Device and method for making robot track given route at high accuracy

A technology for specifying paths and robots, applied in the field of tracking compensation, can solve the problems that the positioning accuracy of the tool center point cannot meet the requirements of laser welding and the hardware requirements are not high, and achieve the effects of high path tracking accuracy, simple operation and cost reduction.

Inactive Publication Date: 2010-12-01

SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a laser processing head device for tracking a specified path with low hardware requirements, and a path tracking / compensation control method to solve the problem that the positioning accuracy of the tool center point cannot meet the requirements of laser welding when industrial robots perform high-precision path tracking The problem

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

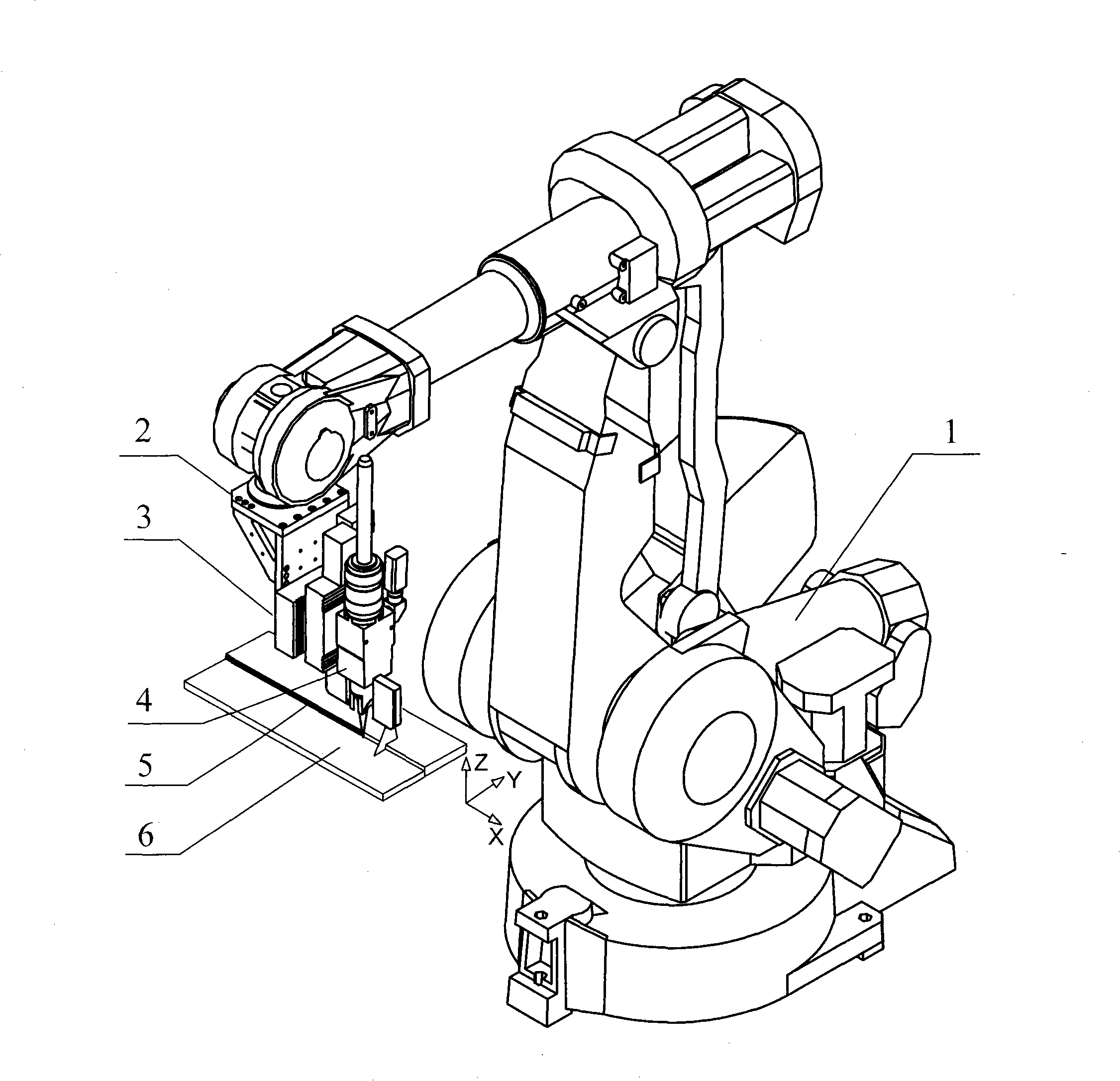

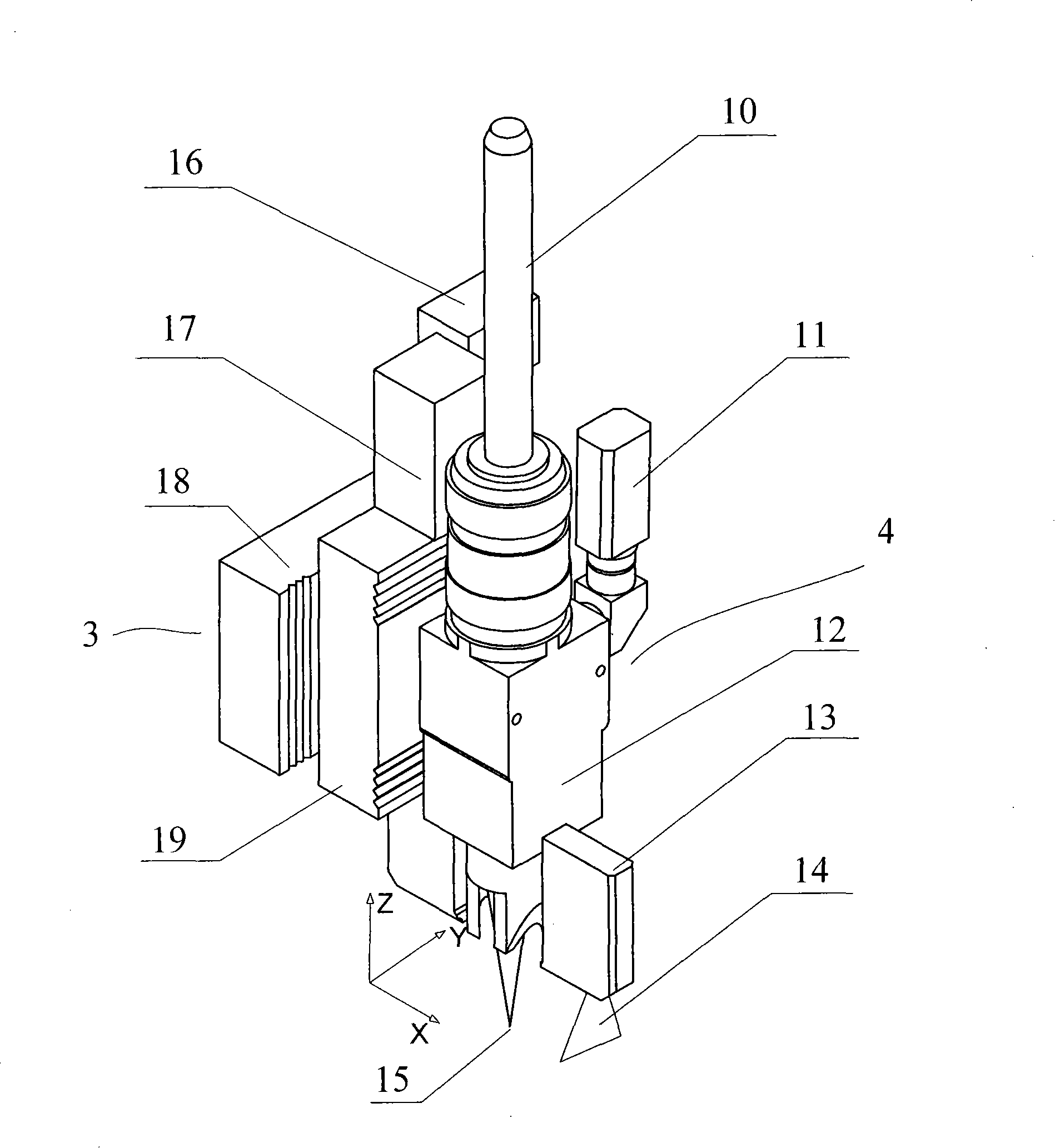

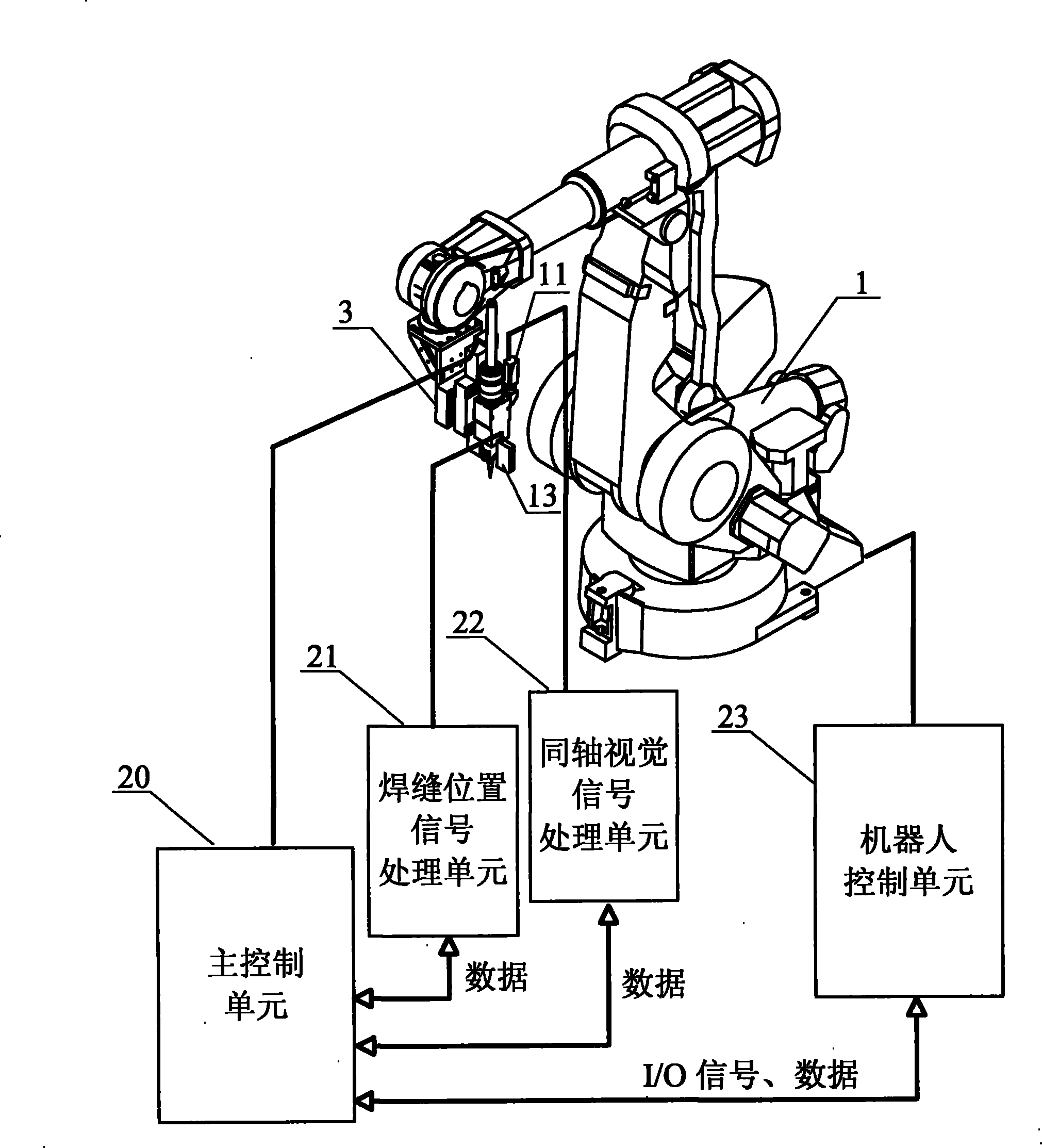

The invention relates to a device and a method for making a robot track a given route at high accuracy, in particular to a robot processing system for performing route tracking and deviation compensation by comprehensively utilizing a coaxial vision sensing system and a welding seam position measurement sensing system, and a route tracking method, which are used for high-accuracy processing of laser welding and the like. The implementation process is divided into three stages; the first two stages comprehensively utilize welding seam position measurement information and coaxial vision measurement information to calculate the deviation between the front welding seam position and the central point of a robot tool and a welding seam so as to obtain the compensation data of the track deviation of the central point of the robot tool and the welding seam position reference data; and the stage of actual welding utilizes the welding seam position measurement information and the welding seam position reference data to perform tracking and compensation control, a position correcting device corrects the motion of a robot system so that the central point of the robot tool moves forwards continuously along the given route, and the deviation of the given route is smaller than the route repeat accuracy of the robot. The device and the method can be widely applied to various occasions required to improve the motion path accuracy of the robot.

Description

A device and method for enabling a robot to track a specified path with high precision technical field The invention relates to tracking compensation technology, in particular to a device and a path tracking compensation method for enabling a robot to track a specified path (such as a welding seam) with high precision. The device and method can enable a robot system with low precision to realize high-precision processes such as laser welding. Background technique Some advanced technology applications hope to use robots with large working space and good motion flexibility, but also put forward high requirements for the positioning accuracy of robots. For example, laser welding has the following remarkable characteristics: the welding speed can reach more than 4m-15m / min, while the welding speed of traditional arc welding is generally only 0.5m-1.0m / min; the tracking positioning accuracy is high, and the welding seam tracking error requirements Within ±(0.05-0.1mm), far bel...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B25J9/10B25J9/22B25J19/02

CPCG05B2219/36405B25J9/1684G05B2219/4705B23K26/0884G05B2219/36407

Inventor 罗振军王琛元贺云姜春英邹媛媛田永利

Owner SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com