A method of estimating the dust load of an esp, and a method and a device of controlling the rapping of an esp

A control device and measurement device technology, applied in the field of rapping devices, can solve the problems of increasing ESP investment and operating costs, and achieve the effect of reducing the increase in emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

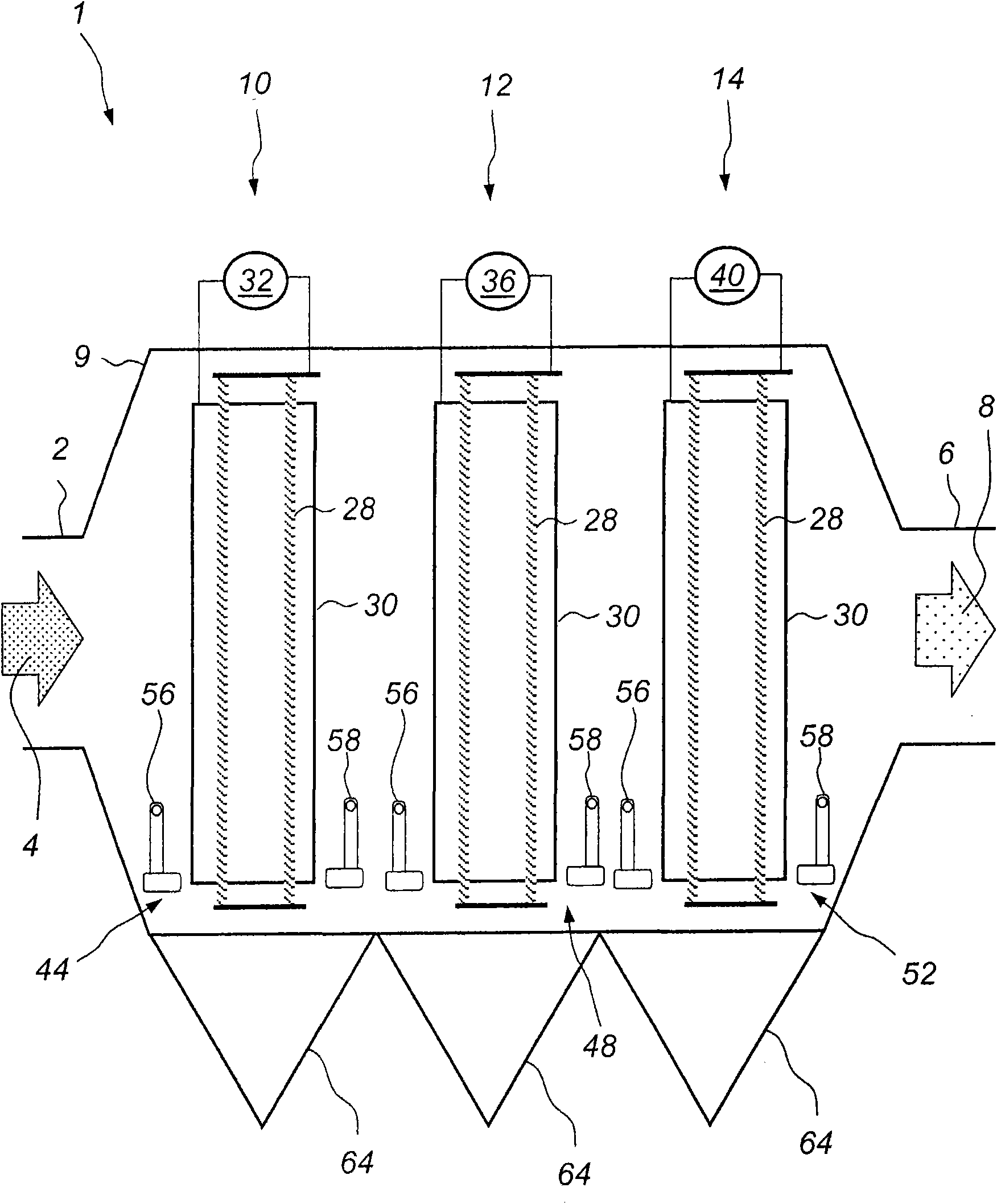

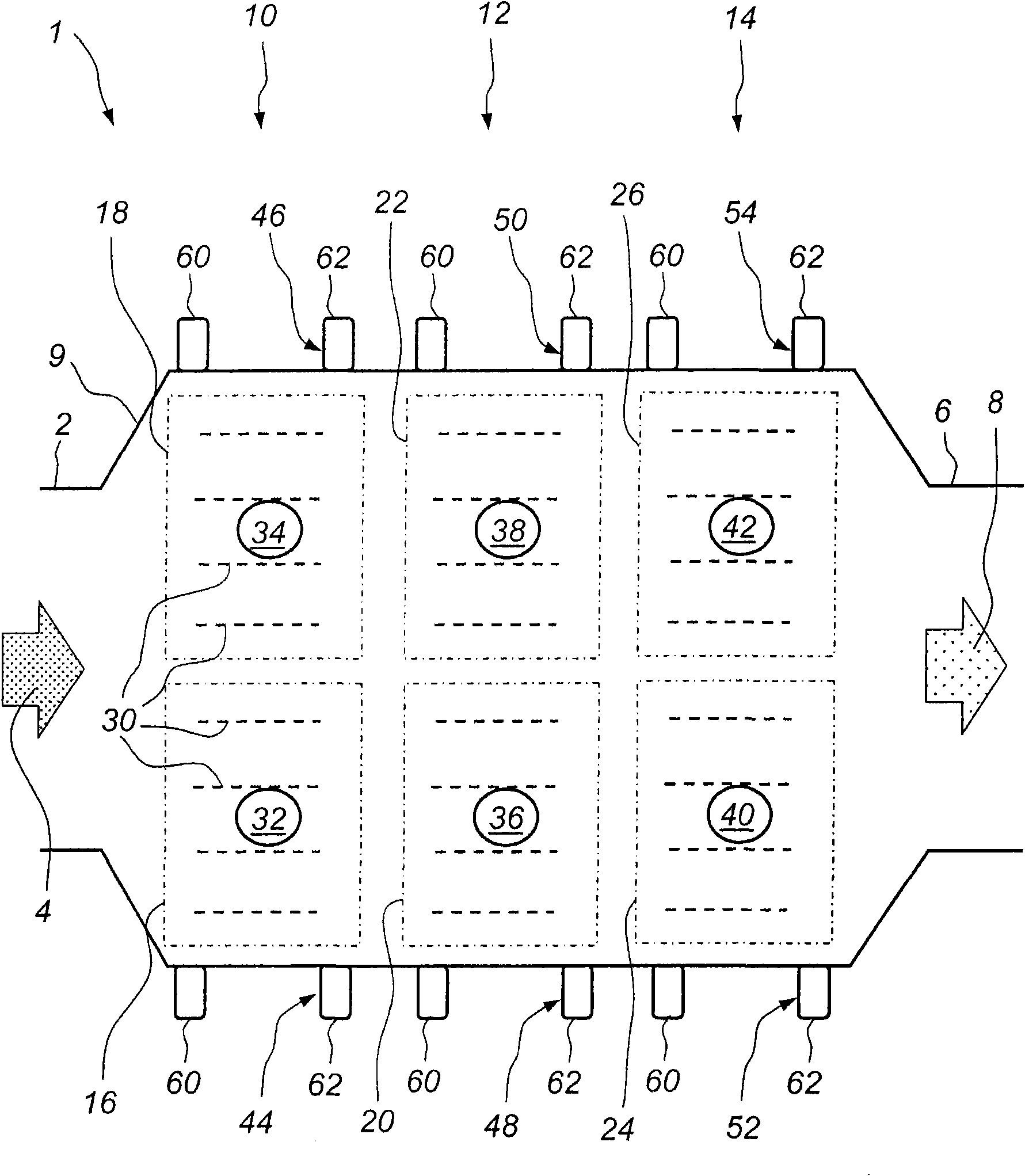

[0037] figure 1 An electrostatic precipitator (ESP) 1 is schematically shown viewed in side cross-section. figure 2 The same electrostatic precipitator 1 is shown viewed from above. The dust collector 1 has an inlet 2 for a flue gas 4 and an outlet 6 for a flue gas 8, the flue gas 4 contains dust particles, and the flue gas 8 has removed most of the dust particles. For example flue gas 4 may come from a boiler in which coal is fired. The precipitator 1 has a housing 9 in which a first zone 10 , a second zone 12 , a third and last zone 14 are provided. Each zone 10, 12, 14 has discharge and collection electrode plates known in the art such as US Patent No. 4,502,872, which is incorporated herein by reference.

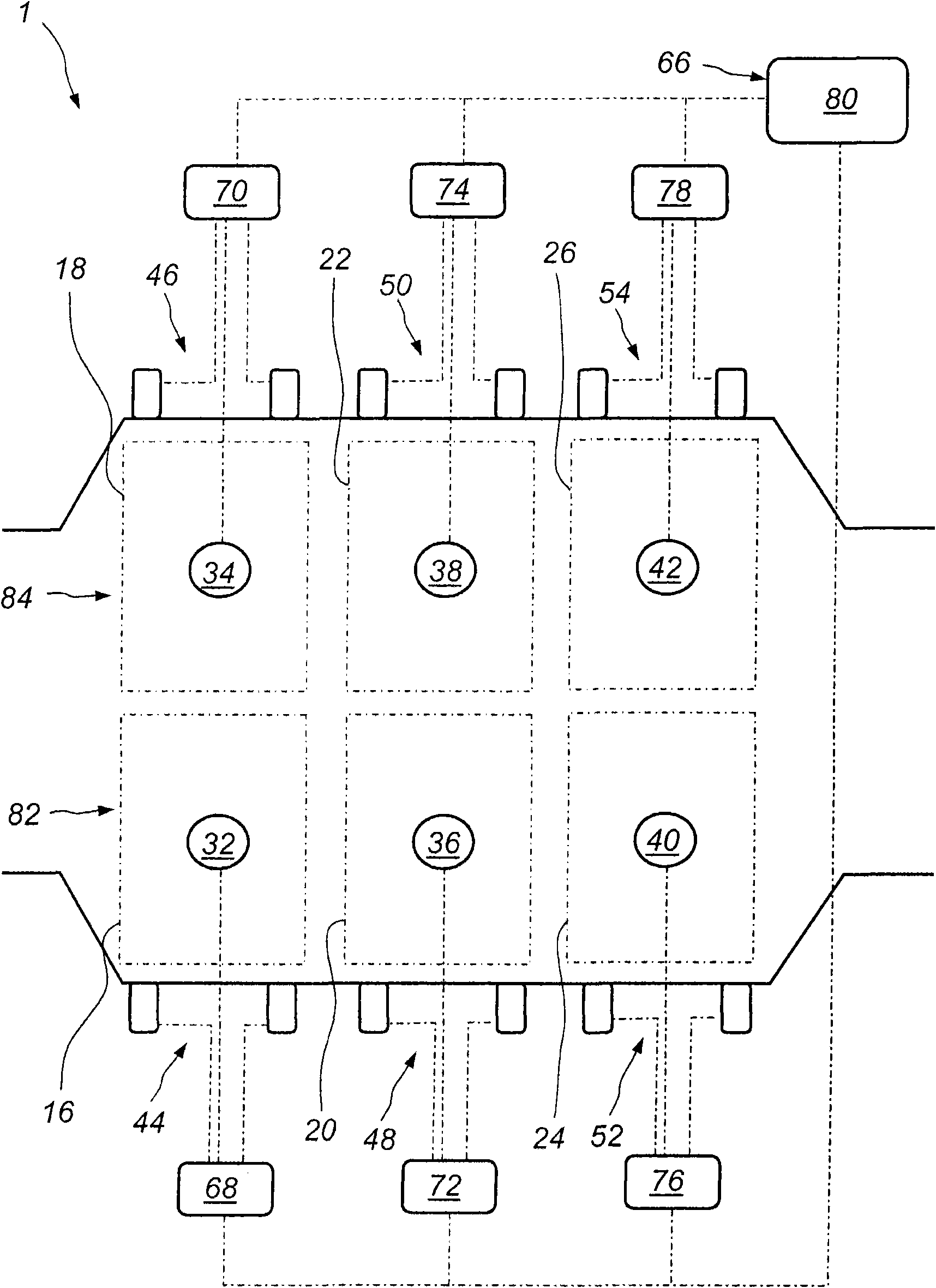

[0038] from figure 2 As can be clearly seen in , each zone 10, 12, 14 is divided into two parallel independent units called bus sections. A bus section is defined as having at least one dust collecting electrode plate, at least one discharge electrode and at least...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com