Birefringent film, multilayer film and image display

A birefringence and thin-film technology, which is applied in chemical instruments and methods, optics, instruments, etc., can solve problems such as dim and unclear pictures, and achieve the effect of excellent thin and light weight, excellent thin and light weight, and excellent viewing angle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0142] Hereinafter, examples are shown to further explain the present invention. However, the present invention is not limited to the following examples. In addition, each measurement method used in the Example is as follows.

[0143] (1) Determination method of thickness:

[0144]The thickness is measured by peeling off a part of the birefringent film formed on the surface of the substrate, and measuring the substrate and the birefringent film using a three-dimensional non-contact surface profile measurement system (manufactured by Ryoka System, product name "Micromap MM5200") height difference.

[0145] (2) Measurement method of transmittance (T[590]):

[0146] T[590] was measured at 23° C. using a brand name “U-4100” manufactured by Hitachi, Ltd. The measurement wavelength is 380nm to 780nm, with 590nm as the representative value.

[0147] (3)Δn xy [590], Δn xz Determination of [590], nx, ny, nz, Re[590], Rth[590] and Nz coefficients:

[0148] Re[590] etc. measured ...

Synthetic example 1

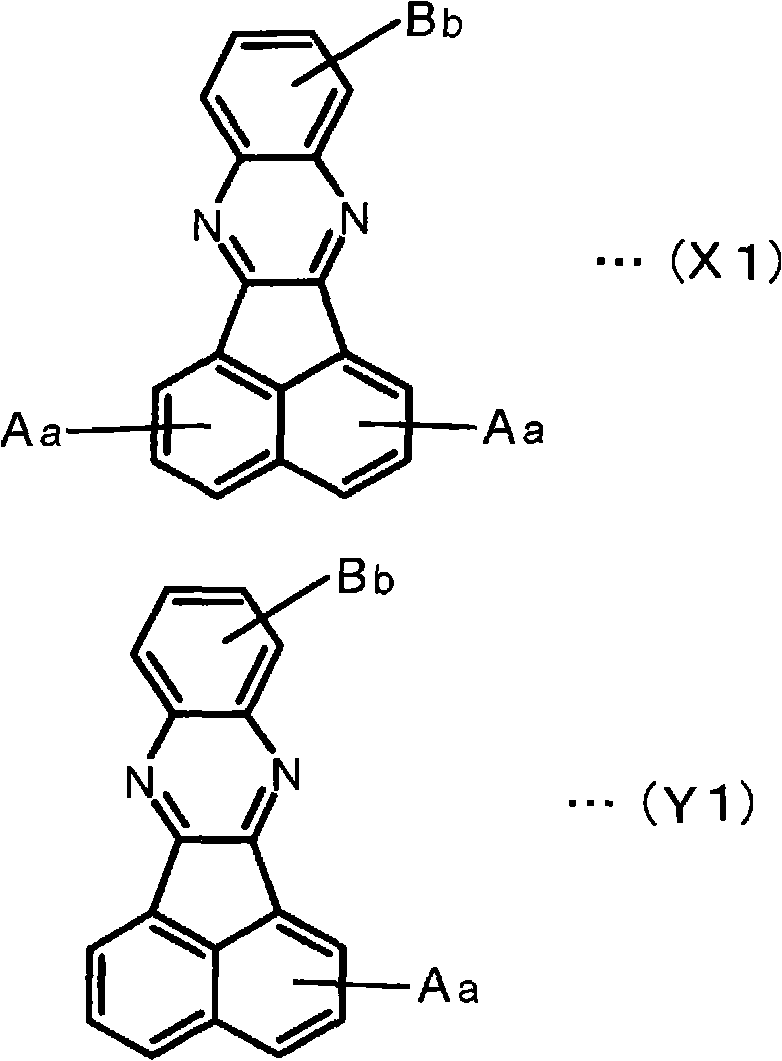

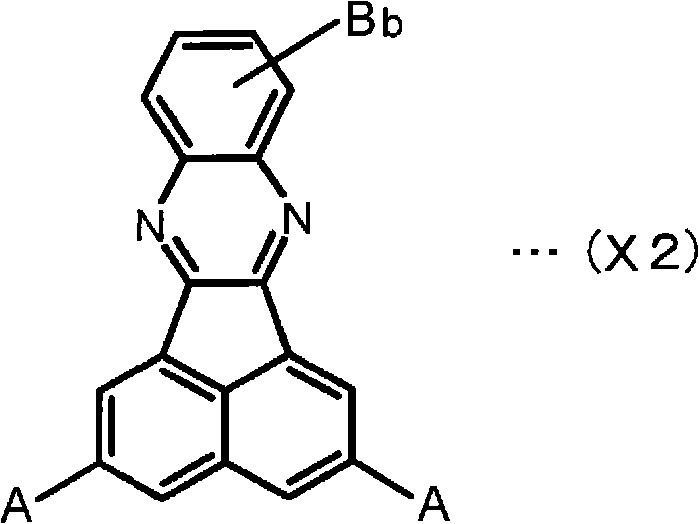

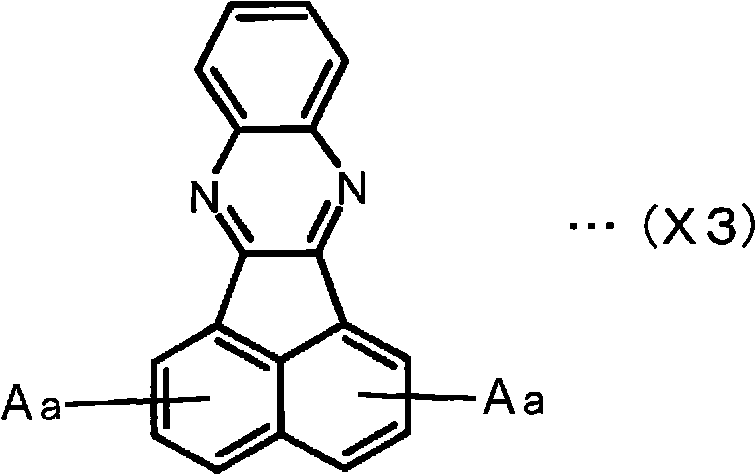

[0156]

[0157] 5 liters of glacial acetic acid and 490 g of purified acenaphthoquinone were added to a reaction vessel equipped with a stirrer, and stirred for 15 minutes under nitrogen bubbling to obtain an acenaphthoquinone solution. Similarly, 7.5 liters of glacial acetic acid and 275 g of o-phenylenediamine were added to another reaction container equipped with a stirrer, and stirred for 15 minutes under nitrogen bubbling to obtain an o-phenylenediamine solution. Then, while stirring under a nitrogen atmosphere, the o-phenylenediamine solution was slowly added to the acenaphthoquinone solution over 1 hour, and then stirring was continued for 3 hours to allow a reaction. After adding ion-exchanged water to the obtained reaction liquid, the precipitate was filtered to obtain a crude product containing acenaphtho[1,2-b]quinoxaline. The crude product was recrystallized and purified from hot glacial acetic acid.

Synthetic example 2

[0159]

[0160] As shown in the following reaction pathway, the acenaphtho[1,2-b]quinoxaline of 300 g obtained in the above synthesis example 1 was added to 30% oleum (2.1 liters), and after stirring at room temperature for 24 hours, Heated to 125° C., stirred for 32 hours, and reacted. While maintaining the obtained solution at 40° C. to 50° C., 4.5 liters of ion-exchanged water was added for dilution, and the mixture was further stirred for 3 hours. The precipitate was filtered and recrystallized with sulfuric acid to obtain acenaphtho[1,2-b]quinoxaline-2,5-disulfonic acid as the first derivative.

[0161] This reactant was dissolved in 30 liters of ion-exchanged water (conductivity: 0.1 μS / cm), and an aqueous sodium hydroxide solution was added to the aqueous solution to neutralize the aforementioned aqueous solution. The obtained aqueous solution was put into a supply tank, and was carried out while adding reverse osmosis water using a high-pressure RO element test devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com