figure), so that the external power source conducts a driving current to the LED chip 13 through the substrate 12 . The substrate 12 is a lead frame, and its material is a high-conductivity material, such as gold, silver, copper and other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com