Vibration suppressing method and device

A technology of vibration suppression and vibration acceleration, which is applied in the direction of manufacturing tools, metal processing machinery parts, maintenance and safety accessories, etc., to achieve accurate and stable speed, suppress tool wear, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

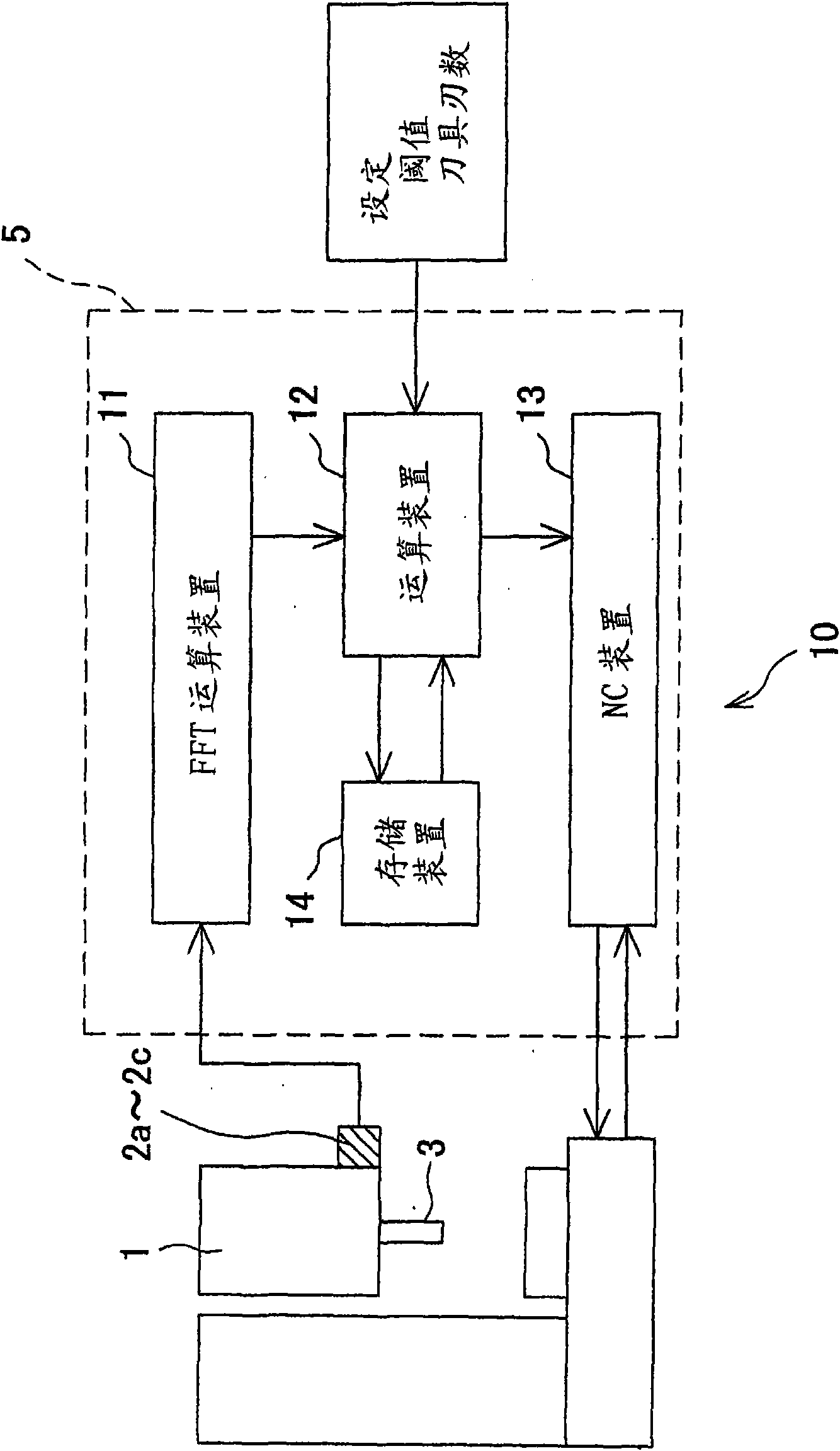

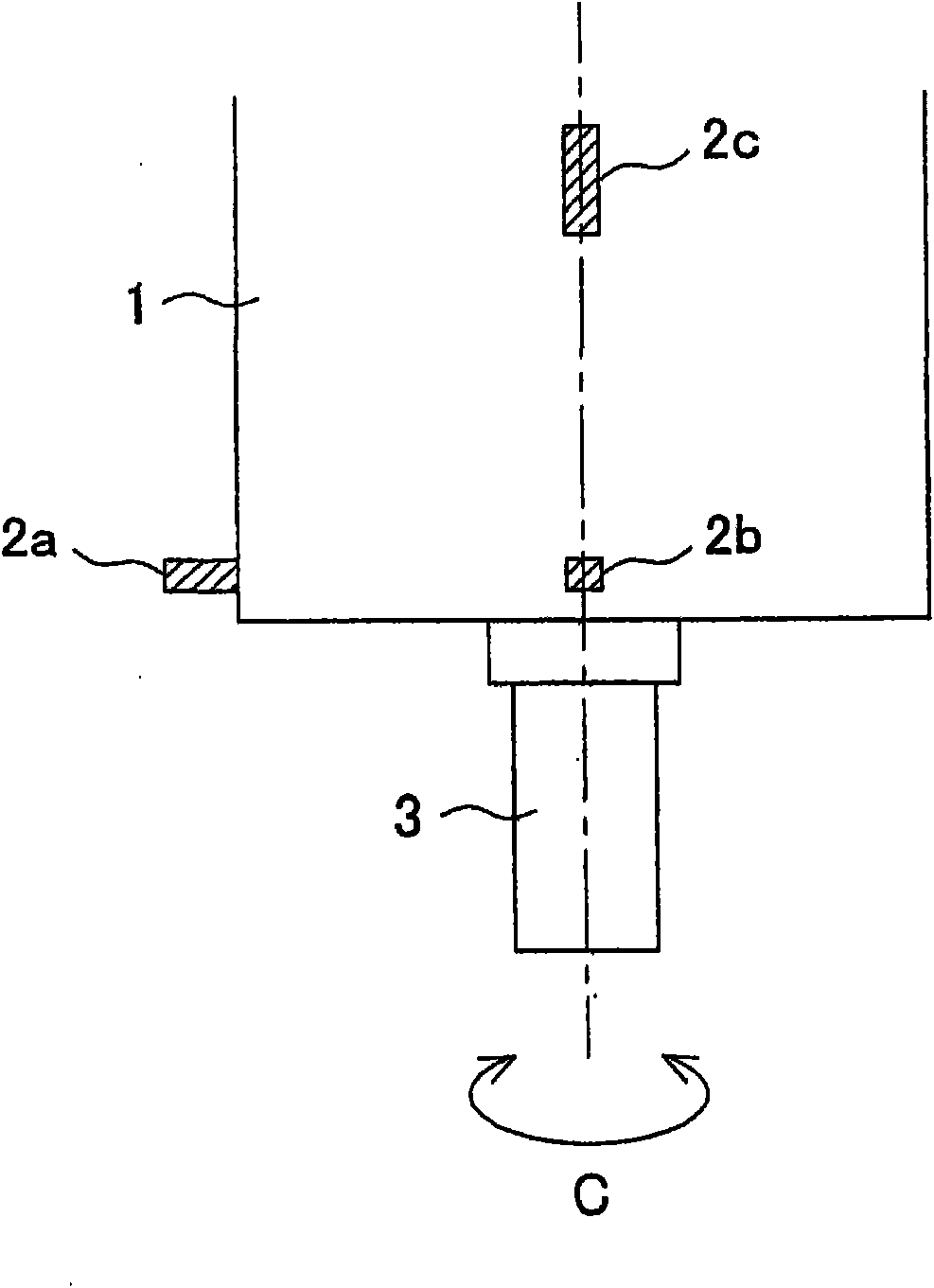

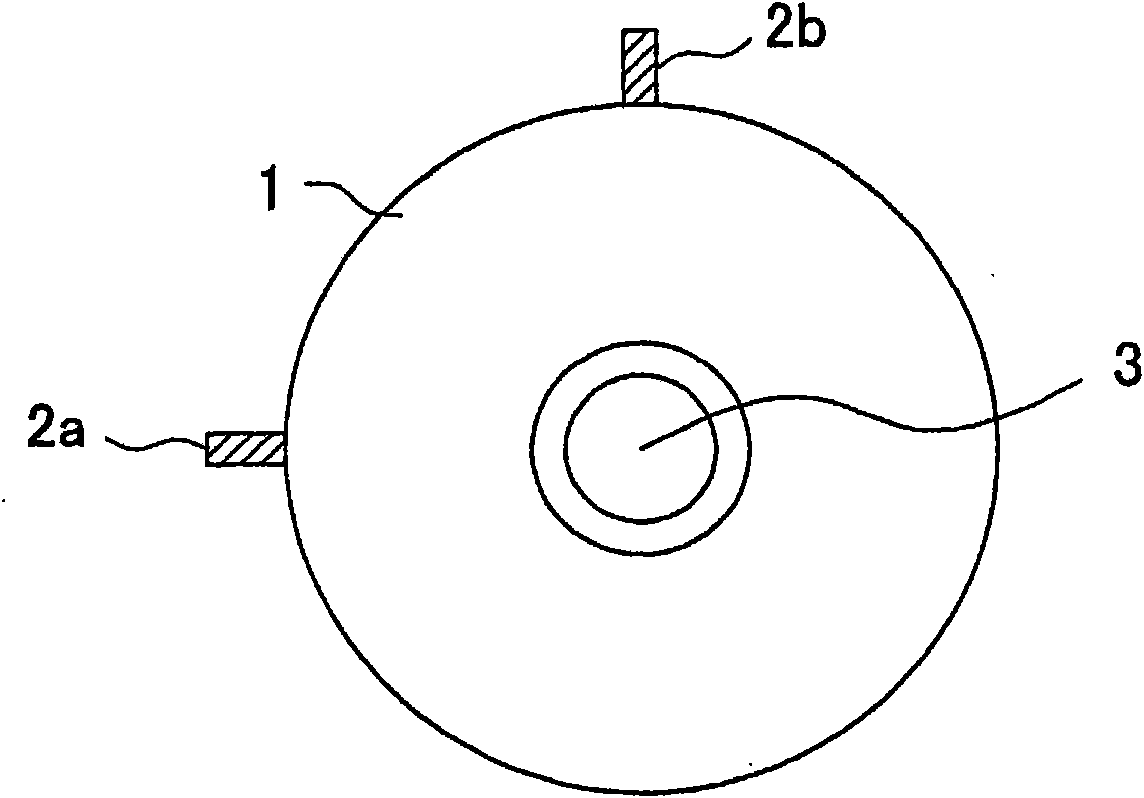

[0046] figure 1 It is a block diagram illustrating the configuration of the vibration suppression device 10 . figure 2 It is an explanatory diagram showing the rotary shaft box 1 as the object of vibration suppression from the side, image 3 It is an explanatory diagram showing the rotary shaft box 1 from the axial direction.

[0047] The vibration suppressing device 10 is used to suppress the "flutter" generated on the rotating shaft 3 arranged to rotate around the C-axis in the rotating shaft box 1. The vibration suppressing device 10 is composed of the following parts: vibration sensors (detection units) 2a- 2c, which is used to detect the vibration acceleration in the time domain (representing the vibration acceleration on the time axis) generated on the rotating rotating shaft 3; and the control device 5, which performs Control the rotational speed of the rotary axis 3.

[0048] like figure 2 and image 3 As shown, the vibration sensors 2a to 2c are installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com